Palm Nut Grading Screen Machine

Palm nut grading screen machine is a key equipment in palm oil processing production line. This equipment can grade the size of palm kernel, shell, pulp or nut, remove impurities or screen the materials after preliminary crushing by vibration, rotation or screen separation, so as to prepare for the subsequent shelling and separation processes, and ensure the processing efficiency and product quality. It is widely used in oil palm processing plants, farms, kernel recycling workshops and other links. Its purpose is to effectively grade palm fruits/kernels of different sizes to improve the efficiency and accuracy of subsequent shelling, oil pressing, recycling and other processes.

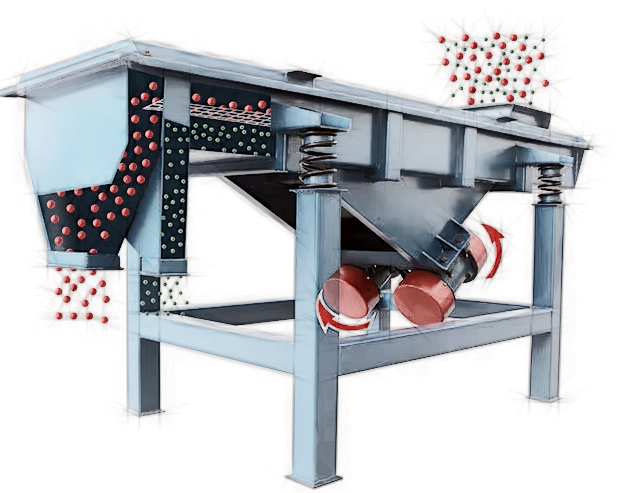

What is the working principle of palm nut grading screen machine?

Palm nut grading screen machine usually adopts the mechanical screening principle based on size difference to make materials such as palm nuts produce stratification and screening effect on the screen surface. The specific principle is as follows:

It makes nuts stratify on screens with different apertures through vibration, rotation or reciprocating motion

Small-sized nuts first leak from the smaller aperture screen, and large-sized nuts first suffocate from the expanded aperture or termination outlet

The separation after stratification enters the shell breaker respectively, and the separated kernels are extracted after the shell kernels are separated

What are the advantages of palm nut grading screen machine?

Solve the heterogeneity and impurities of palm nuts

Palm trees are often mixed with fibers, pulp, matrix or stones, which cause clogging of the screen or damage to the equipment. Heterogeneous samples lead to unreliable grading results and require multiple screening. Use palm nut grading screen machine or magnetic separator to remove stones and metals before screening.

Avoid wet stickiness and pulp residue of palm nuts

Uncompletely dried coconuts (10-20% moisture) or nuts with pulp residue are wet and sticky, easy to stick or adhere to the equipment, and wet material accumulation may also cause equipment jams. Screening machine palm nut grading and screening machine supports wet screening function, equipped with a water spray device to rinse the pulp residue and keep the screen surface clean.

Reduce the risk of grease and screen clogging

Pulp or grease often remains on the surface of nuts, which is easy to clog the aperture (especially the small hole screen <15 mm), resulting in reduced screening efficiency, inaccurate screening, and interruption of small nuts mixing into large nuts. Palm nut grading screen machine uses stainless steel mesh or surface coating to reduce grease application.

Dealing with the problem of uneven size of palm nuts

The uneven size of palm nuts will lead to low efficiency and large error in single-layer screening. Palm nut grading screen machine uses 3~5 layers of screen combination (such as 20mm→15mm→10mm), with grading accuracy ≥95%, and production capacity increased by 40%

Recommended mesh number of palm nut grading screen machine

In the actual application of palm nut grading screen machine, the selection of mesh number is very critical, which will directly affect the screening accuracy, subsequent shelling rate and whole kernel rate.

|

Grading target |

Screen mesh number |

Corresponding aperture (mm) |

Applicable scenarios |

|

Extra large fruit (seedling/oil pressing) |

3~5 mesh |

6.35~4.76 |

It can screen mature fruit with high oil content |

|

First-level fruit (high-quality processing) |

6~8 mesh |

3.36~2.38 |

It can process food-grade palm kernels and chocolate raw materials |

|

Second-level fruit (ordinary raw materials) |

10~12 mesh |

2.00~1.68 |

It is suitable for secondary raw materials for oil pressing or feed additives |

|

Broken fruit/impurities |

14~16 mesh |

1.41~1.19 |

Abandon or re-crush for use |

What is the application of palm nut grading screen machine?

Palm nut grading screen machine plays a vital role in the entire oil palm industry chain. It is not only an important equipment for screening and grading, but also a core tool for improving product quality, optimizing production efficiency and reducing labor costs.

Primary kernel screening after palm fruit threshing

This equipment can roughly screen the mixture (kernel + fruit branch + peel + debris) after threshing, remove large pieces of peel, fruit branch and other coarse debris, and separate the main usable kernels.

Grading and sorting of palm kernels before shelling

The screen machine can grade and screen kernels of different sizes, match the kernel-shell ratio for the shelling equipment, and divide them into three categories: large kernels, medium kernels, and small kernels, so as to improve the shelling efficiency and kernel rate, and exclude unqualified or broken kernels.

Separation of shell-kernel mixture (shell-kernel specific gravity is close)

Palm nut grading screen machine can further screen the residual shell and kernel in the shell-kernel mixture to separate the large kernels that are not completely shelled.

Kernel selection before oil pressing

It can remove small broken kernels, fibers, and sand and gravel to ensure that pure kernels enter the press, improve oil pressing efficiency, reduce impurities entering the oil system, and ensure oil quality and stability.

Biomass fuel shell screening and purification

The machine screens the shells from the mixture for carbonization, biofuel briquetting, etc., improves the purity of the shells, and removes the mixed kernels, sand, impurities, etc.

Sample sorting in laboratories/variety improvement stations

Palm nut grading screen machine is used for rapid screening and comparison of small batches of kernel samples, precise grading of kernels of different strains, and is used to study kernel size, shell thickness, kernel yield and other data.

Actual cases of palm nut grading screen machine

Small and medium-sized palm oil factories in Nigeria:

Problem: Natural nuts are 10-40 mm in size, containing pulp and soil, the screen is often silted, and the grading efficiency is low (1t/h).

Solution: Use palm nut grading screen machine (aperture 12, 18, 25mm), clean the effective flesh in the pre-process, add anti-stick coating to the screen, and equip with 5kW motor, the efficiency is increased to 1.8t/h, and the grading screen is <3%.

Large factories in Malaysia:

Problem: High throughput (10 t/h), replacement of hard shell fatigue screens, frequent replacement (once every 3 months).

Solution: Choose a 15kW palm nut grading screen machine, 5 layers of stainless steel perforated plates, plus a buffer feed trough, the screen life is extended to 6 months, and the pollutants are stabilized at 12t/h.

If you have a specific material screening scenario (such as small farmers, industrial production lines, or a specific size range such as 15-20 mm), or want to study certain issues (such as grease treatment, screen selection), Dahan Machinery can provide more details and can further customize solutions or recommend equipment models according to your needs!

-

Potato Starch Vibrating Screen

Granules, powders, and paddle materials can be used.

-

Screening black soldier fly feces and larvae can separate the worms and feces, saving labor.

-

Ensures removal of contaminants such as large particles and agglomerates from metal powders, providing accurate particle size distribution

-

Remove solids from liquid slurries and recover valuable materials in the waste stream for reuse.

-

Desert sand sieving machine

Desert sand sieving machine is a mechanical equipment used for sand and gravel processing or sieving...

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Vibrating screen for coal gangue screening

Z-type bucket elevator for peanut conveying is a vertical lifting equipment specially designed for fragile or soft conveying...

-

EVA Polymer Powder Sieving Machine

EVA polymer powder sieving machine is a device specially used for sieving ethylene-vinyl acetate copolymer...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.