Circular swing screen

Circular swing screen, also known as swing screen or shaking screen, is a low-frequency rotary vibration screening equipment that imitates manual shaking screening. It is mainly used for efficient and high-precision screening of materials in granular, strip, block, and even irregular shapes. It achieves material screening and grading through unique swinging motion, with high screening accuracy, large processing capacity, and low noise. Circular swinging screens are widely used in industries such as food, medicine, chemical, and metallurgy.

Video of circular swing screen

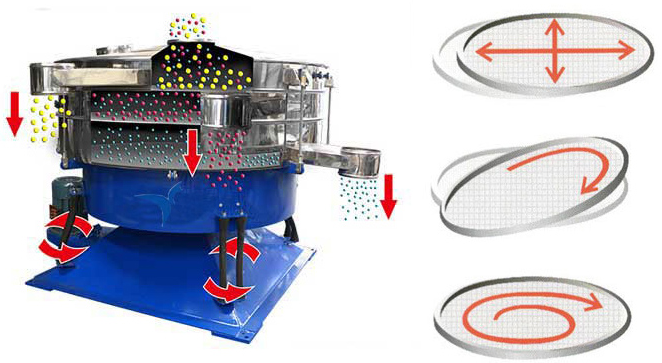

How does the circular swing screen work

1. Movement mode: The circular swing screen adopts three-dimensional swing motion (horizontal, vertical, inclined) to generate spiral motion of the material on the screen surface. This movement method can improve screening efficiency and prevent screen clogging.

2. Screening process: The material enters from the top of the screening machine, and under the action of swinging motion, fine particles pass through the screen mesh, while coarse particles move along the screen surface and are discharged from the discharge port.

What is the use of circular swing screen?

Circular swing screens are widely used in laboratory particle analysis, particle distribution research, particle screening, and other fields. It has important application value in materials science, food processing, pharmaceutical industry, chemical industry and other fields. By using a circular swing sieve, particle analysis of samples can be performed quickly and accurately, providing important data support for scientific research and production.

What are the advantages of a circular swing screen?

1. Efficient material conveying: The swinging motion of the circular swing screen can quickly and evenly disperse and flow materials on the screen surface, avoiding material blockage and accumulation, thus achieving continuous and efficient screening operations. It can process a large amount of materials in a unit time and improve production efficiency.

2. Large diameter screen surface: usually has a larger screen surface diameter, providing a wider screening space for materials, increasing the contact area between materials and the screen mesh, allowing more materials to be screened simultaneously, thereby improving the overall processing capacity and suitable for material screening in large-scale production.

3. Multiple material adaptability: Whether it is granular, powdered, or sheet-like materials, the circular swing screen can effectively screen them. For materials with different properties, such as moisture, viscosity, and poor flowability, by adjusting parameters such as swing frequency and amplitude, good screening effects can also be achieved. It is widely used in various industries such as food, chemical, pharmaceutical, and mining.

4. Customizable: It can be customized according to different production needs, such as screen material, screen surface diameter, number of layers, processing capacity, etc., to meet the requirements of various special materials and production processes, and provide personalized screening solutions for users.

5. Multi angle motion: The circular swing screen uses a unique swing motion method to make the material move in a complex elliptical trajectory on the screen surface. This motion method allows the material to more fully contact the screen mesh, reducing the sliding and stacking of the material on the screen surface, thereby improving the screening accuracy. The material can be accurately classified according to different particle sizes, and particles with small differences in particle size can be effectively separated.

The structure of circular swing screen

Screen Frame: The screen frame is the main structure of the circular swing screen, providing support for other components and holding the screen mesh in place.

Screen Mesh: The screen mesh is the surface on which the material is sieved. It is typically made of metal wire or synthetic material with specific mesh sizes to allow particles of certain sizes to pass through.

Vibration Motor: The vibration motor is responsible for providing the necessary vibration to the screen frame. This vibration helps in the movement and separation of particles on the screen mesh.

Screen Box: The screen box houses the screen frame and screen mesh. It is designed to contain the material being sieved and prevent spillage.

Exciter: The exciter is a component that generates the vibration in the screen frame. It typically consists of an eccentric shaft with unbalanced weights that create the necessary vibration.

Supporting Springs: Supporting springs are used to connect the screen frame to the base or supporting structure. These springs help in absorbing the dynamic forces generated during the screening process.

Drive Unit: The drive unit is responsible for providing power to the vibration motor and controlling the speed and intensity of the vibration.

Control Panel: In some models, a control panel is included to allow operators to adjust the vibration parameters, such as amplitude and frequency, as well as monitor the screening process.

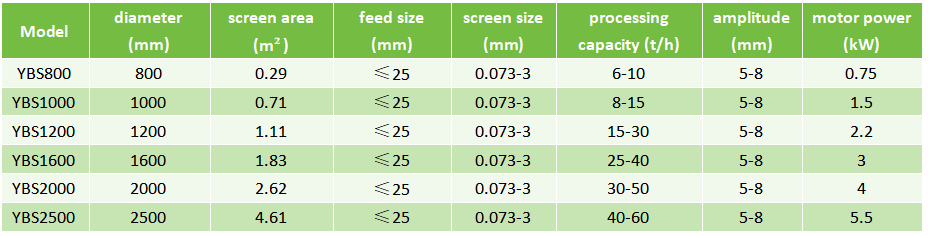

Technical parameters of circular swing screen

What can a circular swing screen be used for?

1. Food industry: Circular swing screens are used to screen the ground flour, remove impurities, and grade the flour according to different degrees of fineness to meet the needs of making different noodle products. For some seasonings, a circular shaking sieve can remove clumps or oversized particles, ensuring particle uniformity, and also facilitating product packaging and measurement.

2. Chemical industry: After extrusion granulation, plastic particles are sieved through a circular swing screen to classify plastic particles of different sizes, meeting the requirements of different plastic product production for plastic particle size. Sieve pigment and dye powders to ensure uniform particle size, improve the coloring effect and stability of pigments and dyes, and enable products to play a role in coatings and other fields.

3. Mining industry: Circular swing screens are used to grade crushed ores, separating ore particles of different sizes for subsequent beneficiation processes. For mining products such as quartz sand, quartz sand can be classified into different grades according to particle size based on different uses and market demands, and used in fields such as glass manufacturing and building materials.

4. Metallurgical industry: Circular swing screens are used to screen the metal powders, control the particle size distribution of the metal powders, and meet the strict requirements of powder metallurgy, 3D printing and other processes for the particle size of metal powders. In the production of refractory materials, it is necessary to ensure that the particle size distribution of refractory materials is reasonable and meets the requirements for the use of high-temperature furnaces and other equipment in the metallurgical industry.

Daily maintenance of circular swing screen

Regular cleaning: Regularly clean the sieve and equipment to maintain cleanliness.

Check fasteners: Regularly check whether the connections of each component are tight, and tighten them in a timely manner if they are loose.

Lubrication: Regularly add lubricating oil to components such as bearings that require lubrication.

Check vulnerable parts: Regularly inspect vulnerable parts such as screens and springs, and replace them promptly if damaged.

Circular swing screens have significant advantages in multiple aspects and are suitable for various industrial applications.

-

Fully sealed structure, no powder overflow, no liquid overflow

-

Remove lumps and debris in flour, improve flour quality

-

For safe sieving and precise grading of liquids, powders and granules, suitable for plants and factories that need to handle large volumes of products

-

For separation of different particle sizes in the same product, safe screening to eliminate foreign matter, solid-liquid separation, etc.

-

Chemical catalyst vibrating screen

Chemical catalyst vibrating screen is a device specially used for screening and grading chemical catalyst...

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Standard test sieve

Standard test sieves are precision mesh screens used to separate particles based on size in various industries ...

-

Washing powder vibrating screen

Washing powder vibrating screen is a device specially used for screening and removing impurities from washing powder...

-

Sewage impurity removal vibrating screen

Sewage impurity removal vibrating screen is a device specially used to remove solid impurities in the sewage...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.