Polyethylene granule slap screen

Polyethylene granule slap screen is a vibrating screening device specially used for screening polyethylene (PE) granules. During the production and processing of polyethylene granules, the product quality may be affected due to uneven granule size or impurities. The slap screen can efficiently screen and grade polyethylene granules by combining slapping and vibration.

Polyethylene granule slap screen video

What is the working principle of the polyethylene granule slap screen?

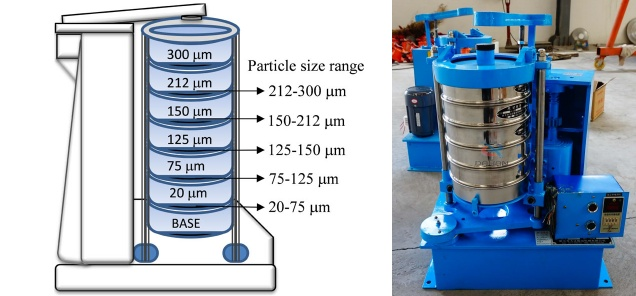

Polyethylene granule slap screen uses mechanical or electromagnetic drive to periodically slap the screen frame to evenly distribute the polyethylene particles on the screen. The vibration motor drives the screen frame to vibrate, causing the particles to move on the screen. Fine particles pass through the screen holes, while coarse particles move along the screen surface and are discharged from the discharge port. Through the multi-layer screen design, multi-level screening of polyethylene particles can be achieved, and particles of different granule sizes are discharged from different outlets.

The structure of polyethylene granule slap screen

Polyethylene granule slap screen usually consists of several parts such as screen frame, screen mesh, drive device, and body. The screen frame is used to fix the screen mesh. The screen mesh has different apertures and is used to separate materials of different granule sizes. The drive device provides vibration and slapping force, and the body supports the entire equipment.

What are the advantages of polyethylene granule slap screen?

1. Solve the adhesion problem of polyethylene particles: Polyethylene granule slap screen can generate a large impact force, which helps to break the adhesion between material particles and make polyethylene particles easier to pass through the sieve holes. By adjusting the vibration frequency and amplitude of the slap screen, the movement state of polyethylene particles on the screen surface can be controlled, thereby reducing the occurrence of adhesion.

2. Strong adaptability: Polyethylene granule slap screen is suitable for screening a variety of materials and granule sizes, including polyethylene particles, rubber particles, plastic powder, etc. This wide applicability enables it to meet the needs of different industries and fields. The structural design of polyethylene granule slap screen is reasonable and easy to disassemble and clean. This helps to keep the equipment in good operating condition and extend its service life.

3. Solve the problem of polyethylene granule blocking: Polyethylene granule slap screen is driven by a motor to make the screen body produce strong vibration and slapping effect. This vibration not only helps the polyethylene particles to jump and roll on the screen surface, but also effectively prevents the material from blocking the sieve holes. These screens have a large opening rate and good wear resistance. This design can reduce the accumulation and blockage of materials on the screen.

4. High screening accuracy of polyethylene particles: Polyethylene granule slap screen can make polyethylene particles more accurately sieve by granule size under the slapping and vibration of the screen, ensuring that polyethylene particles of different granule size ranges are effectively separated to meet the strict requirements of production on granule size.

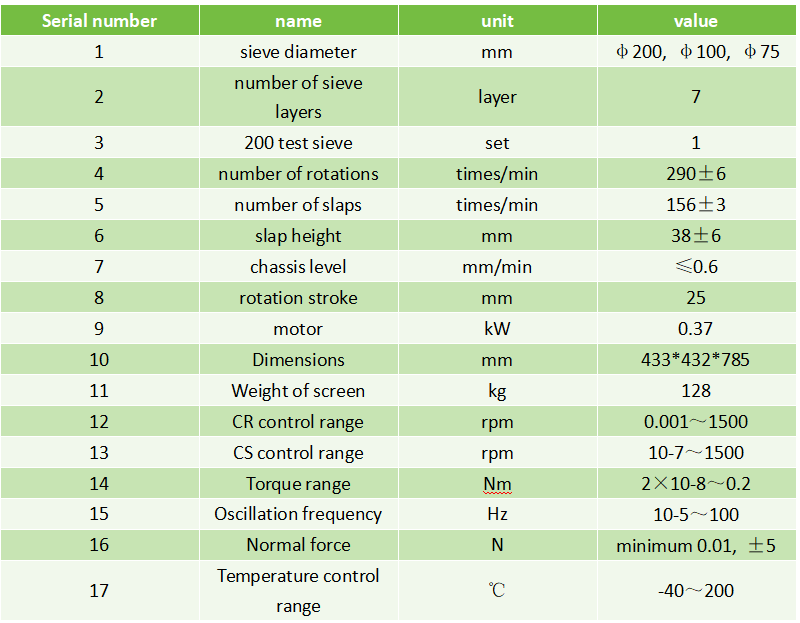

Parameters of polyethylene granule slap screen

Application of polyethylene granule slap screen

1. Polyethylene production plant: In the polyethylene production process, polyethylene granule slap screen can grade the polyethylene particles after granulation, separate particles of different granule sizes, meet the requirements of different products for raw material granule size, and ensure the quality of subsequent processed products.

2. Plastic processing enterprises: inspect and screen the purchased polyethylene particles. Polyethylene granule slap screen can remove particles that do not meet granule size requirements, ensure that the polyethylene particles put into production have uniform granule size, improve the quality stability of plastic products, and reduce product defects caused by uneven granule size.

3. Scientific research laboratory: used for granule size analysis experiments of polyethylene particles. Researchers use slap screens to screen polyethylene particles and accurately obtain particles of different granule size grades for subsequent performance testing and research, providing data support for the research and development and improvement of polyethylene materials.

Selection and use precautions of polyethylene granule slap screen

Screen selection: Select the appropriate mesh size according to the granule size requirements of polyethylene particles. The screen material should be wear-resistant and corrosion-resistant.

Slap frequency adjustment: Adjust the slap frequency according to the characteristics of polyethylene particles (such as humidity and viscosity) to ensure the best screening effect.

Equipment maintenance: Clean the screen and screen frame regularly to prevent material residue. Check the working status of the slap device and vibration motor to ensure the normal operation of the equipment.

Polyethylene granule slap screen can screen and grade polyethylene particles efficiently and accurately by combining slapping and vibration. It has the advantages of good anti-blocking performance, high screening accuracy and low noise, and is suitable for plastic processing, recycling industry and laboratories.

-

The model of vibration sieve is divided into eight equipments with different dimensions from 400-2000mm.

-

Sieve machine is a general-purpose vibrating screening and filtering equipment. The main material is divided into SUS304 stainless steel or Q235A carbon steel.

-

For safe sieving and precise grading of liquids, powders and granules, suitable for plants and factories that need to handle large volumes of products

-

For separation of different particle sizes in the same product, safe screening to eliminate foreign matter, solid-liquid separation, etc.

-

Chemical catalyst vibrating screen

Chemical catalyst vibratinACg screen is a device specially used for screening and grading chemical catalyst...

-

Double layer rotary vibrating screen

Double layer rotary vibrating screen is a multifunctional and efficient screening equipment used for particle size classification...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Nylon sieve

Nylon sieve is a common screening tool, widely used in laboratories and industrial production, mainly used for screening...

-

Stainless steel straight screen

Stainless steel straight screen is an efficient and durable screening equipment, mainly used for rapid screening of powder or...

-

Stone powder vibrating screen

Drying sand vibrating screen is a screening device that uses the exciting force generated by the vibrating motor to...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.