Three-dimensional rotary vibrating screen

Three-dimensional rotary vibrating screen, also known as the rotary vibrating screen or the three-dimensional vibrating screen, is a high-precision and high-efficiency screening equipment. It uses a unique vibration method to make the material do complex three-dimensional movement on the screen surface, thereby achieving efficient screening and grading. It is widely used in chemical, food, medicine, metallurgy and other industries.

Video of three-dimensional rotary vibrating screen

How does the three-dimensional rotary vibrating screen work?

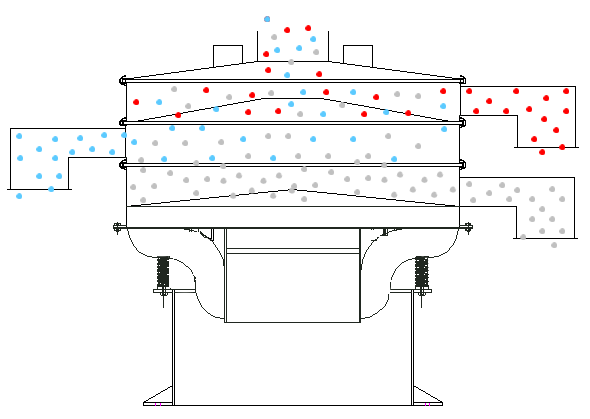

Three-dimensional rotary vibrating screen generates excitation force through the vibration motor, which makes the screen box move in three dimensions in the horizontal, vertical and inclined directions. This movement mode causes the material to be thrown, diffused and layered on the screen surface, thereby achieving efficient screening. The specific process is as follows:

1. Vibration motor: Generates excitation force to drive the screen box to vibrate in three dimensions.

2. Screen: The material is screened on the screen, and the material that meets the particle size requirements passes through the screen, while the material that does not meet the requirements continues to move on the screen surface.

3. Layering and diffusion: The material is layered on the screen surface, the fine particles move downward, and the coarse particles move upward, achieving efficient screening.

Main features of three-dimensional rotary vibrating screen

High screening accuracy: materials of different particle sizes can be accurately classified, and the screening accuracy can be as high as 500 mesh.

High efficiency and large output: the material running track is long, the screen surface utilization rate is high, and a large amount of material can be processed in a short time.

Easy operation and maintenance: simple structure, easy operation, fast net change, easy cleaning, stable equipment operation, low maintenance cost.

Good environmental performance: fully enclosed structure, effectively prevents dust flying and material leakage, and reduces pollution to the environment.

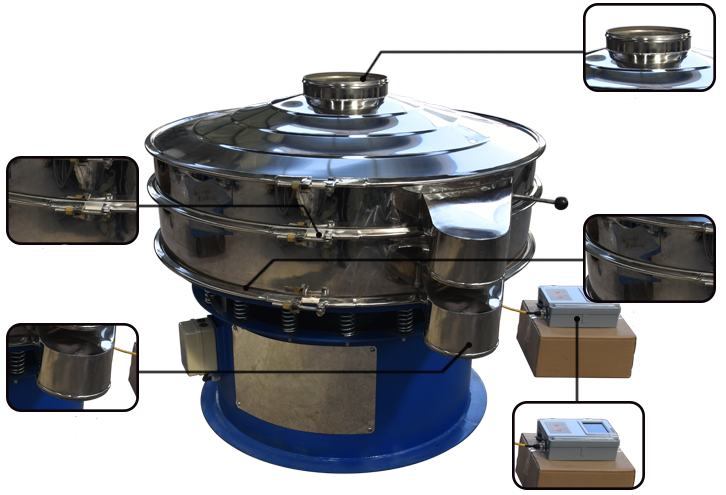

Structure of three-dimensional rotary vibrating screen

Screen box: carries the screen and materials for vibrating screening.

Screen: select screens of different mesh sizes according to the screening requirements.

Vibration motor: provides exciting force to drive the screen box to vibrate in three dimensions.

Base: supports the entire equipment to ensure stable operation.

Spring: connects the screen box and the base to play a shock-absorbing and supporting role.

Seal: prevents dust from spilling and ensures closed screening.

Feed port and discharge port: the material enters the screen box through the feed port, and the screened material is discharged through the discharge port.

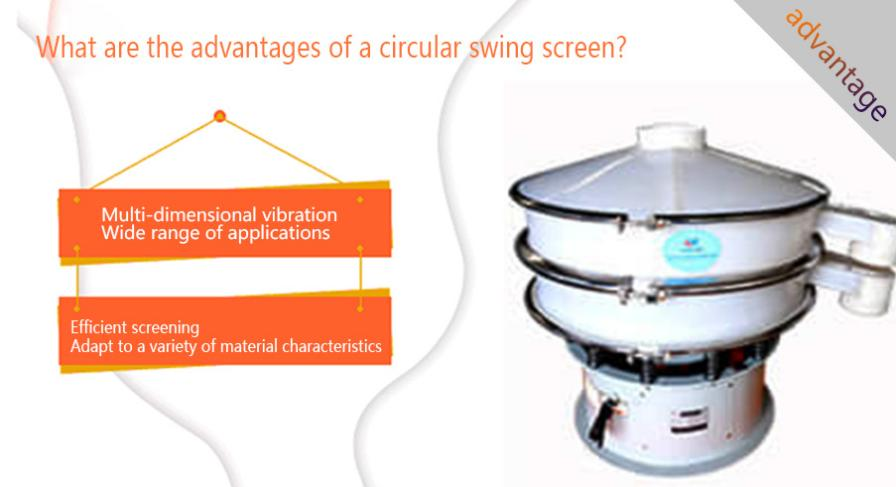

What are the advantages of the three-dimensional rotary vibrating screen?

1. Multi-dimensional vibration: The three-dimensional rotary vibrating screen can vibrate in three dimensions to achieve three-dimensional rotary vibration, so that the particles can be more evenly excited during the screening process, improving the screening efficiency.

2. Wide range of applications: The three-dimensional rotary vibrating screen is suitable for the screening of fine particles and can be widely used in chemical, food, pharmaceutical and other industries. It is particularly effective for particle screening processes with higher requirements.

3. Efficient screening: Due to the use of three-dimensional rotary vibration, the three-dimensional rotary vibrating screen has a high screening efficiency and can quickly and accurately classify particles according to the set requirements.

4. Adapt to a variety of material characteristics: Different materials (such as wet materials, dry materials, sticky materials, light materials, etc.) have different requirements for screening equipment. The three-dimensional vibrating screen is suitable for a variety of materials such as particles, powders, and liquids. By replacing the screen and adjusting the vibration parameters, it can adapt to the screening needs of different materials.

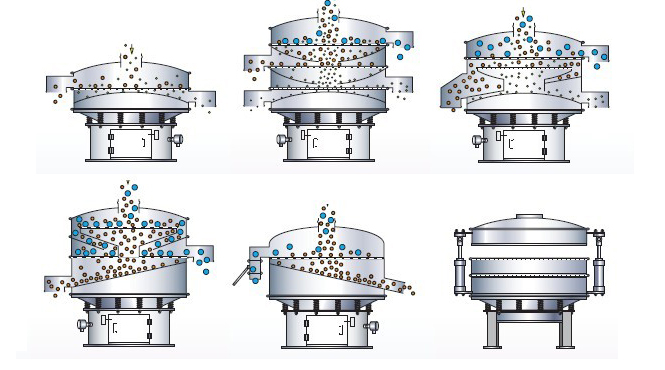

What can the three-dimensional rotary vibrating screen be used for?

Food industry: Three-dimensional rotary vibrating screen can grade flour according to different coarseness and fineness to produce flour suitable for making different pasta. For condiments such as pepper, chili powder, and pepper powder, the three-dimensional rotary vibrating screen can remove impurities and large particles, ensure the fineness and uniformity of the condiments, and improve product quality.

Chemical industry: In the production of paint, it can remove lumps, impurities, etc. in the paint, ensure the fineness and uniformity of the paint, so that the paint can be evenly applied when used, and grade plastic particles, separate plastic particles of different particle sizes, and meet the requirements of plastic particle size for the production of different plastic products.

Mining industry: Preliminary classification of mined ore, separation of ore particles of different particle sizes, to facilitate subsequent mineral processing, crushing, grinding and other processes. In the process of tailings treatment, the three-dimensional rotary vibrating screen is used to further recover useful minerals, improve resource utilization, and grade the tailings at the same time.

Abrasive industry: Screening of abrasives such as corundum and silicon carbide, grading by particle size, producing abrasive products of different specifications to meet the needs of grinding, lapping and other processing techniques, and facilitate subsequent comprehensive utilization.

Electronics industry: In the production of electronic components, it is used to screen raw materials such as electronic slurry and ceramic powder to ensure uniform particle size of the raw materials, which is conducive to improving the performance and quality of electronic components.

Selection suggestions for three-dimensional rotary vibrating screen

Material characteristics: including particle size, humidity, viscosity, etc.

Screening accuracy: select the appropriate screen mesh according to needs.

Processing capacity: select the appropriate equipment model according to production needs.

Material selection: select stainless steel or other material screens according to material characteristics.

Three-dimensional rotary vibrating screen has become one of the indispensable equipment in various industries through its efficient screening ability and wide application fields, effectively solving the problems in the material screening process. Whether it is ordinary materials or special materials, the three-dimensional vibrating screen can provide a reliable screening solution.

-

Fully sealed structure, no powder overflow, no liquid overflow

-

Remove lumps and debris in flour, improve flour quality

-

For safe sieving and precise grading of liquids, powders and granules, suitable for plants and factories that need to handle large volumes of products

-

For separation of different particle sizes in the same product, safe screening to eliminate foreign matter, solid-liquid separation, etc.

-

Chemical catalyst vibrating screen

Chemical catalyst vibrating screen is a device specially used for screening and grading chemical catalyst...

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Standard test sieve

Standard test sieves are precision mesh screens used to separate particles based on size in various industries ...

-

Circular swing screen

Circular swing screen, also known as swing screen or shaking screen, is a low-frequency rotary vibration...

-

Sewage impurity removal vibrating screen

Sewage impurity removal vibrating screen is a device specially used to remove solid impurities in the sewage...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.