Tea seed grading linear vibrating screen

The tea seed grading linear vibrating screen is a key equipment used in the tea processing field for screening and grading tea seeds. Its core function is to achieve efficient separation of seeds through mechanical vibration, ensuring the uniformity and quality of seeds. This equipment is widely used in seed processing in industries such as tea, agricultural products, and grain. Based on the principle of linear vibration, the raw materials are sieved through multiple layers of screens, and tea seeds can be finely graded according to particle size.

What is the function of the tea seed grading linear vibrating screen?

The core function of the tea seed grading linear vibrating screen is to grade tea seeds by particle size through vibration screening technology to meet the needs of planting, breeding, or commercialization.

Multi level particle size screening: Tea seeds are accurately classified by size through multiple layers of sieves (such as 4mm, 3mm, 2mm), separating different grades of seeds to ensure standardization in planting or sales.

Efficient sorting: Using a vibration motor to drive high-frequency vibration of the screen surface, quickly separating seeds and impurities (such as broken leaves and sediment), and improving processing efficiency (such as 200kg/h to 1 ton/h).

Protecting seed integrity: Using low-frequency and medium amplitude vibration parameters (800-1500 times/minute, amplitude 2-4mm) and soft contact design (silicone wrapped mesh) to avoid seed damage and maintain germination rate.

What is the working principle of the tea seed grading linear vibrating screen

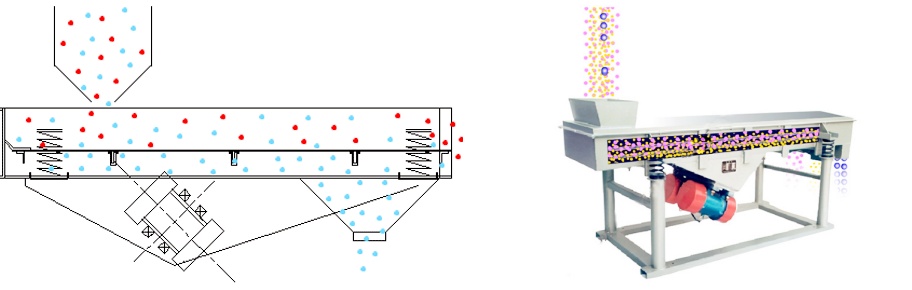

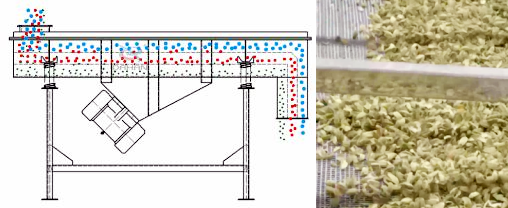

The tea seed grading linear vibrating screen is a specialized equipment for fine grading of tea seeds, which uses the principle of linear vibration to achieve screening operations.

① By using dual vibration motors to synchronously rotate in reverse, a composite vibration is generated in both horizontal and vertical directions, causing the tea seeds on the screen surface to move in a parabolic trajectory.

② Tea seeds automatically stratify under vibration, with small seeds falling through the sieve and larger seeds moving forward along the sieve surface, achieving multi-level grading.

③ By combining different aperture screens, multiple specifications of tea seeds (such as primary seeds, secondary seeds, impurities, etc.) can be separated simultaneously

The difference between tea seed grading linear vibrating screen and other screening equipment

|

Equipment type |

Linear vibrating screen for tea seed grading |

Rotary screen |

Circular vibrating screen |

Ultrasonic vibrating screen |

|

Image |

|

|

|

|

|

Motion trajectory |

Linear reciprocating motion |

Circular rotary motion |

Circular or elliptical vibration |

Superimposing high-frequency ultrasound on ordinary vibration |

|

Applicable materials |

Granular and powdery materials, especially suitable for materials that require precise size classification, such as tea seeds, etc. |

Material for rough classification and large processing volume, often used for garbage, ore, etc. |

Grading and dehydration of granular and powdery materials, with a wide range of applications |

Fine, difficult-to-screen powdery materials, materials that are easy to block the screen |

|

Grading accuracy |

High, accurate grading is achieved through multiple layers of screens with different mesh sizes |

Low, usually used for rough grading |

High, can be multi-level graded |

Very high, especially suitable for accurate grading of fine powders |

|

Processing volume |

Large, suitable for continuous operation |

Very large, suitable for large-scale processing |

Large, wide range of applications |

Relatively small |

|

Applicability to tea seeds |

Very suitable, can achieve accurate size grading and ensure tea seed quality |

Not very suitable, low grading accuracy, may damage tea seeds |

Can be used for preliminary grading, but the accuracy is not as good as linear vibrating screen |

Not commonly used, high cost |

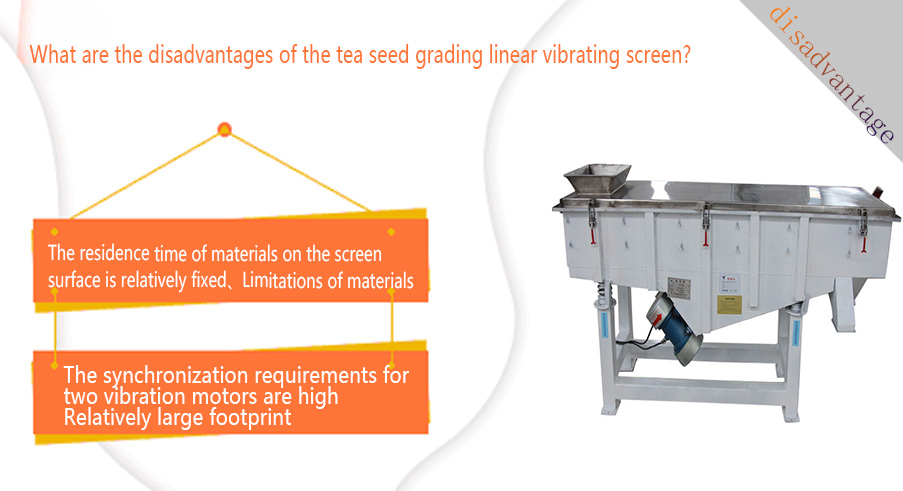

What are the disadvantages of the tea seed grading linear vibrating screen?

The residence time of materials on the screen surface is relatively fixed: linear motion makes the trajectory and residence time of materials on the screen surface relatively fixed, and adjustment is not as flexible as circular vibrating screens. Circular vibrating screens can easily change the motion state of materials on the screen surface by adjusting parameters such as the eccentric block of the exciter, in order to adapt to different screening needs.

Limitations of materials: For certain special shapes or materials with high viscosity, linear motion may not be as effective as circular motion in moving and separating them. When dealing with irregularly shaped or slightly viscous materials, the rolling and shaking of circular motion may be more conducive to material dispersion and passing through the sieve.

The synchronization requirements for two vibration motors are high: although the structure is relatively simple, in order to ensure stable linear motion, the synchronization of the two vibration motors is crucial. If there is a problem with synchronization, it may affect the screening effect and even damage the equipment.

Relatively large footprint: Due to its linear motion characteristics and usually longer screen surface design, linear vibrating screens often require larger installation space than circular vibrating screens with the same processing capacity.

Application of tea seed grading linear vibrating screen

Seed screening and treatment before seedling cultivation in tea gardens: In tea planting bases, tea research institutes, or seedling centers, it is necessary to ensure that the tea seeds are of uniform size, free of impurities, and full and healthy before sowing. The tea seed grading linear vibrating screen can be used to remove damaged and flattened seeds, finely grade large, medium, and small seeds, and improve germination rate and seedling uniformity.

The primary processing steps of tea seed processing enterprises: In enterprises engaged in tea seed sales or seed processing, the linear vibrating screen is the core equipment in the raw material cleaning line, used for screening large quantities of raw seeds, removing impurities such as broken leaves, sand particles, branches, etc; After precise grading, it is packaged and sold according to particle size to increase the market added value of commodity seeds.

Fine grading of tea seeds before export: For tea seeds exported for foreign trade, importing countries often have strict requirements for purity, uniformity, size specifications, etc. The tea seed grading linear vibrating screen can meet the particle size standardization grading before export; Improve packaging aesthetics and consistency in quality; Reduce manual picking costs and improve efficiency.

Tea seed research and variety improvement experiments: In the process of tea tree breeding, gene screening, and variety experiments, research institutes and university tea science laboratories require a small amount of high-precision screening equipment for small-scale tea seed experimental grading; Separate high-quality and inferior seed samples.

In summary, the tea seed grading linear vibrating screen plays a crucial role in the tea seed processing, as it lays the foundation for obtaining high-quality tea seeds through efficient and precise size grading and impurity removal. When making a purchase, it is necessary to consider the actual production capacity, grading requirements, and site conditions, and prioritize selecting models with dust-proof, easy to clean, and low-energy consumption characteristics.

-

Potato Starch Vibrating Screen

Granules, powders, and paddle materials can be used.

-

Granules, powders, and paddle materials can be used.

-

Meet the needs of large-scale and high-precision screening

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Pharmaceutical excipient powder vibrating screen

Pharmaceutical excipient powder vibrating screen is a screening device designed to meet the special physical and chemical properties of...

-

TPU Polymer Powder Sieving Machine

TPU polymer powder sieving machine is a mechanical equipment specially used for particle size classification, impurity removal or particle...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.