Medical screening machine

Medical screening machine is a screening equipment designed for medical industry, used to process medical materials (such as powders, granules, pellets, etc.) to meet the needs of impurity removal, classification, deagglomeration, etc. It is mainly used in the medical, chemical, food and otherindustries to help sort materials of different particle sizes to achieve the required quality and specifications. In the medical production process, screening machines are often used to screen raw powders, granules, drug ingredients, etc. to ensure the consistency and accuracy of the final product.

Functions and effects of medical screening machines

Particle size classification: Medical screening machine selects sieves with different mesh sizes to classify materials according to particle size to ensure the uniformity and fineness of the particles.

Impurity removal: Through screening, impurities or particles that do not meet the specifications are removed to ensure the purity and quality of the medicine.

Improve production efficiency: Optimize the particle size distribution of raw materials, improve the efficiency of subsequent processing steps, and avoid production problems caused by uneven particles.

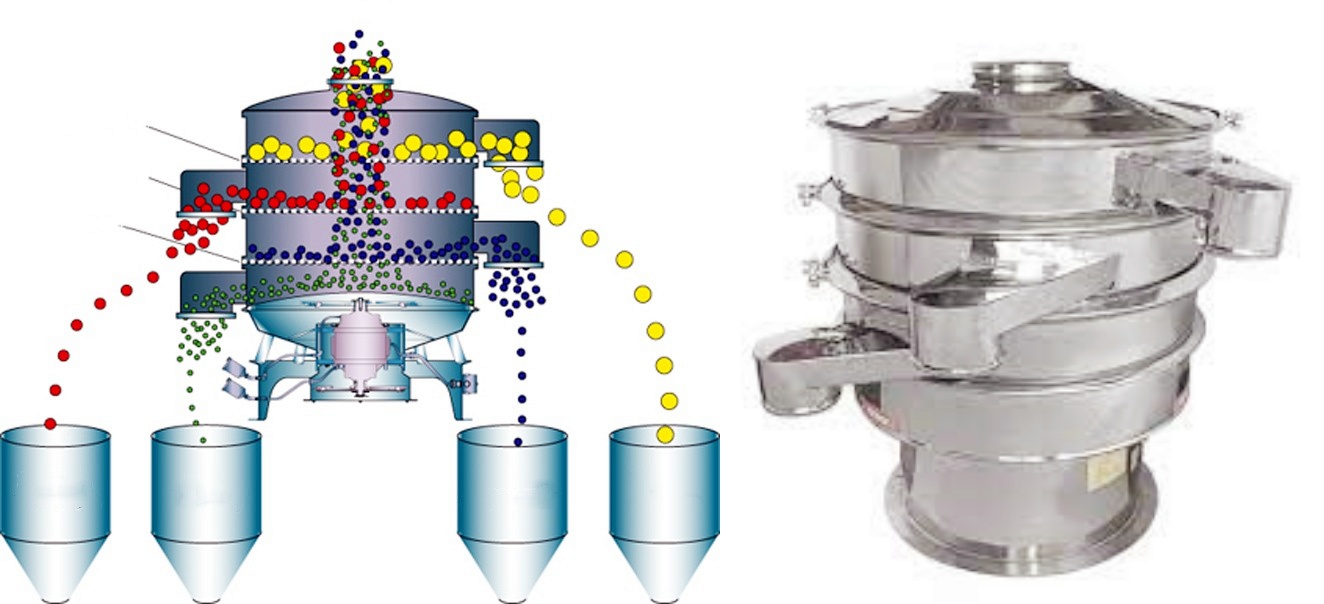

How does the medical screening machine work?

①The vibration motor or exciter drives the sieving machine to vibrate, causing the pharmaceutical powder or particles to move in a circular, linear or elliptical motion on the sieve.

②The medical powder or particles are evenly distributed under the action of the vibration force, and the smaller pharmaceutical powder or particles pass through the sieve, while the larger pharmaceutical powder or particles remain on the upper layer of the sieve and are discharged to the outlet.

Recommended mesh size for pharmaceutical screening machines

①Coarse screening (screening large particles): 20 to 80 mesh, suitable for coarse screening of larger particles of drugs, such as raw powder and granular materials.

②Medium screening (standard screening): 80 to 200 mesh, this range is often used for screening of conventional drug powders and can effectively remove impurities.

③Fine screening (ultrafine screening): 200 to 400 mesh and above, suitable for screening materials with very high particle size requirements, such as screening of ultrafine powders and high-precision drugs.

What are the advantages of medical screening machines?

1. Solving the problem of aggregation and high viscosity of medical materials: Medical screening machines can effectively break down the aggregation and viscosity between materials. Ultrasonic energy acts on the surface of the sieve, causing the material to be in a "suspended" state on the sieve surface, reducing the contact time and friction between the material and the sieve, thereby preventing material agglomeration and adhesion to the sieve, and improving the screening effect.

2. The issue of improving screening accuracy and efficiency: Medical screening machine can adjust the vibration frequency, amplitude, and direction of the vibration motor to achieve the optimal motion state of the material on the screening surface, thereby improving screening accuracy and efficiency.

3. Dealing with hygiene and pollution issues: Medical screening machines are usually made of materials such as stainless steel that meet medical and hygiene standards. The surface of the screen mesh and body is smooth, without dead corners, and easy to clean and disinfect. The structural design of some screening machines is also easy to disassemble and assemble, facilitating thorough cleaning and maintenance of the equipment interior, reducing the risk of material residue and cross contamination.

4. Addressing the complexity of medical material characteristics: Medical raw materials and intermediates may have different physical and chemical properties, such as viscosity, humidity, static electricity, etc., which can affect screening efficiency and accuracy. Medical screening machines offer various types, such as rotary vibrating screens, linear vibrating screens, and ultrasonic vibrating screens, to adapt to the characteristics of different materials.

Technical parameters of medical screening machine

|

Material type |

Recommended mesh |

Aperture range (mm) |

Application |

|

Vitamin powder |

120-200 mesh |

0.075-0.125 |

Impurity removal, packaging |

|

Medicine powder (such as antibiotics) |

150-250 mesh |

0.063-0.106 |

Preparation, tableting |

|

Chinese medicine powder |

80-150 mesh |

0.106-0.18 |

Powder, capsule filling |

|

Chinese medicine granules |

20-60 mesh |

0.25-0.85 |

Grading, packaging |

|

Micropellets |

30-80 mesh |

0.2-0.6 |

Filling, coating |

|

Lyophilized powder |

200-300 mesh |

0.05-0.075 |

Sterile preparation |

What can a medical screening machine be used for?

1. Raw material screening: Medical screening machine screens Chinese medicinal materials, Western medicine raw materials, etc. to remove impurities, foreign objects, and particles that do not meet the requirements, ensuring the purity and particle size uniformity of the raw materials, and ensuring the quality and purity of the medicinal materials.

2. Intermediate screening: In the process of drug production, medical screening machine screens intermediates and needs to screen the powder to ensure that the particle size of the powder is uniform and meets production requirements. Screening tablets can remove impurities such as fragments and foreign objects, ensure the integrity and quality of the tablets, control particle size distribution, and provide qualified materials for subsequent processes.

3. Finished drug screening: Medical screening machine screens finished drugs such as tablets, granules, capsules, etc. to remove defective products such as damage, adhesion, and uneven size, ensuring the appearance and quality of the drugs. Before drug packaging, medical screening machine can be used for final screening and inspection of finished drugs to ensure that the products meet the standards.

4. Powder grading: Medical screening machine finely grades various medical powders and can also be used in the process of drug quality inspection to screen samples and obtain powders of different particle sizes, ensuring that drugs meet standards and meet the needs of different dosage forms and processes.

Medical screening machine price

The price of a medical screening machine may vary depending on various factors, including the size, functionality, brand, technological level, and purchasing location of the machine. Generally speaking, the price of a medical screening machine may range from several thousand dollars to several million dollars.

1. Small medical screening machines: Some small medical screening machines may cost between several thousand to tens of thousands of dollars, depending on their functionality and scale.

2. Medium sized medical screening machine: Suitable for medium-sized screening experiments, the price may range from tens of thousands to hundreds of thousands of dollars.

3. Large medical screening machines: Large medical screening machines are typically used to process large amounts of samples and perform high-throughput screening, with prices ranging from tens of thousands to millions of dollars.

Medical screening machines are usually designed with precision and meet the strict requirements of the medical industry. They can efficiently and accurately screen and classify medical raw materials, improve production efficiency, and ensure the quality and safety of drugs.

-

The model of vibration sieve is divided into eight equipments with different dimensions from 400-2000mm.

-

Sieve machine is a general-purpose vibrating screening and filtering equipment. The main material is divided into SUS304 stainless steel or Q235A carbon steel.

-

For safe sieving and precise grading of liquids, powders and granules, suitable for plants and factories that need to handle large volumes of products

-

For separation of different particle sizes in the same product, safe screening to eliminate foreign matter, solid-liquid separation, etc.

-

Used to safely remove contaminants and lumps in powder.

-

Fully sealed structure, no powder overflow, no liquid overflow.

-

Flour vibrating sieve is specially designed for product safety in flour mills, bakeries and other food processing plants.

-

Sesame sieve is also called sesame sieve machine or sesame sieving machine. Sesame sieving generally refers to sieve out the sand in the sesame or the carbon residue in the fried sesame.

-

Screening and filtering of particles, powders, liquids and other materials.

-

Satisfy various powder and particle screening requirements and liquid filtration requirements.

-

Swing Vibrating Screen is a high-efficiency screening machine specially designed to meet the needs of large-scale and high-precision screening.

-

From the point of view of the material properties of flour, flour is easier to sieving, and there is no very high requirement for the screening capacity of the vibrating sieving machine.

-

Standard test sieves are precision mesh screens used to separate particles based on size in various industries.

-

Potato Starch Vibrating Screen

The discharging port can be adjusted 360 degrees arbitrarily, which is convenient to connect with the scene.

-

In the case that the mealworms are not harmed, the dry bugs are separated from the impurities, instead of manual sorting.

-

Ensure accurate particle size of metal powder and remove excessive contaminants.

-

Remove solids from liquid slurries and recover valuable materials in the waste stream for reuse.

-

Granules, powders, and paddle materials can be used.

-

Chemical catalyst vibrating screen

Chemical catalyst vibratinACg screen is a device specially used for screening and grading chemical catalyst...

-

Double layer rotary vibrating screen

Double layer rotary vibrating screen is a multifunctional and efficient screening equipment used for particle...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Nylon sieve

Nylon sieve is a common screening tool, widely used in laboratories and industrial production, mainly used for...

-

Stainless steel straight screen

Stainless steel straight screen is an efficient and durable screening equipment, mainly used for rapid screening...

-

Stone powder vibrating screen

Drying sand vibrating screen is a screening device that uses the exciting force generated by the vibrating motor...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials, easy...

-

Vibrating Sieve for Powder

Vibrating sieve for powder is a special term for the screening of powder materials in various industries. In order...

-

Stainless steel straight-discharge screen

Stainless steel straight-discharge screen is an efficient and fast screening device, specially used for screening...

-

Nylon sieve

Nylon sieve is a common screening tool, widely used in laboratories and industrial production, mainly used for...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.