Four-layer vibrating screen

What is a four-layer vibrating screen?

Four-layer vibrating screen is a vibrating screening device with a four-layer screen structure. It is used for material classification, screening and filtering. It is mainly used for classification, screening and impurity removal of various granular and powdery materials. It is widely used in mining, metallurgy, chemical industry, building materials and other industries. It generates vibration through a vibration motor or exciter to make the material move on the screen surface, thereby achieving classification of materials of different particle sizes.

Video of four-layer vibrating screen

How does the four-layer vibrating screen work?

The vibration generated by the vibration motor makes the screen box resonate, so that the material on the screen surface jumps on the screen surface and moves forward. The apertures on the screen are different. During the movement of the material, the material larger than the screen aperture is retained on the screen surface, and the material smaller than the screen aperture passes through the screen and falls into the next layer, and so on, finally achieving material classification.

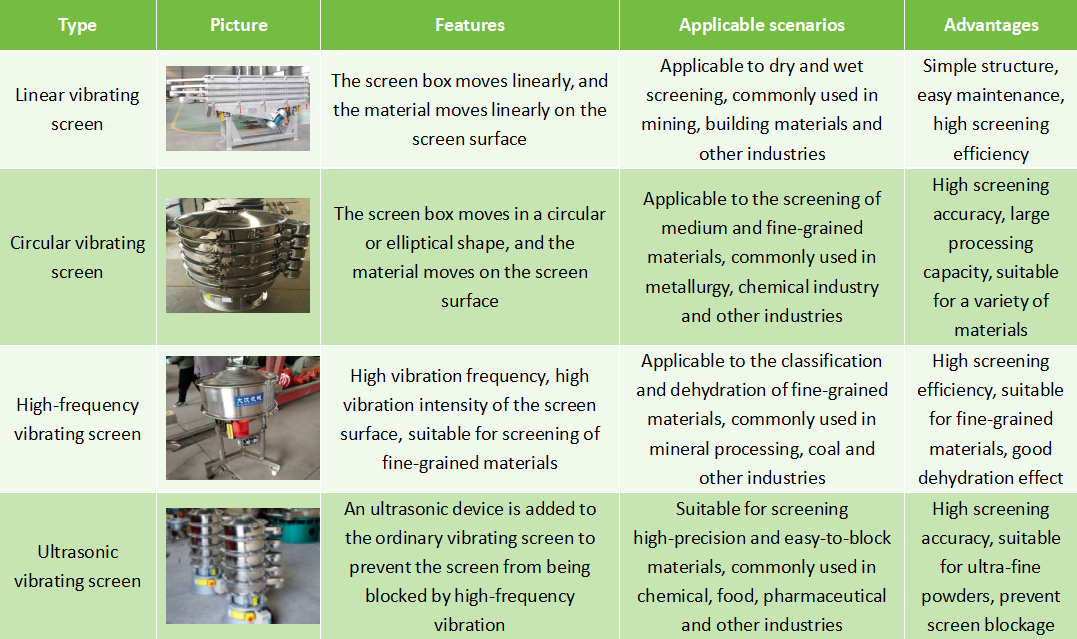

What are the different types of four-layer vibrating screen?

The structure of four-layer vibrating screen

Screen box: The screen box is the main body of the vibrating screen, usually made of stainless steel or carbon steel, with good corrosion resistance and wear resistance.

Screen mesh: The screen mesh is the core component of screening, usually made of stainless steel woven mesh or punching plate, and the aperture size is determined according to the screening requirements.

Vibration motor: Provides vibration power to make the screen box vibrate.

Vibration reduction device: Reduces the impact of vibration on the equipment and protects the equipment.

Support frame: Supports the entire screen machine to ensure its stable operation.

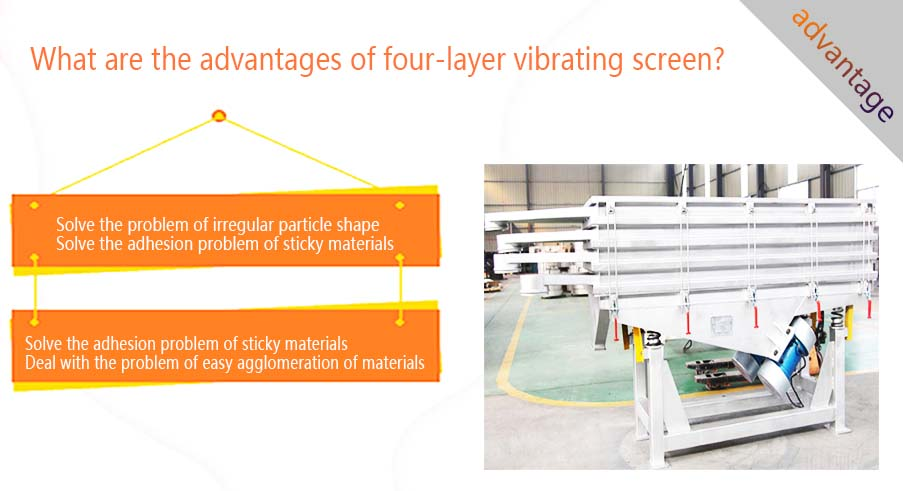

What are the advantages of a four-layer vibrating screen?

1. Solve the problem of irregular particle shape: For materials with irregular particle shapes, the four-layer vibrating screen can select the appropriate screen aperture and shape, and adjust the vibration parameters to achieve effective screening and grading.

2. Solve the adhesion problem of sticky materials: For sticky materials, the four-layer vibrating screen usually takes some measures to reduce adhesion, such as increasing the opening rate of the screen, using special anti-stick coatings, and adding vibration cleaning devices to ensure that the material can pass through the screen smoothly.

3. Deal with the clogging problem of high-humidity materials: High-humidity materials are prone to clogging and adhesion. The four-layer vibrating screen usually adopts heating, ventilation and drying to reduce the humidity of the material, or selects a special screen suitable for humidity materials to ensure the screening effect.

4. Deal with the problem of easy agglomeration of materials: Materials that are easy to agglomerate are prone to form agglomerates during the screening process. The four-layer vibrating screen can prevent material agglomeration and maintain the screening effect by reasonably designing the screen structure, adding a striking device or a vibration device, etc.

Application of four-layer vibrating screen

1. Mining and metallurgical industry: In the fields of ore, coal, metal minerals, etc., four-layer vibrating screen is used for screening, grading and removing impurities of ore, helping to improve the grade and purification effect of ore.

2. Building materials industry: In the production process of building materials such as cement, sandstone, concrete, etc., four-layer vibrating screen is used for screening, grading and removing impurities of granular materials to ensure product quality and production efficiency.

3. Chemical industry: In the production of chemical raw materials, plastic particles, pigments and other granular materials, four-layer vibrating screen can be used for screening, grading and particle size control to meet the particle size requirements of different products.

4. Food and beverage industry: In food processing and beverage production, four-layer vibrating screen is used for screening and grading of food raw materials, powders and particles to ensure product quality and food safety.

5. Pharmaceutical and cosmetic industry: In the production of pharmaceutical preparations and cosmetic raw materials, four-layer vibrating screen can be used for screening and grading of powders and particles to ensure the uniformity and purity of the product.

6. Environmental protection and waste treatment: In the fields of waste treatment, solid waste classification, etc., the four-layer vibrating screen can be used for waste screening and classification to achieve resource recovery and environmental protection treatment.

7. Agriculture and food processing: In the processing of agricultural products such as seeds, grains, and feed, the four-layer vibrating screen is used for screening, grading, and removing impurities of granular materials to improve product quality.

How to choose a four-layer vibrating screen?

Clarify material characteristics: Understand the physical and chemical properties of the material in detail.

Determine screening requirements: Determine the required screening accuracy, processing capacity and screening efficiency.

Select the appropriate type of screen: According to the material characteristics and screening requirements, select a circular vibrating screen, a linear vibrating screen or other types of vibrating screens.

Determine the screen material and aperture: Select the appropriate screen material and aperture according to the material characteristics and screening accuracy.

Determine the vibration parameters: Adjust the vibration frequency and amplitude according to the material characteristics and screening requirements.

What factors should be considered in the selection of four-layer vibrating screens?

Processing capacity: Determine the required processing capacity according to production needs, including the amount of material processed per hour and the required screening particle size range, and select a four-layer vibrating screen that meets the requirements.

Screening particle size: Determine the required screen aperture and screening accuracy according to the particle size range of the material to be screened, and ensure that the four-layer vibrating screen can achieve the required screening effect.

Material properties: Consider the viscosity, humidity, particle shape and other characteristics of the material, and select a four-layer vibrating screen suitable for processing such materials to ensure the screening effect and stable operation of the equipment.

Equipment quality: Select a four-layer vibrating screen brand and model with good quality and reliability to ensure stable operation of the equipment, strong durability, and reduce maintenance and failure rate.

Four-layer vibrating screen manufacturers

In general, as a highly efficient and multifunctional equipment, four-layer vibrating screen can effectively solve various problems in the material screening process, improve screening efficiency and product quality, and is suitable for screening and grading of a variety of granular materials. It is one of the important equipment commonly used in many fields.

-

Fully sealed structure, no powder overflow, no liquid overflow

-

Remove lumps and debris in flour, improve flour quality

-

For safe sieving and precise grading of liquids, powders and granules, suitable for plants and factories that need to handle large volumes of products

-

For separation of different particle sizes in the same product, safe screening to eliminate foreign matter, solid-liquid separation, etc.

-

Chemical catalyst vibrating screen

Chemical catalyst vibrating screen is a device specially used for screening and grading chemical catalyst...

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Standard test sieve

Standard test sieves are precision mesh screens used to separate particles based on size in various industries ...

-

Standard test sieve

Foam particle straight screen is a special device for screening foam particles. It is mainly used to classify...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.