Sewage impurity removal vibrating screen

Sewage impurity removal vibrating screen is a device specially used to remove solid impurities in the sewage treatment process. It uses vibration screening to make the materials on the screen move relative to each other, and separates the solid particles, fibers, suspended matter and other impurities in the sewage, thereby achieving solid-liquid separation, improving water quality, and meeting the requirements of subsequent treatment or discharge. In the sewage treatment process, the vibrating screen plays a vital role, which can effectively remove suspended matter and impurities in the sewage, protect the subsequent treatment equipment, and improve the treatment efficiency.

Video of sewage impurity removal vibrating screen

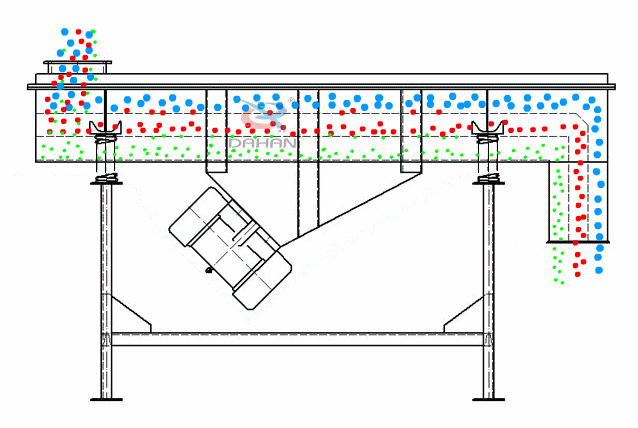

How does the sewage impurity removal vibrating screen work?

The vibrating motor drives the screen box to generate high-frequency vibration, causing the screen on the screen box to resonate. Sewage passes through the screen from the feed inlet. Under the action of vibration force, the liquid passes through the screen, while the solid particles are retained on the screen, thus achieving solid-liquid separation. Impurities move to the slag discharge port under the action of vibration, realizing automatic slag discharge and reducing the frequency of manual cleaning.

Main features of the sewage impurity removal vibrating screen

1. Efficient impurity removal: Through high-frequency vibration, solid impurities in sewage can be quickly separated with high treatment efficiency.

2. Corrosion-resistant material: The part of the equipment that contacts sewage is usually made of stainless steel (such as 304 or 316L) or anti-corrosion coating, which is corrosion-resistant and has a long service life.

3. Anti-clogging design: Use bouncing balls or ultrasonic cleaning devices to prevent screen clogging and ensure continuous operation.

4. Low noise and low energy consumption: The equipment runs smoothly, with low noise and low energy consumption, meeting environmental protection requirements.

5. Automated operation: Equipped with an automated control system to achieve continuous operation and reduce manual intervention.

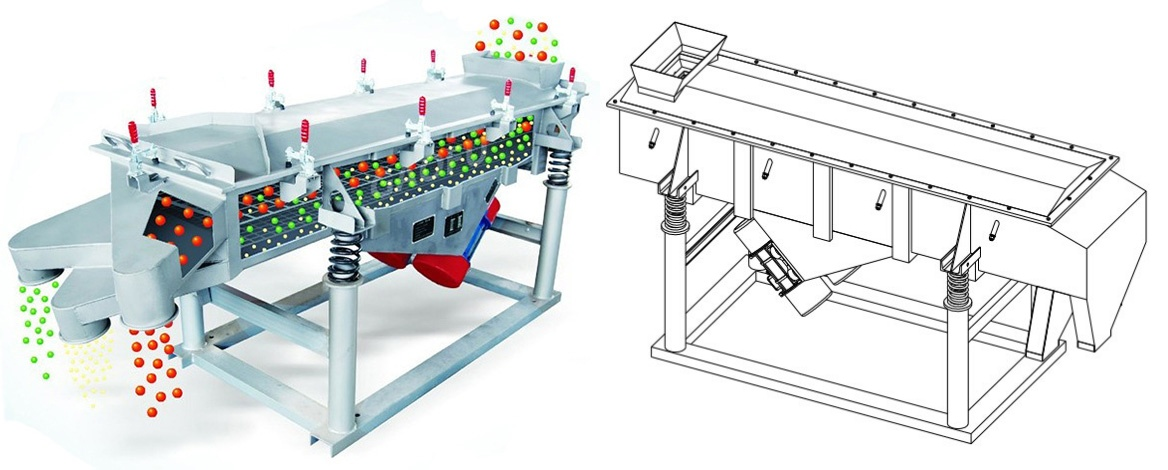

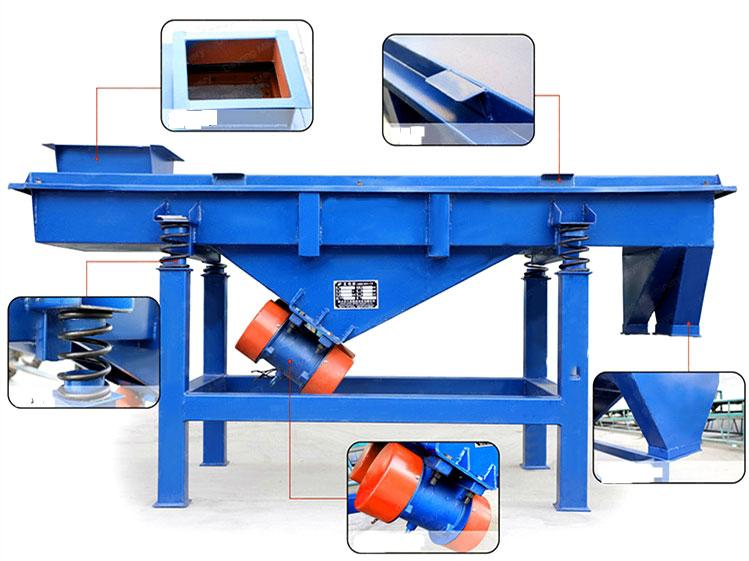

The structure of sewage impurity removal vibrating screen

Screen box: This is the main body of the vibrating screen, usually made of stainless steel, with the characteristics of corrosion resistance and wear resistance. Screens with different apertures are set in the screen box to separate solids and liquids.

Screen: The screen is the core component of the vibrating screen and directly affects the screening effect. The screen material is diverse, including stainless steel woven mesh, punching plate, etc., and the aperture size depends on the screening requirements.

Vibration motor: Provides vibration power to make the screen box resonate. The vibration motor is the heart of the vibrating screen, and its performance directly affects the screening effect.

Vibration damping device: Reduce the impact of vibration on the equipment, protect the equipment, and reduce noise. The vibration damping device usually uses rubber pads or springs.

Support frame: Support the entire screen machine to ensure its stable operation.

Feed inlet and discharge port: Used for sewage entry and discharge after solid-liquid separation, respectively.

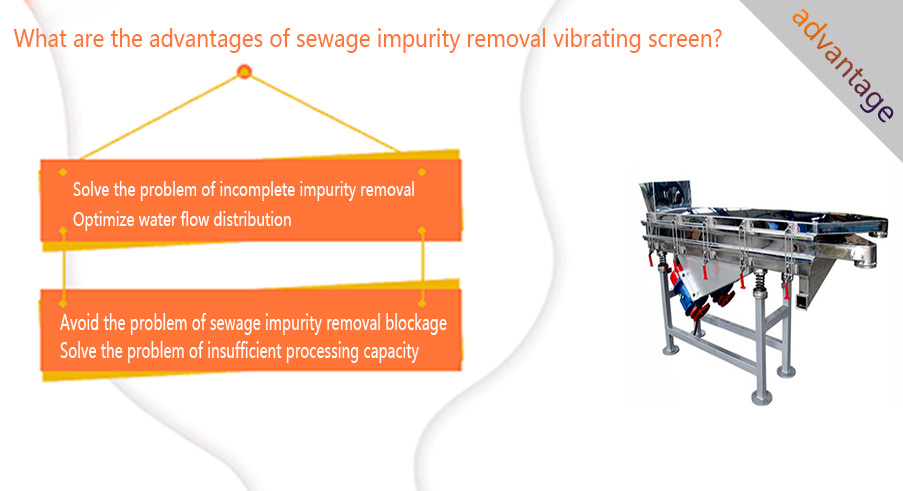

What are the advantages of sewage impurity removal vibrating screen?

1. Solve the problem of incomplete impurity removal: adopt a multi-layer screen structure, and the size of the screen hole gradually decreases from top to bottom. The sewage first passes through a large-aperture screen to remove larger impurities, and then passes through a small-aperture screen in turn to achieve gradual filtration of impurities of different particle sizes, thereby improving the thoroughness of impurity removal. The multi-layer screen structure increases the screening area, increases the contact time and area between the sewage and the screen, and gives more impurities a chance to be intercepted and removed.

2. Optimize water flow distribution: By designing a reasonable feeding device, the sewage is evenly distributed on the screen surface to avoid the situation where the local water flow is too fast or too slow, ensuring that the entire screen surface can fully play the screening role and improve the impurity removal efficiency.

3. Avoid the problem of sewage impurity removal blockage: The screen made of stainless steel and other materials can adapt to various complex chemical environments in sewage, reduce the deformation and damage of the screen caused by corrosion, and reduce the risk of blockage. For example, for sewage with more fibrous impurities, elliptical or rectangular screen holes can be used to make it easier for fibers to pass through the screen holes, reducing entanglement and blockage.

4. Solve the problem of insufficient processing capacity: The sewage impurity removal vibrating screen adopts a large processing capacity design, which can effectively deal with large-flow sewage and meet high processing requirements. It supports long-term continuous work and improves the overall processing capacity.

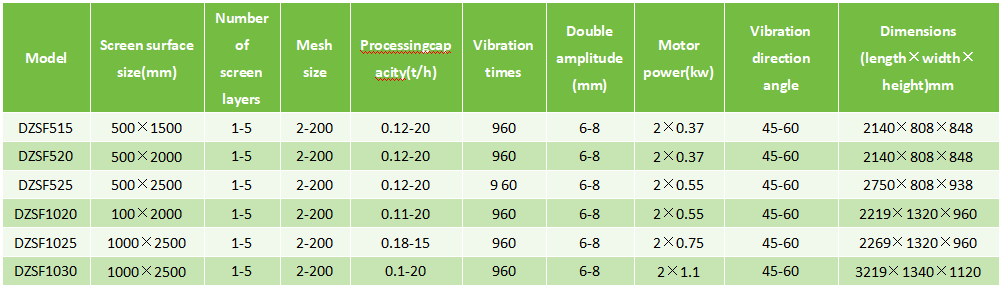

Technical parameters of sewage impurity removal vibrating screen

What is sewage impurity removal vibrating screen used for?

1. Sewage treatment plant: Before entering the biochemical treatment unit, remove large particles of impurities in the sewage, such as branches, plastic bags, etc., to protect subsequent equipment. The sewage impurity removal vibrating screen is used to remove solid particles, fibers, gravel and other impurities in the sewage to protect the subsequent treatment equipment from damage.

2. Municipal sewage treatment: Municipal sewage treatment is another important area of vibrating screen application. The sewage impurity removal vibrating screen can help remove solid waste, suspended matter and other impurities in municipal sewage, ensuring that the treated sewage meets the discharge standards and protects the environment.

3. Industrial wastewater treatment: The wastewater generated in the industrial production process may contain various harmful substances and solid particles. The sewage impurity removal vibrating screen can be used to remove these impurities, purify industrial wastewater, and prevent pollution to the environment.

4. Pre-screening of water treatment equipment: In water treatment equipment, the sewage impurity removal vibrating screen is often used as a pre-screening equipment to remove large particles of impurities in the incoming water, protect the normal operation of subsequent equipment, and extend the life of the equipment.

5. Agricultural wastewater treatment: Wastewater generated in agricultural production may contain pesticide residues, organic matter, etc. The sewage impurity removal vibrating screen can help remove these harmful substances, purify agricultural wastewater, and protect soil and water resources.

Sewage impurity removal vibrating screen is an indispensable equipment in the sewage treatment process. It can efficiently remove solid impurities, protect subsequent treatment equipment, and improve water quality. If you have specific needs, you can contact the manufacturer to obtain a customized solution

-

Fully sealed structure, no powder overflow, no liquid overflow

-

Remove lumps and debris in flour, improve flour quality

-

For safe sieving and precise grading of liquids, powders and granules, suitable for plants and factories that need to handle large volumes of products

-

For separation of different particle sizes in the same product, safe screening to eliminate foreign matter, solid-liquid separation, etc.

-

Chemical catalyst vibrating screen

Chemical catalyst vibrating screen is a device specially used for screening and grading chemical catalyst...

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Standard test sieve

Standard test sieves are precision mesh screens used to separate particles based on size in various industries ...

-

Washing powder vibrating screen

Washing powder vibrating screen is a device specially used for screening and removing impurities from washing powder...

-

Flour swing screen

Flour swing screen is a vibrating screen specially used for sieving flour. Through the vibration of the screen...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.