Washing powder vibrating screen

Washing powder vibrating screen is a device specially used for screening and removing impurities from washing powder. It is mainly used to classify washing powder according to particle size to ensure product uniformity. The vibrating screen uses the high-frequency vibration generated by the vibration motor to make the washing powder move on the screen, thereby achieving the screening effect. It can effectively remove impurities and lumps in the washing powder to ensure the purity and quality of the washing powder. The washing powder vibrating screen plays an important role in the production process of washing powder.

Video of washing powder vibrating screen

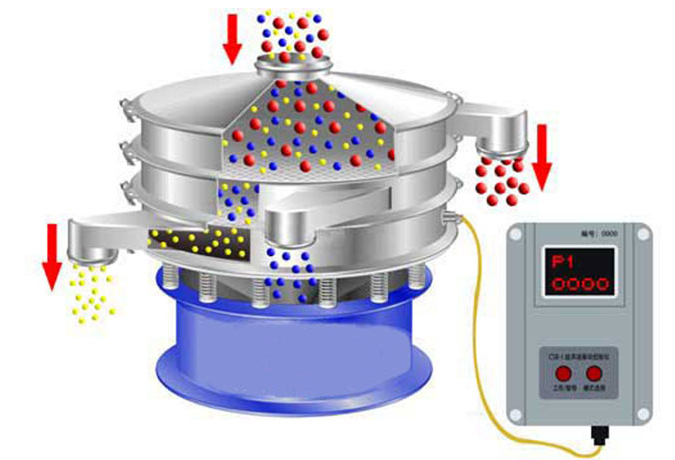

How does the washing powder vibrating screen work?

The working principle of washing powder vibrating screen is to use the vibration generated by the vibration motor to make the screen box resonate, so that the material on the screen surface jumps on the screen surface and moves forward. The apertures on the screen are different. During the movement of the material, the material larger than the screen hole is retained on the screen surface, and the material smaller than the screen hole passes through the screen and falls into the next layer or the discharge port, thereby realizing the classification of the material.

Features of washing powder vibrating screen

High-efficiency screening: driven by a vibrating motor, the screening efficiency is high and suitable for mass production.

Multi-layer screen design: multiple layers of screens can be configured according to needs, and washing powders of different particle sizes can be screened out at the same time.

Anti-clogging design: a bouncing ball or ultrasonic screen cleaning device is used to prevent the screen from clogging.

Durable material: the part in contact with the material is usually made of stainless steel, which is corrosion-resistant and easy to clean.

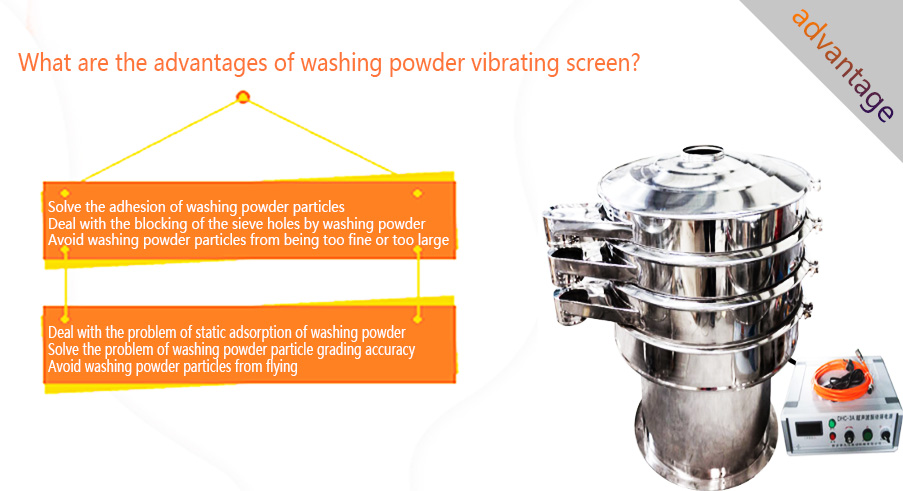

What are the advantages of washing powder vibrating screen?

1. Solve the adhesion of washing powder particles: Washing powder vibrating screen can effectively reduce the adhesion between particles through vibration, help the particles flow freely on the screen, and make the particles less likely to stick together during the screening process, so as to maintain the independence of the particles.

2. Deal with the blocking of the sieve holes by washing powder: The vibration of washing powder vibrating screen can prevent the sieve holes from being blocked by particles, help the particles pass through the sieve smoothly, and effectively prevent the particles from accumulating in the sieve holes, reduce the possibility of sieve hole blocking, and maintain the screening efficiency.

3. Avoid washing powder particles from being too fine or too large: By selecting sieves of different specifications and apertures, adjust the screening particle size of the vibrating screen as needed to avoid the problem of too fine or too large particles. Select the appropriate sieve according to product requirements and particle characteristics to achieve accurate particle classification and ensure product quality.

4. Deal with the problem of static adsorption of washing powder: Washing powder particles are prone to static electricity during the screening process, causing the particles to be adsorbed on the sieve or the inner wall of the equipment. Use anti-static materials to make the sieve and the inner wall of the equipment to reduce static electricity. Ground the equipment to export static electricity and avoid particle adsorption.

5. Solve the problem of washing powder particle grading accuracy: washing powder needs to be accurately graded according to particle size to meet the needs of different products. The washing powder vibrating screen can be equipped with multiple layers of screens (such as 20 mesh, 40 mesh, 60 mesh, etc.) to achieve multi-level screening at the same time. By adjusting the vibration frequency and amplitude, the movement trajectory of the particles on the screen is controlled to improve the screening accuracy.

6. Avoid washing powder particles from flying: washing powder particles are small, and dust is easily generated during the screening process, which not only causes material waste, but also may affect the working environment and the health of operators. The washing powder vibrating screen adopts a fully enclosed structure to prevent dust from spilling out. A negative pressure environment is formed during the screening process to further control the spread of dust.

What can the washing powder vibrating screen be used for?

1. Washing powder production line: The washing powder vibrating screen is usually set after the mixing and granulation processes to remove oversized particles, incompletely mixed materials and generated dust. Before the washing powder is packaged, the washing powder is finally screened to ensure product quality and prevent large particles or impurities from entering the packaging bag.

2. Quality control before packaging: Before the washing powder is packaged, the finished product is finally screened using a vibrating screen to ensure that the washing powder particles in the packaging bag meet the standards. Through screening, the particle size distribution of the washing powder can be controlled to ensure the uniformity and fluidity of the product.

3. Treatment of rework materials: During the production process, some unqualified washing powder (such as oversized particles or agglomerates) may be produced. These rework materials can be re-screened through the vibrating screen and recycled. Washing powder can be divided into different grades according to different particle size requirements to meet the needs of different customers.

4. Application in R&D laboratories: In detergent R&D laboratories, washing powder vibrating screens can be used to analyze the particle characteristics of washing powders with different formulas to help optimize product formulas. Researchers can use vibrating screens to analyze the particle characteristics of new washing powders, evaluate product performance, and guide the development and improvement of new products.

5. Environmental science research: In the sewage treatment process, washing powder vibrating screens can be used to screen and grade washing powder and other detergent residues to help purify water quality. They can also be used to treat washing powder waste to achieve resource reuse or reduce the impact on the environment.

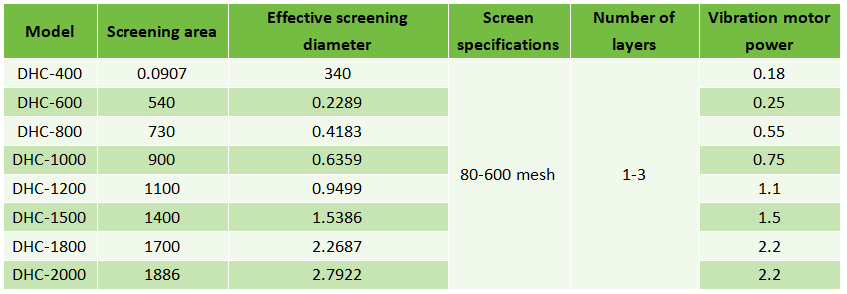

Technical parameters of washing powder vibrating screen

How to repair the washing powder vibrating screen?

1. Safety measures: Before performing any maintenance work, always disconnect the power supply to ensure that the equipment is in a safe state. Wear appropriate personal protective equipment, such as gloves, goggles, etc., to avoid accidental injuries.

2. Check the problem: First, determine the specific problem of the washing powder vibrating screen, which may be the failure of the equipment to start, unstable vibration, damaged screen, etc. Check the various components of the equipment, including the motor, vibrator, screen, etc., to see if there is any obvious damage or malfunction.

3. Cleaning and maintenance: Clean the vibrating screen and its surrounding areas regularly to ensure that there is no accumulated dust, particles or other debris that affects the normal operation of the equipment. Check whether the screen is clean, remove clogged particles, and ensure that the screen is unobstructed.

4. Replace damaged parts: If some parts of the equipment are found to be damaged, they need to be replaced in time. For example, if the screen is broken or damaged, a new screen needs to be replaced. Make sure to choose replacement parts that are suitable for the equipment model to avoid problems caused by mismatch.

5. Adjustment and calibration: After replacing parts, it may be necessary to readjust and calibrate the equipment to ensure the normal operation and screening effect of the vibrating screen. Adjust and calibrate according to the equipment's instruction manual or the guidance provided by the manufacturer.

Washing powder vibrating screen plays an important role in the production process of washing powder. Through screening, impurities can be effectively removed and the quality of washing powder can be improved. When choosing a washing powder vibrating screen, you should choose the appropriate equipment according to the characteristics of the washing powder and production requirements.

-

Fully sealed structure, no powder overflow, no liquid overflow

-

Remove lumps and debris in flour, improve flour quality

-

For safe sieving and precise grading of liquids, powders and granules, suitable for plants and factories that need to handle large volumes of products

-

For separation of different particle sizes in the same product, safe screening to eliminate foreign matter, solid-liquid separation, etc.

-

Chemical catalyst vibrating screen

Chemical catalyst vibrating screen is a device specially used for screening and grading chemical catalyst...

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Standard test sieve

Standard test sieves are precision mesh screens used to separate particles based on size in various industries ...

-

Standard test sieve

Foam particle straight screen is a special device for screening foam particles. It is mainly used to classify...

-

Flour swing screen

Flour swing screen is a vibrating screen specially used for sieving flour. Through the vibration of the screen...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.