Stone powder vibrating screen

Stone powder vibrating screen is a screening device that uses the exciting force generated by the vibrating motor to make the stone powder particles on the screen surface jump in the vertical direction and throw in the horizontal direction, thereby separating the stone powder particles according to their particle size. It is mainly used to screen and grade the stone powder obtained by crushing limestone, marble and other stones to meet the requirements of stone powder particle size distribution in different industries.

Video of the stone powder vibrating screen

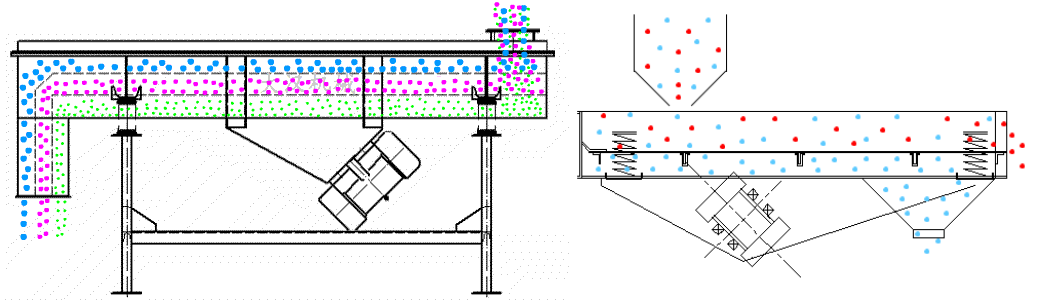

What is the principle of stone powder vibrating screen?

After the stone powder enters the screen surface, it is thrown up and jumps on the screen surface under the action of the exciting force and its own gravity. The stone powder with smaller particle size can smoothly pass through the pores of the screen and fall into the collection device below; while the stone powder with larger particle size is blocked on the screen, gradually moves toward the discharge port with the vibration of the screen, and is finally discharged from the screen machine, thus achieving the screening of the stone powder.

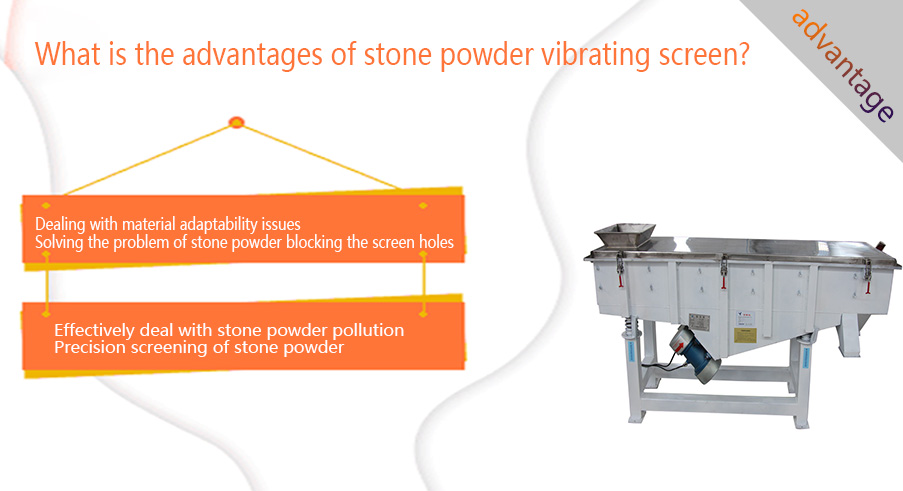

What is the advantages of stone powder vibrating screen?

1. Dealing with material adaptability issues: Stone powders of different properties, such as humidity and viscosity, affect the screening effect. The stone powder vibrating screen can adapt to stone powders of different properties by adjusting the vibration parameters. For stone powders with high humidity or viscosity, specially designed screens or auxiliary heating devices can be used.

2. Solving the problem of stone powder blocking the screen holes: Stone powder vibrating screen uses materials with high wear resistance and corrosion resistance, such as stainless steel screens, which can reduce the deformation of the screen and the reduction of the aperture due to wear and corrosion, and reduce the risk of blockage.

3. Effectively deal with stone powder pollution: The screen box of stone powder vibrating screen is designed as a fully enclosed structure to reduce the contact between stone powder and the outside air during the screening process and prevent dust from overflowing. Install sealing covers at the feed inlet, discharge port and other parts of the stone powder vibrating screen, and use flexible sealing materials such as rubber curtains and canvas to further enhance the sealing effect and reduce dust leakage.

4. Precision screening of stone powder: The particle size distribution of stone powder needs to be precisely controlled, and ordinary screening equipment is difficult to meet the requirements. Stone powder vibrating screen can select screens with different apertures according to needs to achieve precise screening.

What is stone powder vibrating screen used for?

1. Quarry: Stone powder vibrating screen screens the stone powder after mining and crushing, and separates stone powder of different particle sizes to meet the needs of different building materials.

2. Mineral processing industry: Stone powder vibrating screen screens and grades the ore, which is helpful for the subsequent mineral processing process and improves the efficiency and quality of mineral processing.

3. Chemical industry: Stone powder vibrating screen screens the stone powder materials in the chemical raw materials to ensure the quality and performance of chemical products.

4. Building materials industry: Stone powder vibrating screen is used for the classification of various stone powders and mineral powders such as dry mortar, machine-made sand, natural sand, quartz sand, dolomite, calcite, potassium feldspar, etc.

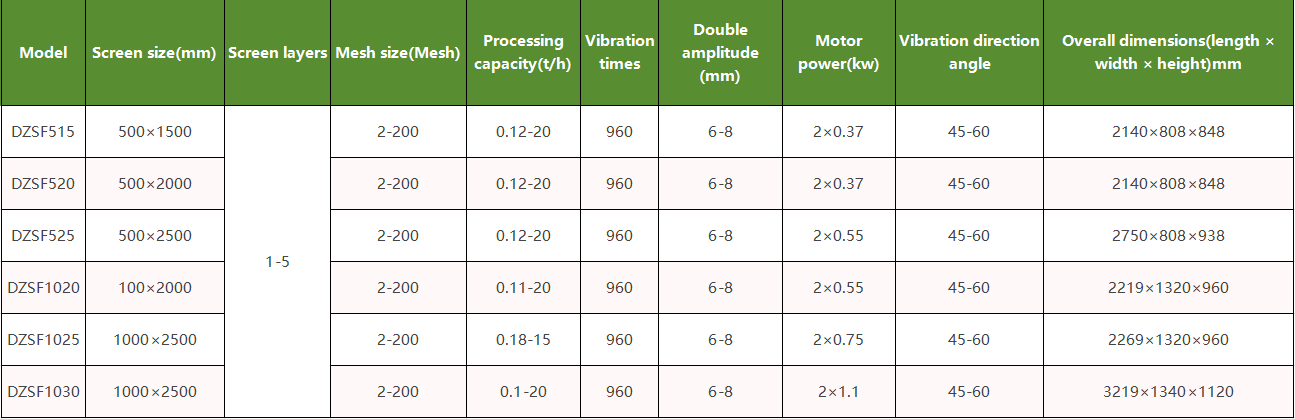

Size of stone powder vibrating screen

How to design a stone powder vibrating screen?

Screen selection: Choose a suitable screen for stone powder screening, including the size, material and shape of the screen hole. The choice of screen directly affects the final screening effect.

Vibration system design: Design the vibration system to provide appropriate vibration force and frequency to ensure that the stone powder can effectively pass through the screen during the screening process.

Structural design: Design a sturdy and durable structure to support the operation of the vibrating screen. Considering the impact of vibration on the equipment, it is necessary to ensure structural stability and safety.

Material selection: Choose wear-resistant and corrosion-resistant materials to manufacture the vibrating screen to ensure the long-term stable operation of the equipment

How to fix stone powder vibrating screen?

Select the appropriate screen aperture according to the particle size distribution and screening requirements of the stone powder. Regularly check and maintain the vibration motor, screen and other components to ensure the normal operation of the equipment. Pay attention to the ventilation and dust removal of the working environment to reduce dust pollution. Control the feed amount to avoid overloading the screen.

Stone powder vibrating screen manufacturer

Stone powder vibrating screen plays an important role in the screening and grading of stone powder particles, helping the industry to achieve particle size control, quality improvement and increased production efficiency.

-

Fully sealed structure, no powder overflow, no liquid overflow

-

Remove lumps and debris in flour, improve flour quality

-

For safe sieving and precise grading of liquids, powders and granules, suitable for plants and factories that need to handle large volumes of products

-

For separation of different particle sizes in the same product, safe screening to eliminate foreign matter, solid-liquid separation, etc.

-

Stone powder vibrating screen

Stone powder vibrating screen is used to classify stone powder particles or remove unnecessary imp ...

-

Chemical catalyst vibrating screen

Chemical catalyst vibrating screen is a device specially used for screening and grading chemical catalyst...

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Standard test sieve

Standard test sieves are precision mesh screens used to separate particles based on size in various industries ...

-

Drying sand vibrating screen

Drying sand vibrating screen is a vibrating screening device specially used for screening dried sand. It is mainly...

-

Carbon steel straight screen

Carbon steel straight screen is a common screening equipment, usually used in the industrial field to screen...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.