Flour swing screen

Flour swing screen is a vibrating screen specially used for sieving flour. Through the vibration of the screen, impurities and flour lumps in the flour are sieved out to achieve the purpose of purifying the flour. The flour oscillating screen is an indispensable equipment in the flour processing industry and plays an important role in the flour processing industry. Its main function is to sieve out impurities and flour lumps in the flour to ensure the purity and quality of the flour.

Video of flour swing screen

How does the flour swing screen work?

Flour swing screen drives the eccentric mechanism through the motor, making the screen box produce horizontal, vertical and inclined three-dimensional swinging motion. The flour enters the screen box from the feed inlet and is subjected to the swinging action on the screen. The screen on the screen box separates the particles of different particle sizes in the flour. The larger particles are trapped on the screen, while the smaller particles pass through the screen and fall into the next layer or the discharge port.

What is a flour swing screen for?

1. Ensure product quality: Through screening, impurities in flour can be effectively removed, and the purity and sanitary quality of flour can be improved.

2. Increase product added value: By grading flour, different grades of flour can be produced to meet the needs of different consumers and increase product added value.

3. Extend product shelf life: Removing impurities can reduce the mildew of flour and extend its shelf life.

Structure of flour swing screen

Screen box: usually made of stainless steel, with the characteristics of corrosion resistance and easy cleaning.

Screen mesh: The screen mesh material is diverse, and screen meshes of different apertures can be selected according to the screening requirements.

Vibration motor: Provides vibration power to make the screen box vibrate.

Vibration reduction device: Reduces the impact of vibration on the equipment.

Discharge port: There are qualified product discharge port and impurity discharge port respectively.

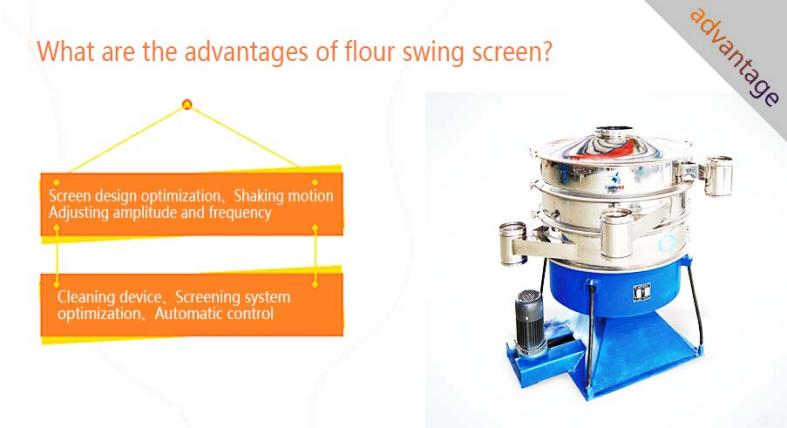

What are the advantages of flour swing screen?

1. Screen design optimization: The screen design of flour swing screen usually takes into account the characteristics of flour, such as fineness, humidity, etc., to reduce the possibility of screen clogging. Optimized screen design can improve screening efficiency and reduce maintenance frequency.

2. Shaking motion: The flour swing screen adopts shaking motion, so that the flour can be evenly distributed on the screen during the screening process, which helps to improve screening efficiency and uniformity.

3. Adjusting amplitude and frequency: The flour swing screen can control the movement during the screening process by adjusting the amplitude and frequency to adapt to flours of different particle sizes and properties, and improve screening efficiency and accuracy.

4. Cleaning device: The flour swing screen is usually equipped with a cleaning device to clean the screen regularly to prevent the screen from clogging and maintain screening efficiency.

5. Screening system optimization: The flour swing screen can form a complete screening system with other equipment (such as dust collector, conveying equipment), and improve the overall screening efficiency and product quality by optimizing the system design.

6. Automatic control: Some flour swing screen equipment can realize automatic control, automatically adjust the operating status according to the set parameters, improve production efficiency and reduce human operation errors.

Flour swing screen mesh

Application of flour oscillating screen

1. The primary stage of flour processing: In the first step of flour processing, after the wheat is ground into coarse powder, the oscillating screen is used to remove impurities such as bran, stones, weeds, etc., to provide high-quality raw materials for subsequent fine processing. The coarse powder is graded according to the particle size to obtain flour of different particle sizes to meet the needs of different uses.

2. Flour refining: After the fine grinding process, the oscillating screen is used to remove fine impurities such as metal chips, fibers, etc., to improve the purity of the flour, and to sieve different grades of flour. According to different uses, the flour is divided into special first-class flour, first-class flour, second-class flour, etc. to meet the needs of different consumers.

3. Pre-packaging treatment of flour: Before packaging, the oscillating screen is used to remove the flour clumps in the flour to ensure the quality of the packaged products, sieve out the fine dust, and prevent the packaging bags from being damaged.

4. Production of flour for special purposes: For flour used for baking, its particle size distribution needs to be strictly controlled to ensure the taste and quality of the baked products. Baby food has extremely high requirements for the purity of flour, and it needs to be sieved many times to remove all impurities.

Flour swing screen plays an important role in the flour processing industry. Through screening, it can effectively remove impurities in the flour and improve the quality of the flour. When choosing a flour sifter, you need to choose a suitable model according to actual needs.

-

Fully sealed structure, no powder overflow, no liquid overflow

-

Remove lumps and debris in flour, improve flour quality

-

For safe sieving and precise grading of liquids, powders and granules, suitable for plants and factories that need to handle large volumes of products

-

For separation of different particle sizes in the same product, safe screening to eliminate foreign matter, solid-liquid separation, etc.

-

Chemical catalyst vibrating screen

Chemical catalyst vibrating screen is a device specially used for screening and grading chemical catalyst...

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Standard test sieve

Standard test sieves are precision mesh screens used to separate particles based on size in various industries ...

-

Standard test sieve

Foam particle straight screen is a special device for screening foam particles. It is mainly used to classify...

-

Four-layer vibrating screen

Four-layer vibrating screen is a vibrating screening device with a four-layer screen structure. It is used for...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.