Glaze vibrating sieve

Glaze vibrating sieve is a device specially used for screening glazes, which is widely used in ceramics, building materials, chemical industry and other industries. Glazes are usually mixed with various powders and particles, and the sieving process requires high precision and efficiency of the equipment. Glaze vibrating sieve separates impurities and particles in glaze by vibration, realizes efficient screening and grading of glaze, and ensures the uniformity and quality of the glaze.

Video of the glaze vibrating sieve

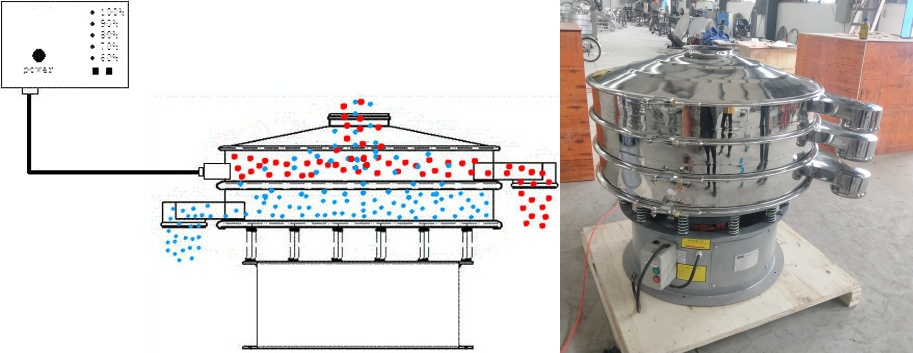

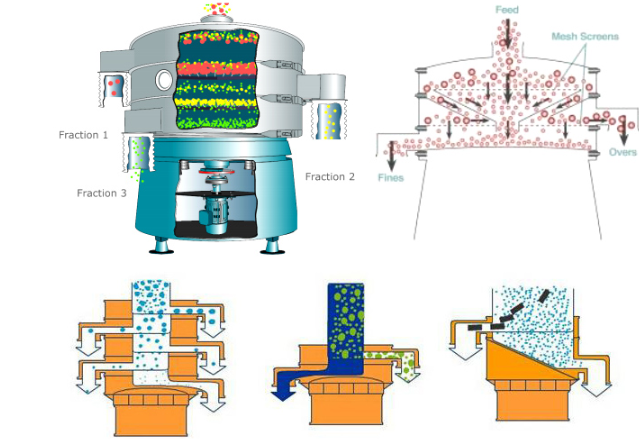

How does the glaze vibrating sieve work?

Glaze vibrating sieve uses the exciting force generated by the vibration motor to make the glaze slurry on the sieve surface jump in the vertical direction and throw in the horizontal direction. Particles smaller than the screen aperture pass through the screen and fall into the discharge port below, while particles larger than the sieve aperture are retained on the sieve surface and discharged from another discharge port.

What does a glaze vibrating sieve do?

1.Remove impurities: During the production process of glaze, some impurities may be mixed in, such as unground raw material particles, dust, metal chips, etc. These impurities will affect the quality and stability of the glaze and cause defects on the glaze surface. Glaze vibrating sieve can effectively remove these impurities and ensure the purity of the glaze.

2. Control the particle size: The particle size of the glaze has a great influence on the effect of the glaze. Too coarse particles will cause the glaze surface to be rough, and too fine particles will cause the glaze surface to have poor fluidity. Glaze vibrating sievecan select screens with different apertures as needed to achieve precise control of the glaze particle size and ensure the smoothness and uniformity of the glaze surface.

3. Improve the uniformity of the glaze: The glaze is a mixture of multiple mineral raw materials. If the mixture is not uniform, it will cause color difference or inconsistent texture on the glaze surface. During the screening process, glaze vibrating sieve can fully mix the glaze slurry and improve the uniformity of the glaze.

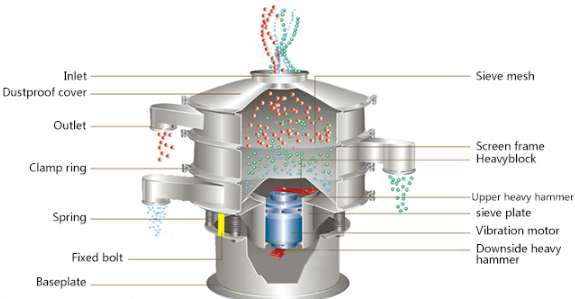

Structure of glaze vibrating sieve

Glaze vibrating sieve consists of a sieve box, sieve mesh, vibration motor, base and spring, as well as seals, feed port and discharge port. The sieve box is usually made of stainless steel and is used to carry the sieve mesh and glaze. The sieve mesh can be installed in a single layer or multiple layers. Different materials (such as stainless steel, nylon) and mesh sizes can be selected according to the characteristics of the glaze to achieve multi-level screening.

What are the disadvantages of glaze vibrating sieve?

1. High energy consumption and equipment maintenance cost: Glaze vibrating sieve usually requires electricity or other energy to drive, so it may consume more energy, resulting in higher energy consumption costs. As a mechanical equipment, glaze vibrating screen requires regular maintenance and upkeep, including cleaning, lubrication and parts replacement, which may increase the operating costs of the enterprise.

2. Limited screening accuracy: The screening accuracy of the vibrating sieve is limited by the mesh aperture and vibration parameters, and may not fully meet certain application scenarios that require high-precision screening.

3. Not suitable for all materials: Some granular materials with special properties may not be suitable for screening through glaze vibrating screens, and other more suitable screening equipment is required.

4. High noise and easy to clog: Glaze vibrating screens will generate noise and vibration during operation, which may cause a certain degree of interference and discomfort to the working environment and employees. Glaze vibrating screens may be clogged and need to be cleaned and maintained regularly, affecting production efficiency.

What is glaze vibrating sieve used for?

Glaze vibrating sieve is mainly used for removing impurities or grading glaze in the ceramic industry. It can effectively remove impurities and foreign matter in the glaze, ensure the purity and particle size uniformity of the glaze, and improve the quality of the glaze. It can also be used for screening and filtering similar materials in the chemical, food, pharmaceutical and other industries.

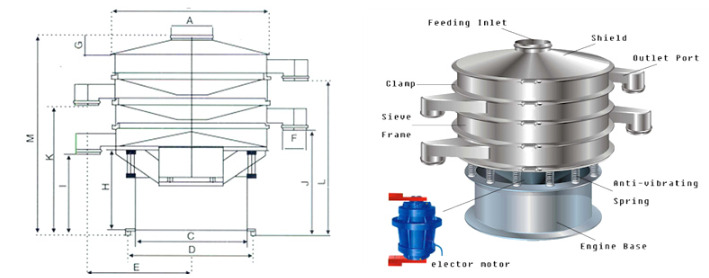

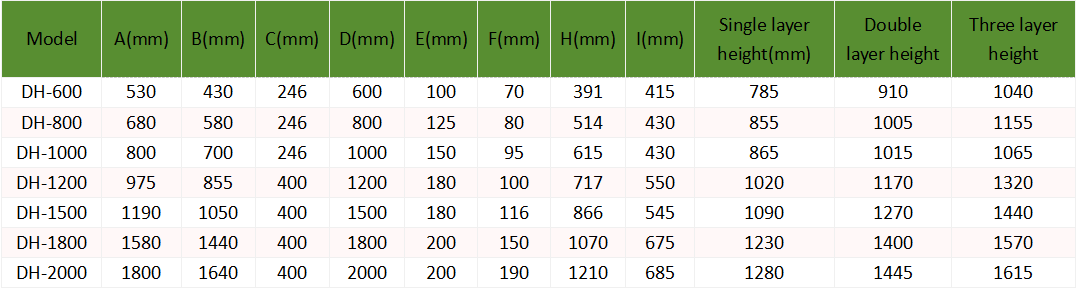

Dimensions of glaze vibrating sieve

Why do you sieve glaze?

Prevent Clogging: Sieving helps to prevent clogging of spray nozzles, pumps, or other application equipment used for applying the glaze onto the ceramic surface. This ensures a smooth and uninterrupted flow of the glaze during the application process.

Enhance Adhesion: Sieving the glaze can improve the adhesion of the glaze to the ceramic surface by ensuring that the glaze particles are of uniform size and free from any contaminants that could hinder adhesion.

Glaze vibrating sieve manufacturer

Glaze vibrating sieve is a critical step in the ceramic production process to ensure quality control, consistency in application, and the desired aesthetic and functional properties of the final ceramic products.

-

The model of vibration sieve is divided into eight equipments with different dimensions from 400-2000mm.

-

Sieve machine is a general-purpose vibrating screening and filtering equipment. The main material is divided into SUS304 stainless steel or Q235A carbon steel.

-

For safe sieving and precise grading of liquids, powders and granules, suitable for plants and factories that need to handle large volumes of products

-

For separation of different particle sizes in the same product, safe screening to eliminate foreign matter, solid-liquid separation, etc.

-

Chemical catalyst vibrating screen

Chemical catalyst vibratinACg screen is a device specially used for screening and grading chemical catalyst...

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Nylon sieve

Nylon sieve is a common screening tool, widely used in laboratories and industrial production, mainly used for screening...

-

Drying sand vibrating screen

Drying sand vibrating screen is a vibrating screening device specially used for screening dried sand. It is mainly...

-

Stone powder vibrating screen

Drying sand vibrating screen is a screening device that uses the exciting force generated by the vibrating motor to...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.