EVA Polymer Powder Sieving Machine

EVA polymer powder sieving machine is a device specially used for sieving ethylene-vinyl acetate copolymer (EVA) powder. It is usually used in industrial production to classify EVA powder according to particle size to ensure that the powder particle size is uniform and meet specific application requirements (such as manufacturing foam materials, adhesives or other products). It can also be widely used in plastic processing, modified material preparation, foam material production and other fields.

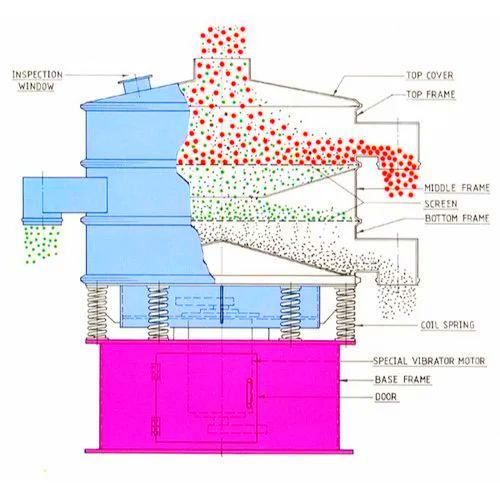

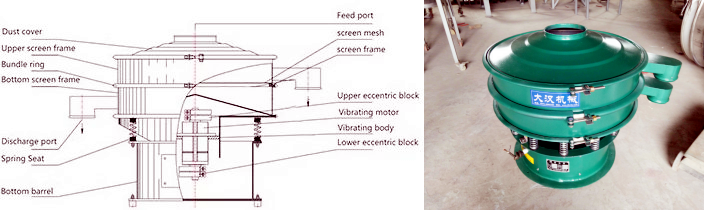

What is the working principle of EVA polymer powder sieving machine?

EVA polymer powder sieving machine uses a multi-layer screen structure to vibrate The EVA powder forms a thin layer on the screen surface, and the particle size difference is used to achieve classification.

The sieve hole size is designed according to the target particle size. For example, a 100-mesh sieve corresponds to an aperture of about 150μm, allowing particles smaller than this size to pass through.

What are the advantages of EVA polymer powder sieving machine?

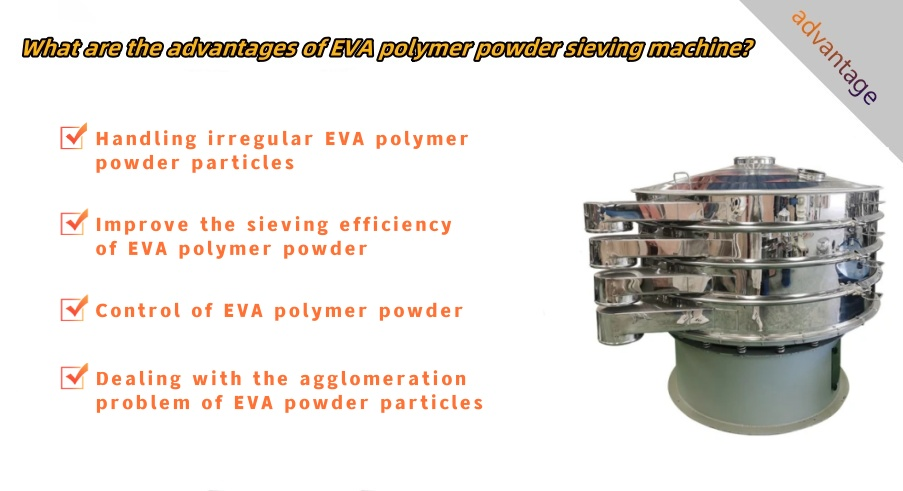

EVA polymer powder does face some unique challenges during the sieving process, mainly due to its physical and chemical properties, such as softness, viscosity, electrostatic effects, and irregular particle shapes. Analysis of how the EVA polymer powder sieving machine specifically solves these problems:

Handling irregular EVA polymer powder particles

EVA polymer powder sieving machine sets different apertures to The multi-layer screen can gradually separate particles of different shapes and sizes. It can also use the centrifugal force generated by the rotating blades to push irregular particles to the screen and force them to pass through, which is suitable for processing EVA powders with complex shapes.

Improve the sieving efficiency of EVA polymer powder

EVA polymer powder sieving machine can effectively screen ultra-fine EVA powders above 10 microns without screen clogging. Use high-precision woven screens (such as nylon or metal mesh, with a mesh count of up to 500 mesh) to ensure efficient separation of fine particles.

Control of EVA polymer powder

Sieving fine EVA polymer powder will generate a lot of dust, bring safety risks, and may cause material Material loss. EVA polymer powder sieving machine can be integrated with the dust collection system to safely remove particles from the air. Most sieving machines use a fully enclosed system.

Dealing with the agglomeration problem of EVA powder particles

The fine EVA powder particles have a high surface area to volume ratio, which leads to strong cohesive forces between them, causing them to stick to each other and form agglomerates. These agglomerates will clog the screen and hinder the passage of individual particles. By adjusting the vibration frequency and amplitude of the machine, the particles are allowed to pass through the screen smoothly.

Recommended mesh number of EVA polymer powder sieving machine

|

Target particle size |

approximate micron range (µm) |

Corresponding mesh size |

Notes |

|

Coarse |

>500 |

<35 |

It is used to remove very large agglomerates or contaminants |

|

Medium coarse |

250-500 |

35-60 |

|

|

Medium fine |

100-250 |

60-140 |

Common range for many polymer powder applications |

|

Fine |

44-100 |

140-325 |

Applicable for finer particle size requirements |

|

Very good |

<44 |

>325 |

Often referred to as micronization; specialized sieving methods such as ultrasonic or airflow EVA polymer powder sieving machine may be required |

Application of EVA polymer powder sieving machine

Hot melt adhesive manufacturing industry

EVA is one of the core raw materials of hot melt adhesive. In order to ensure that the hot melt adhesive after melting is uniform and has strong adhesion, the particle size distribution of EVA powder needs to be strictly controlled. EVA polymer powder sieving machine finely sieves the EVA powder (such as 80~200 mesh), removes the agglomerated materials, ensures uniform mixing, and improves the fluidity of the hot melt adhesive and the consistency of the finished product.

Foamed shoe material (EVA sole) manufacturing

EVA powder is an important component of the shoe material foaming process. Too coarse or uneven powder will lead to uneven foaming, too large pores, and unstable product quality. EVA polymer powder sieving machine can control the particle size of the EVA powder within the ideal range (such as 60~100 mesh), remove large particles and impurities, ensure uniform foaming, and improve the comfort of the sole.

Photovoltaic industry (EVA solar encapsulation film)

EVA film is used as an encapsulation material in solar cell modules, and its powder raw material must be clean and have a precise particle size distribution. It can screen out impurities and foreign matter, avoid defects in the finished film, ensure consistent powder particle size, and promote uniform extrusion and melting

Preparation of cable insulation materials

EVA powder is used for cable sheath materials, requiring high powder purity and stable particle size to ensure electrical insulation performance. This machine can select pure fine powder to avoid hard particles affecting cable extrusion and improve the mechanical properties and aging resistance of the insulation layer

3D printing consumables and composite materials

EVA powder is also gradually used in lightweight 3D printing particles and rubber-plastic composite materials, which have high requirements for particle grading. The machine can accurately control the powder fineness, improve the stability of the printing layer, and improve the uniformity and bonding strength of the composite material

EVA polymer powder sieving machine not only realizes simple particle size classification, but also meets the special needs of various industries through professional design. Different application scenarios have significant differences in equipment configuration requirements, and the most suitable sieving solution needs to be selected according to the specific production process. Do you need to know more detailed technical parameters or equipment selection recommendations for a specific application field? You can contact our customer service or send it via email.

-

Potato Starch Vibrating Screen

Granules, powders, and paddle materials can be used.

-

Screening black soldier fly feces and larvae can separate the worms and feces, saving labor.

-

Ensures removal of contaminants such as large particles and agglomerates from metal powders, providing accurate particle size distribution

-

Remove solids from liquid slurries and recover valuable materials in the waste stream for reuse.

-

Plastic granules square swing screen

Plastic granules square swing screen is a device specially used for screening plastic granules. It is suitable for...

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Drying sand vibrating screen

Drying sand vibrating screen is a vibrating screening device specially used for screening dried sand. It...

-

Vibrating screen for coal gangue screening

Vibrating screen for coal gangue screening is a kind of equipment specially used for grading and...

-

Vibrating screen for coal gangue screening

Z-type bucket elevator for peanut conveying is a vertical lifting equipment specially designed for fragile or soft conveying...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.