desert sand sieving machine

Desert sand sieving machine is a mechanical equipment used for sand and gravel processing or sieving in desert areas, usually related to sand control, desert management or construction sand processing. It is a mechanical equipment used to screen desert sand, which can efficiently separate fine sand, coarse sand and impurities, improve the quality and utilization value of sand, and is also used for specific purposes, such as ecological restoration, construction material preparation or sand industry development.

Main functions of desert sand sieving machine

①Screening sand: Separate stones, debris, etc. mixed in the sand to get clean sand.

②Improve efficiency: Automated operation reduces the time and labor cost of manual sand sieving.

③Adapt to harsh environment: Can work stably in harsh environments such as deserts and has strong durability.

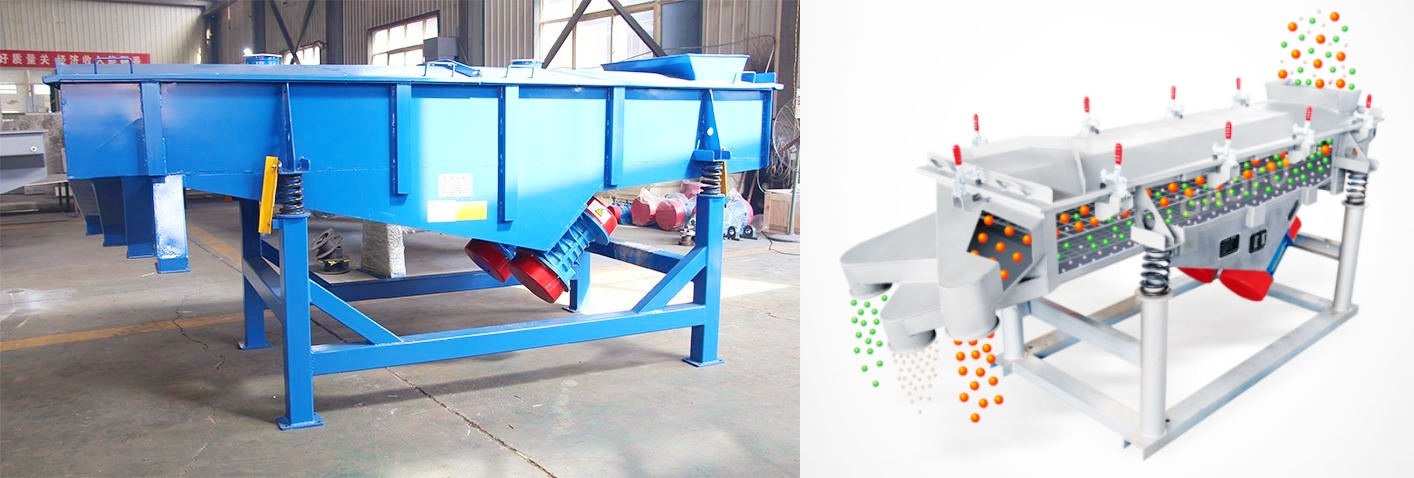

How does a desert sand sieving machine work?

Desert sand sieving machines usually use vibrating sieving machines or drum screens to separate impurities from sand through screens of different sizes. Some advanced sand sieving machines are also equipped with a water washing function to further remove salt and other soluble impurities from the sand.

What types of desert sand sieving machines are there?

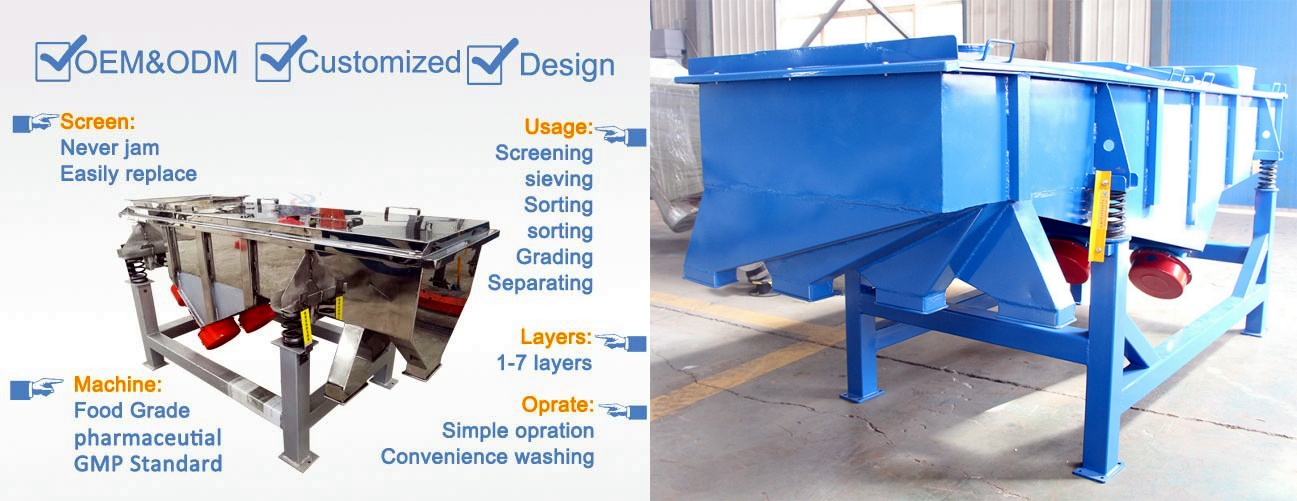

1. sand sieving machine

Simple structure, stable operation, large processing capacity

Suitable for processing large amounts of desert sand, often used in large sand fields, mines and other places.

2.Vibrating screen sand sieving machine

High sieving accuracy, quickly and effectively separates desert sand of different particle sizes

Widely used in industrial production with high sieving accuracy requirements.

3.Swing Screen Sand Sieving Machines

The low-frequency rotary vibrating screen that simulates manual sieving can manually control the movement trajectory and retention time of materials on the screen surface. It has advantages when processing desert sand that is easy to clog the screen and requires fine sieving.

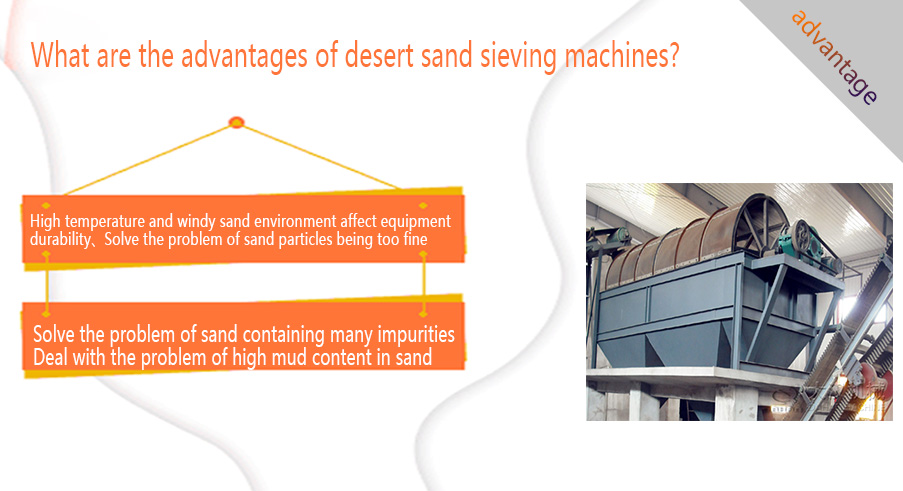

What are the advantages of desert sand sieving machines?

1. High temperature and windy sand environment affect equipment durability: The desert environment is hot and dry, which causes the sand sieving machine parts to age easily and wear quickly. Use heat-resistant and wear-resistant materials to manufacture key components such as screens and bearings, and install sealing covers to prevent wind and sand from entering.

2. Solve the problem of sand particles being too fine: The weathered sand particles in the desert are usually fine and easy to clog the screen. Through the desert sand sieving machine, combined with multi-layer screens with different mesh sizes, sand of different particle sizes can be gradually screened.

3. Solve the problem of sand containing many impurities: The sand in the desert may contain a large amount of impurities such as shells, stones, and plant residues. The drum screen can effectively separate large impurities, and the magnetic separation device can remove metal impurities to ensure the purity of the sand.

4. Deal with the problem of high mud content in sand: Some desert sand sieving machines are equipped with pre-washing devices to wash the sand before sieving. Through the flushing effect of water flow, the blockage of the screen by the soil and the impact on the sieving effect during the subsequent sieving process are reduced.

Application of Desert Sand Sieving Machines

Construction Engineering: Ordinary desert weathered sand often does not meet the standards for concrete sand. The screened sand can be used in the preparation of building materials such as concrete and mortar.

Road Construction: The native sand in the desert contains a lot of impurities, and direct use will affect the stability of the roadbed. Desert sand sieving machine can separate fine sand and coarse sand, optimize the ratio of the mixture, and enhance the strength and durability of the highway foundation.

Land Improvement: The governance of desertified areas requires soil transformation and improving land utilization. The sand screened by the desert sand sieving machine can be used to improve saline-alkali land or other land restoration work.

Construction of solar and wind energy projects: Desert sand sieving machine can provide suitable sand and gravel for the foundation of wind turbines to improve the stability of the foundation.

Precautions for desert sand sieving machines

1. Equipment maintenance: Regularly check key components such as screens and vibration devices to ensure the normal operation of the equipment.

2. Power selection: In desert areas without electricity supply, it is more appropriate to choose a diesel-driven sand sieving machine.

3. Environmental adaptability: Choose equipment suitable for the desert environment to ensure that it can work for a long time under high temperature and dusty conditions.

Desert sand sieving machines need to take into account efficiency, durability and environmental protection, and their design needs to be optimized for the characteristics of high temperature, wind and sand, and lack of resources in the desert.

-

Potato Starch Vibrating Screen

Granules, powders, and paddle materials can be used.

-

Screening black soldier fly feces and larvae can separate the worms and feces, saving labor.

-

Ensures removal of contaminants such as large particles and agglomerates from metal powders, providing accurate particle size distribution

-

Remove solids from liquid slurries and recover valuable materials in the waste stream for reuse.

-

Concrete batching fpr sieving machine

Concrete batching fpr sieving machine is a kind of equipment used to screen and batch raw materials...

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Nylon sieve

Nylon sieve is a common screening tool, widely used in laboratories and industrial production, mainly...

-

Drying sand vibrating screen

Drying sand vibrating screen is a vibrating screening device specially used for screening dried sand. It...

-

Vibrating screen for coal gangue screening

Vibrating screen for coal gangue screening is a kind of equipment specially used for grading and...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.