Herbal vibrating screen

Herbal vibrating screen is a device for screening, grading and removing impurities from herbal materials. It is commonly used in herbal processing and herbal pharmaceutical industries. The herbal particles are screened and graded through the vibration of the screen, making the herbs jump on the screen surface, which can effectively screen out impurities and herbal particles that do not meet the requirements in the herbs, ensuring the quality and purity of the herbal powder.

Video of the herbal vibrating screen

What are herbal vibrating screens used for?

1、Improve the quality of herbal medicines: During the collection process, herbs will be mixed with impurities such as soil, stones, branches, and weeds. Through the screening of herbal vibrating screens, these impurities can be effectively removed, the purity of herbs can be improved, and the quality and efficacy of herbs can be guaranteed.

2、Achieve precise grading: Different herbal application scenarios and formulas have different requirements for the particle size of herbs. Herbal vibrating screens can screen herbs into different particle size grades according to the size of the screen aperture, such as coarse powder, medium powder, fine powder, etc., to meet the production needs of different products such as Chinese medicine preparations and Chinese medicine slices.

3、Ensure product stability: In the process of herbal medicine production, the use of herbal vibrating screens can ensure that each batch of herbs is consistent in terms of particle size, purity, etc., which is conducive to the stability of product quality and improves the market competitiveness of products.

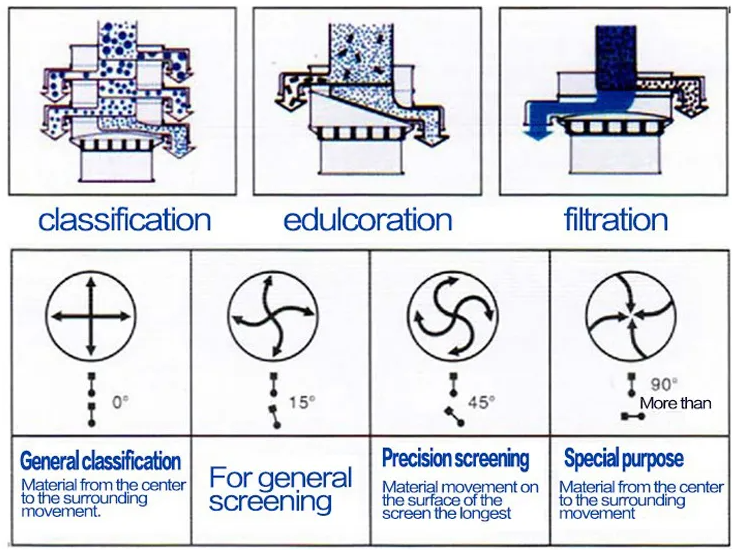

Working principle of herbal vibration screen

Vibration mode: Herbal vibration screen generates excitation force through the vibration motor, which makes the screen box vibrate in the horizontal, vertical or three-dimensional direction. The vibration makes the herbs disperse quickly on the screen surface, the fine particles pass through the screen, and the coarse particles move along the screen surface and are discharged from the discharge port.

Sieving process: The herbs enter from the top of the screen machine, and under the action of vibration, the fine particles pass through the screen, and the coarse particles move along the screen surface and are discharged from the discharge port. The multi-layer screen design can realize multi-level screening to meet different particle size requirements.

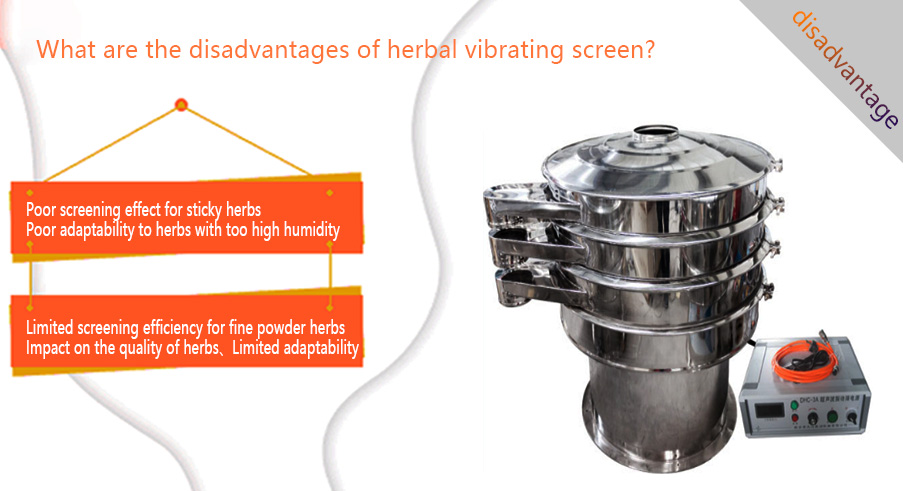

What are the disadvantages of herbal vibrating screen?

1、Poor screening effect for sticky herbs: Some herbs (such as herbs with high sugar or oil content) are easy to adhere to the screen, causing the screen to be blocked and affecting the screening efficiency. Herbal vibrating screen uses an anti-sticking screen or adds a screen cleaning device (such as a bouncing ball), or chooses an ultrasonic screening device.

2、Poor adaptability to herbs with too high humidity: Herbs with too high humidity are easy to clump, resulting in reduced screening efficiency and even blocking the screen. Herbal vibrating screen dries the herbs before screening, or chooses equipment suitable for wet material screening.

3、Limited screening efficiency for fine powder herbs: Fine powder herbs (such as herbal extracts) are easy to generate dust during the screening process, affecting the screening effect. Herbal vibrating screen adopts a fully enclosed design and is equipped with a dust removal device.

4、Impact on the quality of herbs: During the screening process, due to the effect of vibration force, herbal particles may be worn or damaged to a certain extent, thus affecting their quality. Especially for some fragile or sensitive herbs, this effect may be more significant.

5、Limited adaptability: Herbal vibrating screen may have limited adaptability for certain special types of herbs or specific screening requirements. For example, for herbal particles with a wide range of particle size distribution, it may be necessary to use multiple screens or adjust the screening parameters to meet the screening requirements, which increases the complexity and cost of the operation.

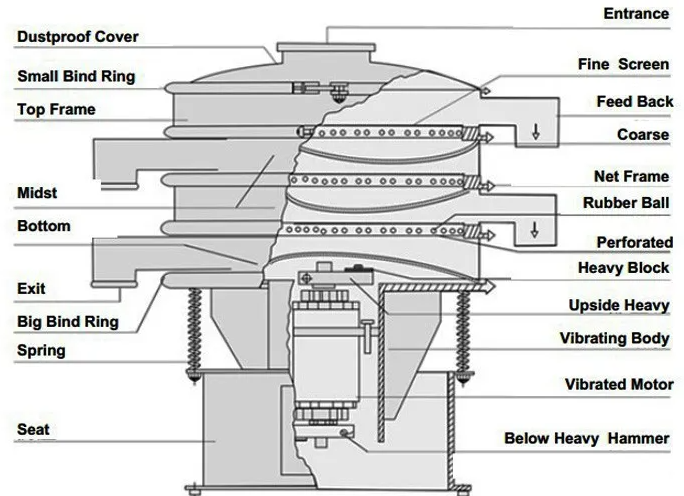

Structure of herbal vibrating screen

Herbal vibrating screen is usually composed of a screen box, a screen mesh, a vibration motor, a motor base, a bracket and other parts. The screen box is the main part that holds the material, and the screen mesh is installed in the screen box for screening the material. The vibration motor is a key component that generates the exciting force. By adjusting its vibration frequency and amplitude, the accuracy and efficiency of screening can be controlled.

Application of herbal vibrating screen

1、Primary processing of herbal medicine: After the herbs are harvested, impurities such as soil, stones, leaves, etc. are removed to improve the purity of the herbs.

2、Herbal powder processing: The ground herbal powder is screened to separate the coarse powder and fine powder, and the crushed powder is divided into different grades to meet the needs of different preparations.

3、Herbal granule processing: The prepared herbal granules are screened to select particles of uniform size to ensure the consistency of product quality.

Who is the manufacturer of herbal vibrating screens?

Dahan Vibration Machinery Co., Ltd. is a specialized manufacturer of vibrating screen equipment and vibration machinery series products. It provides complete assembly line services from design, production to sales and is committed to solving various screening problems.

Herbal vibrating screen plays an important role in the herbal processing, helping herbal manufacturers improve production efficiency and ensure the quality and purity of herbal products. This equipment is widely used in the herbal processing industry, bringing convenience and benefits to the herbal production process.

-

The model of vibration sieve is divided into eight equipments with different dimensions from 400-2000mm.

-

Sieve machine is a general-purpose vibrating screening and filtering equipment. The main material is divided into SUS304 stainless steel or Q235A carbon steel.

-

For safe sieving and precise grading of liquids, powders and granules, suitable for plants and factories that need to handle large volumes of products

-

For separation of different particle sizes in the same product, safe screening to eliminate foreign matter, solid-liquid separation, etc.

-

Chemical catalyst vibrating screen

Chemical catalyst vibratinACg screen is a device specially used for screening and grading chemical catalyst...

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Nylon sieve

Nylon sieve is a common screening tool, widely used in laboratories and industrial production, mainly used for screening...

-

Drying sand vibrating screen

Drying sand vibrating screen is a vibrating screening device specially used for screening dried sand. It is mainly...

-

Chemical screening machine

Chemical screening machine is a kind of equipment specially used for screening and grading materials in the chemical industry. It is mainly used to separate powder, granules, liquids and other materials...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.