Nylon sieve

Nylon sieve is a common screening tool, widely used in laboratories and industrial production, mainly used for screening, grading and filtering of granular materials. The sieve is made of nylon material, which is lightweight, corrosion-resistant and wear-resistant, and is suitable for screening a variety of materials. The following is a detailed introduction to nylon sieve, including its characteristics, application scenarios and precautions for use.

How does the nylon sieve work?

Nylon sieve has sieve holes of specific size and shape. When materials containing particles of different sizes pass through the screen, particles with a size smaller than the sieve holes can pass through the sieve holes, while particles with a size larger than the sieve holes are retained on the screen, thereby achieving the separation of particles of different sizes.

How many types of sieves are there?

|

Material type |

Features |

Common uses |

Examples |

|

Metal |

High strength, durability, high temperature resistance |

Industrial screening, mineral screening, laboratory analysis |

Stainless steel screen, copper screen, iron screen |

|

Nylon |

Corrosion resistance, wear resistance, light weight, not easy to rust |

Laboratory particle analysis, food filtration, chemical screening |

Nylon test screen, nylon filter |

|

Plastic |

Low cost, light weight, acid and alkali resistance, non-conductive |

Home use, light industrial screening, small-scale experiments |

Polypropylene screen, PVC screen |

|

Ceramic |

High temperature resistance, corrosion resistance, strong chemical stability |

Special industries (such as ceramic powder screening), laboratories |

Ceramic screen |

|

Polyester |

High strength, chemical corrosion resistance, long life |

Textile industry, fine chemical screening |

Polyester screen |

|

Fiberglass |

High temperature resistance, corrosion resistance, good insulation |

Chemical and electronic industry screening |

Fiberglass screen |

Features of nylon sieve

1、Lightweight and durable: Nylon sieve is light, easy to carry and operate, and has high wear resistance and long service life.

2、Corrosion resistance: Nylon material has good tolerance to chemical substances such as acids and alkalis, and is suitable for screening corrosive materials.

3、Good flexibility: Nylon sieve has a certain elasticity, which can effectively prevent material blockage and is suitable for screening materials with high viscosity.

4、Uniform aperture: The aperture distribution of nylon sieve is uniform, the screening accuracy is high, and it is suitable for fine screening.

The structure of nylon sieve

Nylon sieve consists of a sieve frame, sieve mesh, sealing ring, fixing device, etc. The sieve frame is usually made of metal (such as stainless steel, aluminum alloy) or plastic, and is used to fix the sieve mesh and provide support. Common sieve frame shapes are round or square. The sieve mesh is made of nylon material, which is light, corrosion-resistant, and flexible.

What is the difference between a nylon sieve for industry and a nylon sieve?

Different uses

Nylon test sieves are mainly used for particle analysis and screening tests in laboratory environments, and are usually used for scientific research, quality inspection or standard analysis, such as particle size distribution tests in pharmaceutical, food, chemical, metallurgical and other industries. Nylon sieves are usually used for industrial or daily screening, suitable for filtering or classification of large particle materials, such as flour screening, soil filtration, etc.

Different precision requirements

The mesh number of the test sieve is accurate and meets national or international standards (such as ISO, ASTM, GB, etc.), and the aperture error is strictly controlled to ensure the accuracy and repeatability of experimental data. Nylon sieves are used for coarse screening, with large aperture errors and low screening accuracy requirements.

Different manufacturing standards

Nylon test sieves use high-precision screens and stainless steel or aluminum alloy frames to ensure wear resistance, chemical corrosion resistance and structural stability. Most nylon sieves are made of ordinary nylon materials, and the frame may be plastic or ordinary metal.

What are the advantages of nylon sieves?

Good water permeability: When filtering water or other liquid materials, nylon sieve has good water permeability, which can quickly let the liquid pass through the sieve, effectively intercept solid particles, and improve the filtering efficiency. It is often used in water treatment, liquid filtration and other fields.

High precision: It can be made into screens with different mesh numbers and apertures through precise weaving technology. The mesh number range is usually between dozens of meshes and hundreds of meshes, which can meet various fine screening needs and achieve high-precision grading and screening of materials.

Good flexibility: It has high flexibility and can withstand a certain degree of deformation without breaking during the screening process. It is suitable for screening some materials with certain viscosity or irregular shapes, and can effectively avoid the problem of material blockage or reduced screening efficiency due to the sieve being too hard.

Strong corrosion resistance: It has good tolerance to chemical substances such as acids and alkalis, can maintain stable performance in different chemical environments, is not easily corroded, and can be used to sieve various corrosive materials, such as chemical raw materials, electroplating liquids, etc., to extend the service life of the sieve.

What is nylon sieve used for?

Food industry: Nylon sieves are used for screening powdered or granular foods such as flour, starch, powdered sugar, and condiments to remove impurities and unqualified particles to ensure the quality and taste of food. For example, in the flour production process, these sieves can be used to screen out impurities such as bran, making the flour more delicate.

Pharmaceutical industry: Screening of drug particles, powders, etc. to ensure that the particle size of the drugs is uniform and meets the production process and quality standards. For example, in capsule production, drug particles are screened by nylon sieves to ensure that the size of particles loaded into the capsule is consistent, thereby ensuring the accuracy of drug dosage.

Water treatment industry: In the process of sewage treatment and drinking water purification, as a filter medium, it is used to intercept suspended matter, granular impurities, etc. in water to purify water quality. For example, in the filtration process of the water plant, nylon sieves can remove fine particles in the water to make the water quality meet the drinking standard.

Recommended nylon mesh number

20 mesh - 60 mesh: It is suitable for screening coarse particle materials, such as materials with larger particles or preliminary screening.

70 mesh - 120 mesh: It sieve is suitable for screening general particle materials, such as screening and filtering of general particle materials.

150 mesh - 300 mesh: It sieve is suitable for screening fine particle materials, such as screening and filtering with higher precision.

Above 300 mesh: It is suitable for screening ultra-fine particle materials, such as screening and filtering with very high precision.

How to clean Nylon sieve?

Check the condition of the sieve: Before cleaning it, carefully check whether the sieve is damaged, cracked or deformed.

Understand the characteristics of impurities: clarify the type, nature and adhesion of impurities on it in order to choose the appropriate cleaning method and tools.

Control the cleaning frequency: Do not clean sieve too frequently to avoid unnecessary damage to the sieve. The cleaning cycle should be reasonably determined according to the frequency of use and blockage of nylon sieve. Too frequent cleaning may cause fatigue of the sieve fiber and reduce the strength of sieve.

Maintain uniform cleaning: During the cleaning process, ensure that the entire surface of the sieve is cleaned evenly to avoid excessive local cleaning and incomplete cleaning of other parts.

Nylon sieve is an economical and practical screening tool, widely used in laboratories and industrial production. Through reasonable selection and use, the performance advantages of nylon sieve can be fully utilized to meet the screening needs of different materials. At the same time, paying attention to daily maintenance and care can extend the service life of sieve.

-

The model of vibration sieve is divided into eight equipments with different dimensions from 400-2000mm.

-

Sieve machine is a general-purpose vibrating screening and filtering equipment. The main material is divided into SUS304 stainless steel or Q235A carbon steel.

-

For safe sieving and precise grading of liquids, powders and granules, suitable for plants and factories that need to handle large volumes of products

-

For separation of different particle sizes in the same product, safe screening to eliminate foreign matter, solid-liquid separation, etc.

-

Chemical catalyst vibrating screen

Chemical catalyst vibratinACg screen is a device specially used for screening and grading chemical catalyst...

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

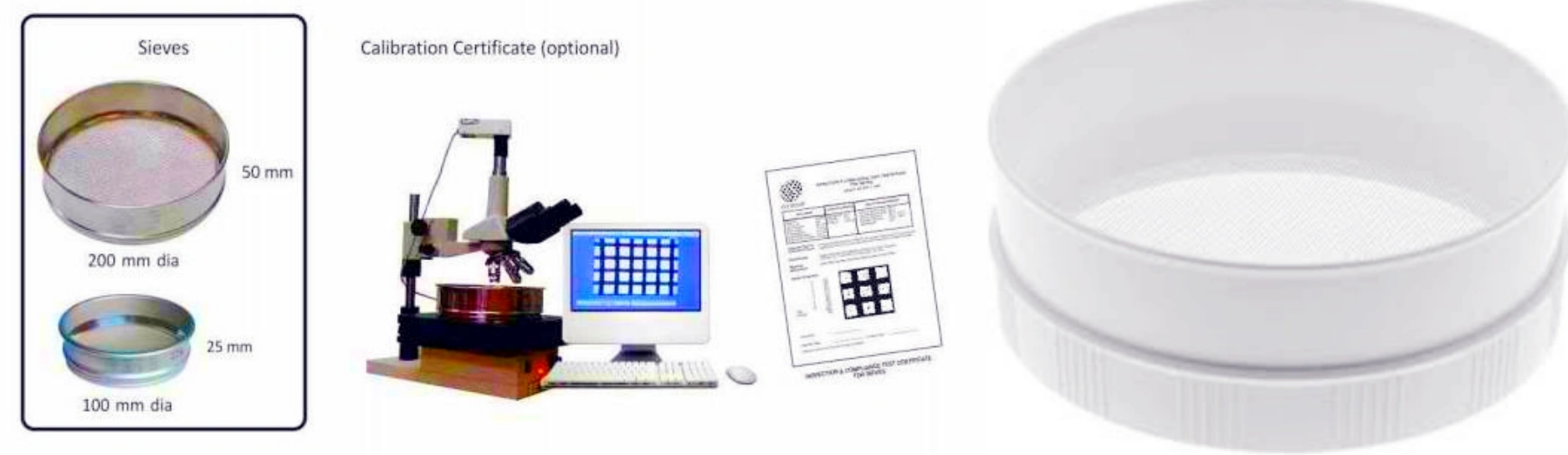

Standard test sieve

Standard test sieves are precision mesh screens used to separate particles based on size in various industries ...

-

Stainless steel straight-discharge screen

Drying sand vibrating screen is a vibrating screening device specially used for screening dried sand. It is mainly...

-

Medical screening machine

Stainless steel straight-discharge screen is an efficient and fast screening device, specially used for screening...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.