100-mesh vibrating slip screen

100-mesh vibrating slip screen can effectively separate fine particles with a particle size of less than 0.15 mm from coarse particles larger than this size. It is suitable for the classification of micro-powders and fine-grained materials. It is a high-precision and high-efficiency screening equipment. Through the combination of 100-mesh screen and vibration technology, it achieves accurate classification of fine particles. It is usually made of woven stainless steel or polyurethane and is designed to separate small particles in industries where accuracy and flow are critical.

100-mesh vibrating slip screen video

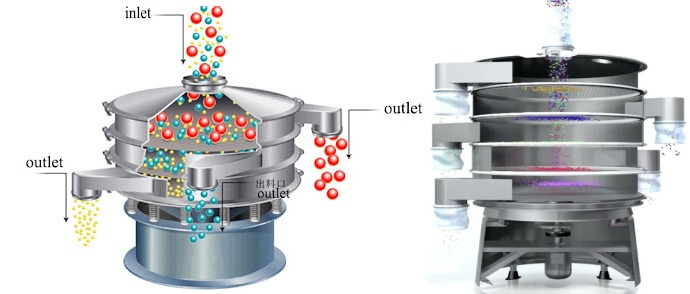

How does the 100-mesh vibrating slip screen work?

Vibration: A motor or vibrator creates high-frequency vibrations that are transmitted to the screen surface.

Lifting and lowering: Particles are lifted and then fall back onto the screen surface.

Forward movement: The 100-mesh vibrating slip screen pushes material forward, usually in a linear or circular motion.

Stratification: When material is vibrated, it is separated into layers based on particle size and density. Lighter or smaller particles move to the bottom and pass through the screen, while heavier or larger particles remain at the top.

What is the difference between 40 mesh screen and 100 mesh vibrating slip screen?

The main difference between a 40-mesh screen and a 100-mesh vibrating slip screen is the size of the screen holes, which directly affects their particle retention capacity, application range, and processing efficiency.

Mesh size and particle retention

40 mesh screen: has 40 openings per linear inch, resulting in a larger aperture size, allowing smaller particles to pass through.

100 mesh vibrating slide screen: has 100 openings per linear inch, with significantly smaller aperture size, providing finer filtration.

Scope of application

40 mesh screen: suitable for coarse screening tasks to separate larger particles, such as mining, agriculture or construction.

100 mesh vibrating slip screen: suitable for fine screening applications, including chemical processing, pharmaceutical and food production.

Processing efficiency and material flow

40 mesh screen: can handle higher throughput, resulting in faster material flow and reduced risk of clogging.

100 mesh vibrating slide screen: the screen is finer, the material processing speed is slower, and vibration is required to prevent the screen holes from clogging.

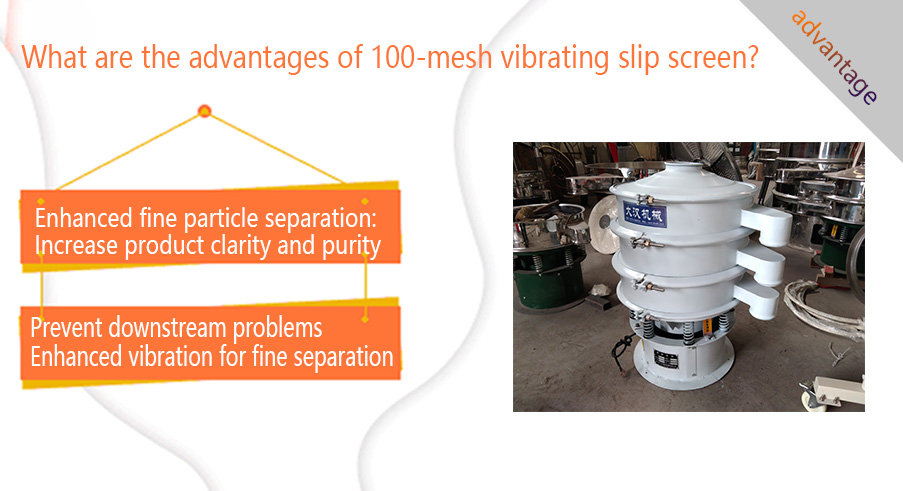

What are the advantages of 100-mesh vibrating slip screen?

Compared to other vibrating screens, 100-mesh vibrating slip screen has many key highlights, especially due to its fine mesh size design:

Enhanced fine particle separation: The equipment is able to efficiently separate relatively fine solid particles (usually larger than about 150 microns) from liquids or slurries. This separation effect is significantly higher than those coarse mesh vibrating screens (such as 40 mesh, 60 mesh) used to remove larger solid particles.

Increase product clarity and purity: By removing these finer suspended solids, the 100-mesh vibrating slip screen helps produce a clearer, purer liquid product with better visual appeal and potentially better downstream processing characteristics.

Prevent downstream problems: Removing particles around 100 mesh can prevent finer downstream equipment from clogging or damage, allowing medium-sized fine powders to pass through.

Enhanced vibration for fine separation: The vibration system used with the 100-mesh slip screen is usually designed with a higher frequency or specific vibration mode that can more effectively keep the fine mesh open and promote the movement of finer particles.

Application of 100-mesh vibrating slip screen

100-mesh vibrating slip screen is a kind of equipment widely used in particle material classification, solid-liquid separation and screening operations. Its core feature is that the mesh aperture is 100 mesh (that is, there are 100 mesh holes per inch length), which is suitable for scenes with finer material particle size requirements.

Screening of fine chemical raw materials

In the production of dyes, pigments, catalysts, etc., raw materials need to be graded according to particle size to ensure product quality. 100-mesh screen can effectively separate particles with a particle size of about 150 microns, and remove impurities or materials that do not meet the particle size requirements.

Regeneration and recovery of activated carbon

Vibrating slip screen is used for deashing and desludging of activated carbon. 100-mesh screen can intercept fine impurities and allow regenerated activated carbon to pass through, thereby improving recovery efficiency.

Production of food additives and seasonings

In the production of salt, sugar, spices, etc., 100-mesh screen can ensure uniform product particle size and prevent large particles from affecting taste or solubility. For example, it is used to remove lumps or foreign matter in milk powder production.

Feed raw material screening

In the production of fish meal, soybean meal and other feed raw materials, 100-mesh vibrating slip screen can remove impurities and lumps, ensure uniform feed particle size, and improve animal digestion and absorption rate.

100-mesh vibrating slip screen stands out from other vibrating screens due to its unique design and performance characteristics, designed for fine particle separation (approximately 150 microns) and processing of difficult materials.

-

Potato Starch Vibrating Screen

Granules, powders, and paddle materials can be used.

-

Screening black soldier fly feces and larvae can separate the worms and feces, saving labor.

-

Ensures removal of contaminants such as large particles and agglomerates from metal powders, providing accurate particle size distribution

-

Remove solids from liquid slurries and recover valuable materials in the waste stream for reuse.

-

Desert sand sieving machine

Desert sand sieving machine is a mechanical equipment used for sand and gravel processing or sieving...

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Vibrating screen for coal gangue screening

Z-type bucket elevator for peanut conveying is a vertical lifting equipment specially designed for fragile or soft conveying...

-

Filtering-Soya-Bean-Milk-screen

Filtering soya bean milk screen is a device specially used to separate soya milk from bean dregs. It filters out the solid residue...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.