Chicken essence vibrating screen

Chicken essence vibrating screen is a screening device specially designed for chicken essence or other powdered and granular materials. It is mainly used for particle size classification, impurity removal and product quality control in the production process of chicken essence. Due to the special properties of chicken essence, such as easy moisture absorption and agglomeration, chicken essence vibrating screen has specific requirements in design and material selection. It classifies the material according to particle size through vibration to ensure the uniformity and quality of the product.

Video of chicken essence vibrating screen

What is the function of chicken essence vibrating screen?

1、Screening: Screening is one of the main functions of the chicken essence vibrating screen. Through the vibrating screening equipment, the chicken essence particles can be separated into different particle groups according to their size, thereby realizing the screening and separation of the chicken essence particles. This helps to remove unwanted fine particles or impurities and improve the purity and quality of the product.

2、Impurity removal: Impurity removal refers to the removal of impurities or foreign matter in the chicken essence during the screening process. Through the action of the vibrating screen, the chicken essence vibrating screen can effectively separate impurities from the chicken essence particles to ensure the cleanliness and purity of the product. This helps to improve the quality and hygiene standards of chicken essence products.

3、Grading: Grading refers to the classification of chicken essence particles into different grades or categories according to their size or other characteristics. In the production of chicken essence, the vibrating screen can adjust the vibration parameters and screen specifications as needed to achieve accurate grading of chicken essence particles and ensure that the product meets specific specification requirements.

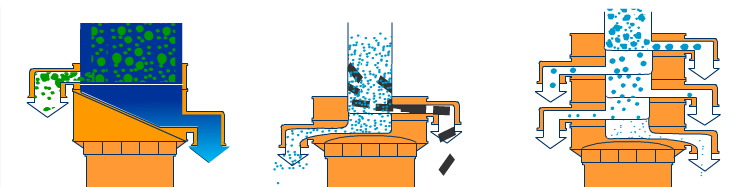

how does the chicken essence vibrating screen work?

The working principle of chicken essence vibrating screen is similar to that of other vibrating screens. It uses the exciting force generated by the vibration motor to make the chicken essence particles on the screen surface move in three dimensions on the screen, thereby achieving the separation of particles of different particle sizes.

Features of Chicken Essence Vibrating Screen

1. Fully enclosed design: Chicken essence is easy to absorb moisture, and the fully enclosed design can effectively prevent the chicken essence from getting damp and agglomerating, ensuring the screening effect.

2. Sanitary material: All parts in contact with chicken essence are made of food-grade stainless steel, which meets food hygiene standards.

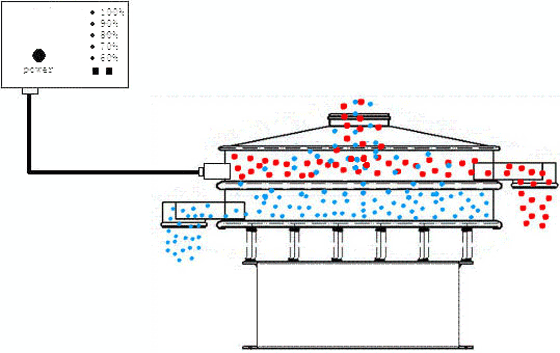

3. Multi-layer screen: Multiple layers of screens with different apertures can be configured as needed to achieve multi-level screening.

4. Screen cleaning device: Equipped with a bouncing ball or ultrasonic screen cleaning device to effectively prevent the screen from being blocked.

5. Easy to disassemble design: Convenient for cleaning and maintenance to ensure production hygiene.

The structure of chicken essence vibrating screen

Screen Frame: The screen frame is the main structure that supports the screen mesh and other components of the vibrating screen. It provides the necessary rigidity and support for the entire system.

Screen Mesh: The screen mesh is the surface on which the chicken essence particles are sieved. It is made of woven wire, perforated plates, or other materials with specific opening sizes to allow particles of certain sizes to pass through while retaining larger particles.

Vibration Motor: The vibration motor is responsible for providing the necessary vibration to the screen frame. It generates the vibratory motion that helps in the sieving process by moving the particles across the screen mesh.

Supporting Springs: Supporting springs are used to connect the screen frame to the base of the vibrating screen. These springs help in absorbing the vibration generated by the motor, reducing noise and impact on the surrounding environment.

Feed Inlet and Outlet: The feed inlet allows the chicken essence mixture to enter the vibrating screen for sieving, while the outlet collects the sieved particles based on their size for further processing or packaging.

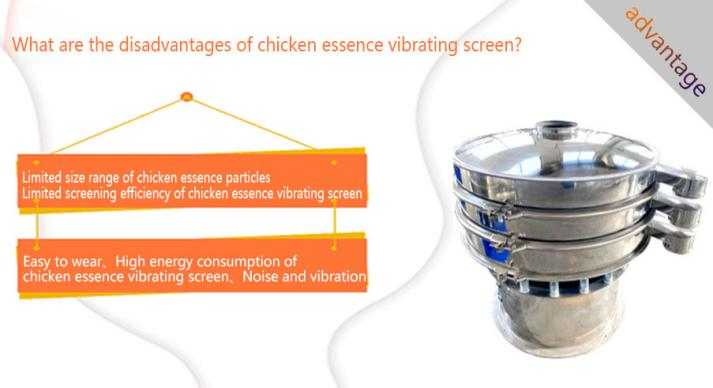

What are the disadvantages of chicken essence vibrating screen?

1. Limited size range of chicken essence particles: Chicken essence particles of different specifications may require screens of different specifications, so the size range of chicken essence vibrating screen may be limited to a certain extent, and it is necessary to select appropriate equipment according to actual conditions.

2. Limited screening efficiency of chicken essence vibrating screen: For some chicken essence particles with special shapes or easy to stick together, the screening efficiency of chicken essence vibrating screen may be limited, and additional measures need to be taken to solve these problems.

3. Easy to wear: Since the chicken essence vibrating screen will be subject to friction and impact of particles during long-term operation, parts such as the screen are prone to wear and need to be replaced and maintained regularly, increasing maintenance costs and workload.

4. High energy consumption of chicken essence vibrating screen: Chicken essence vibrating screen usually needs to use equipment such as vibration motors to provide power, which may lead to a certain degree of high energy consumption and increase production costs.

5. Noise and vibration: The chicken essence vibrating screen will generate certain noise and vibration when working, which may have a certain impact on the working environment and operators at the production site.

What are chicken essence vibrating screens used for?

1. Large chicken powder production line: Before the chicken powder enters the production line, a chicken powder vibrating screen is used for preliminary screening to remove large impurities; after the mixing process, a multi-layer chicken powder vibrating screen is used for multi-level grading to ensure uniform product particle size; before packaging, a high-precision chicken powder vibrating screen is used for the final screening to ensure product quality.

2. Small chicken powder processing plant: A multifunctional chicken powder vibrating screen is used, which can be used for both raw material screening and finished product grading to improve production efficiency.

3. Food R&D laboratory: A small chicken powder vibrating screen is used to analyze the particle size of chicken powders with different formulas to provide data support for product development.

How to fix a chicken essence vibrating screen?

Check the fault phenomenon: First, you need to carefully observe the fault phenomenon of the vibrating screen, such as whether there is abnormal noise, unstable vibration, poor screening effect, etc., to determine the specific problem that needs to be repaired.

Power off and safety: Before performing any maintenance work, be sure to disconnect power supply of vibrating screen and ensure that equipment is in a safe state to avoid accidental injury.

Cleaning and maintenance: Regular cleaning and maintenance of the vibrating screen is very important to reduce the possibility of failure. Clear the blockage on the screen, clean the vibration motor and check the support spring and other components.

Check the motor and transmission system: Check whether the vibration motor, belt drive system and other components are working properly to ensure that the motor is running normally and the transmission efficiency is high.

Chicken essence vibrating screen manufacturers

Chicken essence vibrating screen is an indispensable equipment in the production process of chicken essence. It improves product quality and production efficiency through vibration screening and is widely used in many industries. Through correct selection and maintenance, production efficiency and product quality can be effectively improved.

-

Fully sealed structure, no powder overflow, no liquid overflow

-

Remove lumps and debris in flour, improve flour quality

-

For safe sieving and precise grading of liquids, powders and granules, suitable for plants and factories that need to handle large volumes of products

-

For separation of different particle sizes in the same product, safe screening to eliminate foreign matter, solid-liquid separation, etc.

-

Chemical catalyst vibrating screen

Chemical catalyst vibrating screen is a device specially used for screening and grading chemical catalyst...

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Standard test sieve

Standard test sieves are precision mesh screens used to separate particles based on size in various industries ...

-

Circular swing screen

Circular swing screen, also known as swing screen or shaking screen, is a low-frequency rotary vibration...

-

Three-dimensional rotary vibrating screen

Three-dimensional rotary vibrating screen, also known as the rotary vibrating screen or the three-dimensional...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.