Horizontal airflow screen

Horizontal airflow screen, also known as the cyclone screen, is a device specially used for screening fine powders and powder materials, and is particularly suitable for the classification of fine and ultra-fine powders. Its unique design and working principle enable it to perform well in processing materials that are difficult for traditional screening equipment to handle. It disperses and transports the material to the screen through airflow, and uses the combined effect of the vibration of the screen and the airflow to achieve the classification and screening of the material.

Horizontal airflow screen video

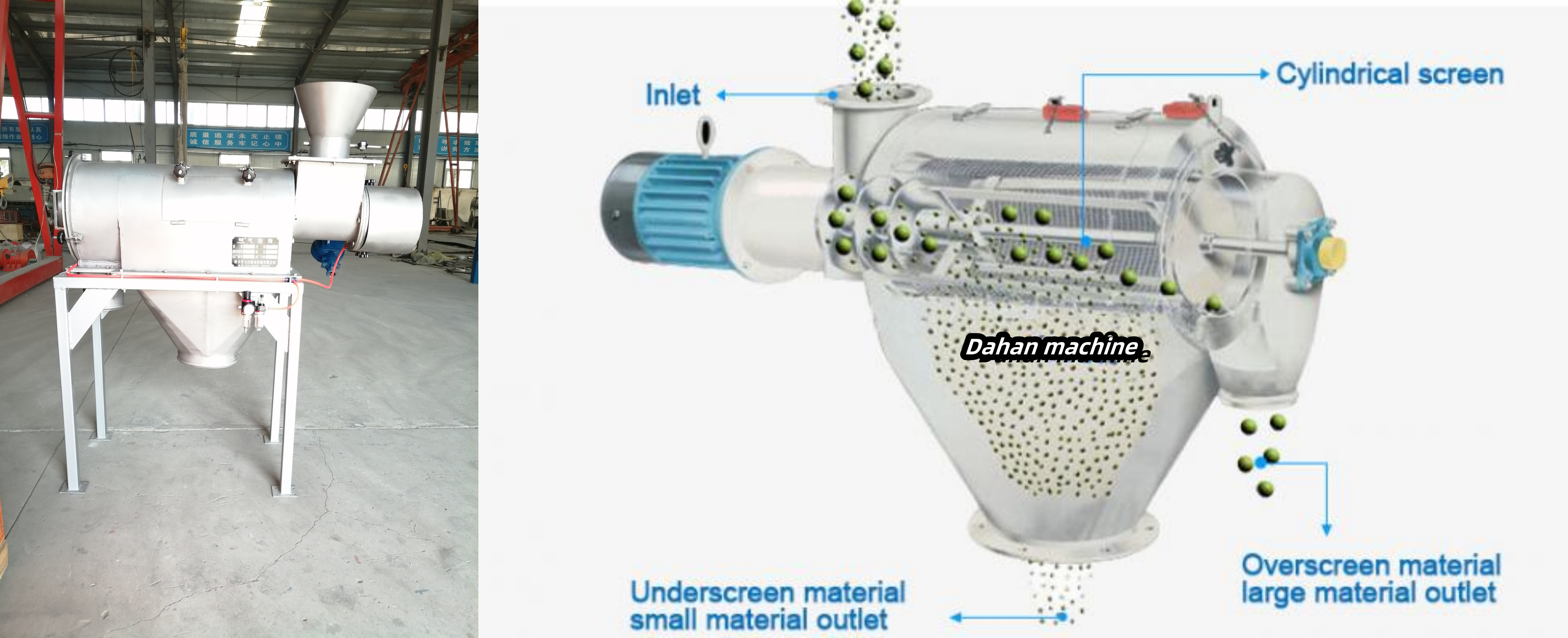

How does horizontal airflow screen work?

Material conveying and airflow mixing: The material enters the screen through the screw conveying system and is fully mixed with the airflow to form a mist.

Cyclone screening: The mixed material enters the cylindrical screen. Under the action of the high-speed rotating wind wheel, the material is subjected to the dual effects of centrifugal force and cyclone propulsion.

Material separation: Fine particles pass through the screen under the action of airflow and centrifugal force and are discharged from the fine material outlet. Larger particles are retained on the screen and discharged from the coarse material outlet along the cylinder wall.

What are horizontal airflow screens used for?

1、Fine screening of materials: Horizontal airflow screen can screen various fine powders and ultrafine powders with high precision, and can accurately separate particles of different particle sizes. For example, in the chemical industry, chemical raw materials such as calcium carbonate and talcum powder can be screened accurately to 325 mesh or even finer, ensuring uniform product particle size, meeting the strict requirements of different production processes for material particle size, and improving product quality and performance.

2、Solve the traditional screening problem: For light, easy to agglomerate, strong static electricity, high viscosity and other fine powders that are difficult to screen, horizontal airflow screen can effectively solve the problems of screen blockage and low screening efficiency. Horizontal airflow screen has strong processing capacity and high screening efficiency, which can significantly improve production efficiency and reduce production costs.

3、Remove impurities: In industries such as food and medicine that have extremely high requirements for hygiene and purity, horizontal airflow screen can effectively remove impurities and coarse particles in the material. For example, in flour production, it can screen out impurities such as bran and stones in flour to ensure the purity of flour and improve the taste and quality of food; in the pharmaceutical industry, it can screen raw materials, Chinese medicine powder, etc. to remove foreign matter and ensure the safety and effectiveness of medicines.

4、Increase production: The equipment has a large processing capacity and high screening efficiency. Compared with traditional screening equipment, the output of horizontal airflow screen can be increased several times. Because the airflow is used to push the material, the material moves quickly on the screen, which can meet the needs of large-scale production. For example, in the mining industry, when screening and grading mineral products such as kaolin and quartz sand, a large number of mineral products can be processed quickly and efficiently, improving production efficiency and increasing economic benefits.

Main features of horizontal airflow screen

1. High screening efficiency: Horizontal airflow screen uses airflow and centrifugal force for screening, which can effectively improve screening efficiency, especially for fine powder.

2. Strong processing capacity: Horizontal airflow screen has a large processing capacity and can meet the needs of industrial production.

3. High screening accuracy: Horizontal airflow screen can achieve high-precision screening to ensure product quality.

4. No clogging: The purge effect of airflow and centrifugal force can effectively prevent the screen from clogging.

5. Wide range of application: Horizontal airflow screen is suitable for screening of a variety of fine powder materials, including but not limited to: chemical raw materials, pharmaceutical powders, food additives, metal powders, and other fine powder materials.

What is the difference between airflow screen and horizontal airflow screen?

①Horizontal airflow screen

The screen is cylindrical and placed in the body. It screens the material through a specific working principle.

Suitable for screening materials that are easy to adhere and suspend

The screening mesh is generally 80 mesh - 600 mesh.

It is mainly used in chemical, non-metallic, metallurgical, food, medicine and other industries to screen various materials such as soda ash, polyethylene, resin powder, washing powder, rubber powder, Chinese medicine powder, etc.

②Airflow screen

It uses the characteristics of small and light powder particles, easy to float and good fluidity to fully diffuse them into the airflow. The powder passes through the screen with the airflow in turn to achieve screening.

High screening efficiency, large output, precise fineness, no oversize mixing phenomenon.

The screening mesh range is usually within 80-500 mesh

It is widely used in various difficult-to-screen fine powders, such as light calcium powder, active calcium powder, starch, Chinese medicine powder, fly ash, zinc powder, etc.

Application of horizontal airflow screen

1. Chemical industry: used for screening and grading chemical raw materials such as calcium carbonate, talcum powder, pigment, resin powder, etc., to ensure the uniformity of product particle size and improve product quality.

2. Food industry: can screen food raw materials such as flour, starch, milk powder, powdered sugar, cocoa powder, etc., remove impurities and coarse particles, and ensure the taste and quality of food.

3. Pharmaceutical industry: often used for screening pharmaceutical intermediates, raw materials, Chinese medicine powder, etc., to ensure that the particle size of the medicine meets the production requirements and improve the stability and bioavailability of the medicine.

4. Mining industry: fine screening and grading of mineral products such as kaolin, graphite, quartz sand, etc., to improve the purity and added value of mineral products.

5. Other industries: in the plastics, rubber, coatings, building materials and other industries, various powder materials are screened to meet the particle size control requirements in the production process.

Horizontal airflow screen has important application value in various industries that require high-precision and high-efficiency screening of fine powders. It can not only improve product quality and production efficiency, but also improve the working environment, meeting the requirements of modern industry for efficient and environmentally friendly production.

-

The model of vibration sieve is divided into eight equipments with different dimensions from 400-2000mm.

-

Sieve machine is a general-purpose vibrating screening and filtering equipment. The main material is divided into SUS304 stainless steel or Q235A carbon steel.

-

For safe sieving and precise grading of liquids, powders and granules, suitable for plants and factories that need to handle large volumes of products

-

For separation of different particle sizes in the same product, safe screening to eliminate foreign matter, solid-liquid separation, etc.

-

Chemical catalyst vibrating screen

Chemical catalyst vibratinACg screen is a device specially used for screening and grading chemical catalyst...

-

Double layer rotary vibrating screen

Double layer rotary vibrating screen is a multifunctional and efficient screening equipment used for particle size classification...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Nylon sieve

Nylon sieve is a common screening tool, widely used in laboratories and industrial production, mainly used for screening...

-

Stainless steel straight screen

Stainless steel straight screen is an efficient and durable screening equipment, mainly used for rapid screening of powder or...

-

Stone powder vibrating screen

Drying sand vibrating screen is a screening device that uses the exciting force generated by the vibrating motor to...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.