Z-type bucket elevator for peanut conveying

What is a Z-type bucket elevator for peanut conveying?

Z-type bucket elevator for peanut conveying is a vertical lifting equipment specially designed for fragile or soft conveying granular materials such as peanuts. Its unique Z-shaped structure allows for horizontal feeding, vertical lifting, and horizontal unloading, making it ideal for processes that require multiple points of feeding and unloading, and effectively reducing damage to peanuts during transportation.

What is the working principle of the Z-type bucket elevator for peanut conveying?

① Z-shaped design: The equipment is arranged in a "Z" shape, including a horizontal feeding section, a vertical lifting section, and a horizontal discharging section, suitable for achieving vertical and horizontal transportation of materials in a limited space.

② It consists of a hopper (usually made of food grade polypropylene or stainless steel), a chain or belt, a drive motor, and a frame.

③ Peanuts are fed into the hopper through a vibrating feeder or manual feeding, and the chain drives the hopper to lift the peanuts from low to high. After passing around the top, they are dumped into the discharge outlet.

Analysis of the core drawbacks of Z-type bucket elevator for peanut conveying

Peanuts with high moisture content are prone to clogging: If the moisture content of peanuts is greater than 8% (such as just harvested or not fully dried after cleaning), they are prone to adhere to the hopper and shell, leading to a decrease in conveying efficiency or even clogging.

Thin shell varieties have a high damage rate: Thin shell peanuts such as Baisha and Luhua are prone to shell breakage (with a damage rate of up to 3% -5%) due to inertial impact during the flipping and unloading of the hopper.

Large impurities need to be pre treated: If there are stones, soil blocks, etc. with a diameter greater than 30mm mixed in the raw material, it may get stuck in the chain or damage the hopper.

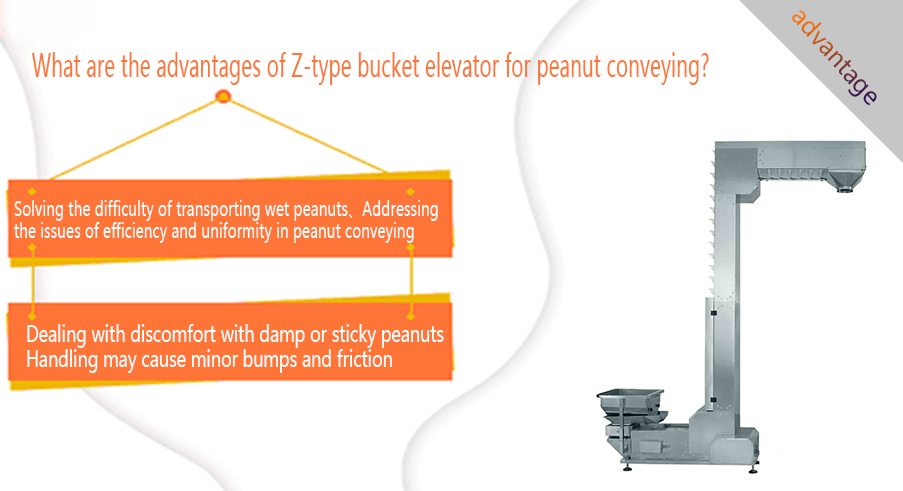

What are the advantages of Z-type bucket elevator for peanut conveying?

1. Solving the difficulty of transporting wet peanuts: Peanuts that have just been harvested or cleaned have a high moisture content and are prone to sticking into clumps or adhering to the hopper. The front or rear end of the Z-type bucket elevator for peanut conveying is equipped with drying, cleaning and other equipment to improve the condition of peanuts.

2. Addressing the issues of efficiency and uniformity in peanut conveying: The Z-shaped structure of the peanut conveying Z-bucket elevator allows for multiple feed and discharge ports to be set up at different levels, facilitating the connection of different production stages and optimizing the process flow.

3. Dealing with discomfort with damp or sticky peanuts: Peanuts with high moisture content or slight stickiness on the surface may adhere to the inner wall of the hopper. The hopper design of peanut conveying Z-type bucket elevators is usually optimized for specific size ranges.

4. Handling may cause minor bumps and friction: Peanuts may still experience minor bumps and friction during loading, lifting, and unloading processes. The transition between the horizontal and vertical segments of the Z-shaped structure is usually designed to be relatively smooth to avoid severe compression of the peanut during turning.

Technical parameters of Z-type bucket elevator for peanut conveying

|

Parameter category |

Technical indicators |

Optional range |

Remarks |

|

Conveying capacity |

2-20 t/h |

1-50 t/h (customizable) |

Depending on peanut variety (with/without shell) |

|

Elevate the height |

3-15m |

with a maximum of 30m (specially customized) |

and strengthen the support structure for every 5m increase |

|

Horizontal segment length |

2-10 m |

maximum 15 m |

angled at 60 ° -80 ° with vertical segment |

|

Running speed |

0.8-1.2 m/s |

0.5-1.5 m/s (adjustable) |

Recommended for shelled peanuts ≤ 1.0 m/s |

Application of Z-type bucket elevator for peanut conveying

1. Peanut cleaning and processing process: In the peanut cleaning process, peanuts usually need to be transported from the ground or warehouse to the cleaning equipment. The peanut conveying Z-type bucket elevator can lift peanuts from low to high, achieving automated conveying.

2. Peanut peeling and screening process: Peanuts need to undergo multiple screenings and sorting during the peeling process. The Z-shaped bucket elevator is often used to transport cleaned peanuts to the peeling equipment or screening machine, ensuring smooth flow of peanuts during processing.

3. Peanut packaging and storage: The Z-type bucket elevator for peanut conveying can be used to transport peanuts from a certain part of the production line to the packaging machine, package them into bags or boxes, and facilitate subsequent storage or transportation.

4. The production line of a large peanut processing plant: The Z-type bucket elevator for peanut conveying is widely used in material conveying at various stages. For example, transporting peanuts from the raw material warehouse to the initial processing equipment, from the cleaning equipment to the drying equipment, greatly improves the automation level of the production line.

Selection precautions for Z-type bucket elevator for peanut conveying

Small peanut processing (2-3 tons/hour): Choose models with a lifting height of 3-5 meters, hopper capacity of 1-2 liters, and power of 0.75-1.5 kW.

Large peanut production line (5-10 tons/hour): Choose models with a lifting height of 6-10 meters, hopper capacity of 4-6 liters, and power of 2-3kW.

Z-type bucket elevator for peanut conveying plays an important role in the processing, cleaning, peeling, screening, and packaging of peanuts, especially in large-scale and automated production. Its high efficiency, stability, and space saving characteristics make it an indispensable equipment for peanut processing enterprises.

-

Potato Starch Vibrating Screen

Granules, powders, and paddle materials can be used.

-

Screening black soldier fly feces and larvae can separate the worms and feces, saving labor.

-

Ensures removal of contaminants such as large particles and agglomerates from metal powders, providing accurate particle size distribution

-

Remove solids from liquid slurries and recover valuable materials in the waste stream for reuse.

-

Plastic granules square swing screen

Plastic granules square swing screen is a device specially used for screening plastic granules. It is suitable for...

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Nylon sieve

Nylon sieve is a common screening tool, widely used in laboratories and industrial production, mainly...

-

Drying sand vibrating screen

Drying sand vibrating screen is a vibrating screening device specially used for screening dried sand. It...

-

Vibrating screen for coal gangue screening

Vibrating screen for coal gangue screening is a kind of equipment specially used for grading and...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.