Filtering Soya Bean Milk screen

Filtering soya bean milk screen is a device specially used to separate soya milk from bean dregs. It filters out the solid residue in the ground soya milk slurry through the pores of the screen to obtain clear and delicate soya milk. It is widely used in agriculture, food processing and other fields, and is a key tool to ensure taste, quality and efficiency in soy milk production. Its core is to intercept bean dregs particles through a screen with a specific aperture (expressed in mesh number) and allow liquid to pass through to achieve the purpose of purifying soy milk.

Video of filtering soya bean milk screen

What is the function of filtering soya bean milk screen?

The main function of filtering soya bean milk screen is to separate the solid residue (bean dregs) in the ground soy milk slurry from the liquid soy milk to ensure that the soy milk is delicate and free of impurities, including:

Improve taste: remove bean dregs particles to make the soy milk smoother, suitable for direct drinking or processing into soy products.

Improve purity: filtering soya bean milk screen can filter out impurities such as fiber and bean skin to ensure the food safety and appearance of soy milk.

Resource separation: Separate the bean dregs for subsequent use (such as feed, fertilizer or food processing).

Optimize the process: In automated production, the filtering soy bean milk screen reduces manual intervention and improves production results.

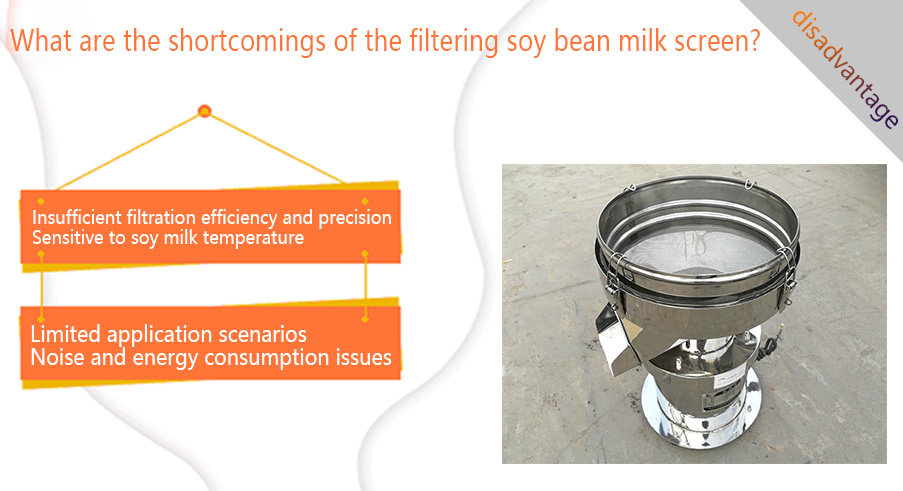

What are the shortcomings of the filtering soy bean milk screen?

Insufficient filtration efficiency and precision

Although high-mesh screens (such as above 200 mesh) can improve the fineness of soy milk, they are easy to cause the filtration speed to decrease and increase the processing time. For example, when a 200-mesh gauze screen is used for filtration in factory production, if the processing volume is large, it may affect the overall efficiency.

Sensitive to soy milk temperature

If the soy milk is hot filtered (such as above 80°C), the plastic seals or strips used in the filtering soy bean milk screen may deform and age; although the stainless steel material is heat-resistant, the screen tension may be affected by heat.

Limited application scenarios

It is inconvenient to use at home, inefficient and labor-intensive; although the electric filtering soy bean milk screen is convenient, it is large in size and takes up kitchen space. The production capacity of traditional filter screens is limited and it is difficult to cope with large-scale production. For example, in factory production, hundreds of liters of soy milk need to be processed every hour, and ordinary filtering soy milk screens may not be able to meet the needs of continuous operation.

Noise and energy consumption issues

It makes a lot of noise when working, which may affect the user experience; some models have high energy consumption, which increases the cost of use. With the use of automated equipment, it is necessary to manually monitor the filtering effect and clean up the residue in time, which makes it difficult to achieve complete unmanned operation.

Recommended mesh number of filtering soy bean milk screen

The mesh number selection of filtering soy bean milk screen directly affects the fineness, taste, production efficiency and dregs separation effect of soy milk. In soy milk production, the recommended mesh number needs to be comprehensively considered according to the specific purpose, raw material characteristics and production scale.

|

Mesh range |

Corresponding aperture (μm) |

Applicable scenarios |

Feature description |

|

60 mesh |

250μm |

Coarse filtration stage (preliminary filtration) |

Can quickly separate large particles of bean dregs, suitable for filtering after initial grinding |

|

80 mesh |

180μm |

Ordinary household or commercial primary filtration |

Can retain some bean fragrance, high filtration efficiency, low cost |

|

100 mesh |

150μm |

Fine filtration stage, smooth taste |

Can effectively intercept fine dregs, and make soy milk more delicate |

|

120 mesh |

125μm |

High-end soy milk or concentrated slurry fine filtration |

Very fine filtration, suitable for pursuing a silky taste |

|

Above 150 mesh |

<100 μm |

Ultrafine filtration, nutritious soy milk process |

Very little filtration dregs, but slow filtration speed, easy to block the net |

Application scenarios of filtering soy bean milk screen

Soy product processing plant: The factory uses a filtering soy bean milk screen, and the mesh size is adjusted according to demand (such as 180-250 mesh) to achieve efficient separation of bean dregs and soy milk. The equipment must meet the requirements of food-grade stainless steel to ensure hygiene and safety.

Plant protein extraction: In industrial production, soybean protein needs to be separated from filtered soy milk. Combined with centrifugal separation technology, it is used as a pretreatment equipment to remove most of the dregs and reduce the subsequent processing costs.

Utilization of dregs: The filtered dregs can be used as a by-product in fertilizer or feed production. In this scenario, the mesh size of the filtering soy bean milk screen needs to be adjusted according to the subsequent use to ensure that the dregs particle size meets the requirements.

Filtering soy bean milk screen is the core equipment in the soy milk filtration process. It uses screens with different mesh sizes to achieve efficient separation of soy milk and dregs to meet diverse needs. If you want to know a certain type of filter screen (such as the specific parameters of the filter screen) or its optimization solution for a specific scenario, you can contact us via email or official website.

-

Potato Starch Vibrating Screen

Granules, powders, and paddle materials can be used.

-

Screening black soldier fly feces and larvae can separate the worms and feces, saving labor.

-

Ensures removal of contaminants such as large particles and agglomerates from metal powders, providing accurate particle size distribution

-

Remove solids from liquid slurries and recover valuable materials in the waste stream for reuse.

-

Desert sand sieving machine

Desert sand sieving machine is a mechanical equipment used for sand and gravel processing or sieving...

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Vibrating screen for coal gangue screening

Z-type bucket elevator for peanut conveying is a vertical lifting equipment specially designed for fragile or soft conveying...

-

EVA Polymer Powder Sieving Machine

EVA polymer powder sieving machine is a device specially used for sieving ethylene-vinyl acetate copolymer...

-

Palm-Nut-Grading-Screen-Machine

Palm nut grading screen machine is a key equipment in palm oil processing production line. This equipment can grade the size of palm kernel, shell, pulp or nut, remove...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.