Soy milk rotary vibrating sieve

Soy milk rotary vibrating sieve is a device used to filter and screen soy milk during the soy milk production process. It separates impurities such as particles and fibers from the soy milk by rotating and vibrating, ensuring that the soy milk has a fine texture and a smooth taste. This equipment can help soy milk manufacturers improve production efficiency while ensuring that the quality of soy milk products meets standards.

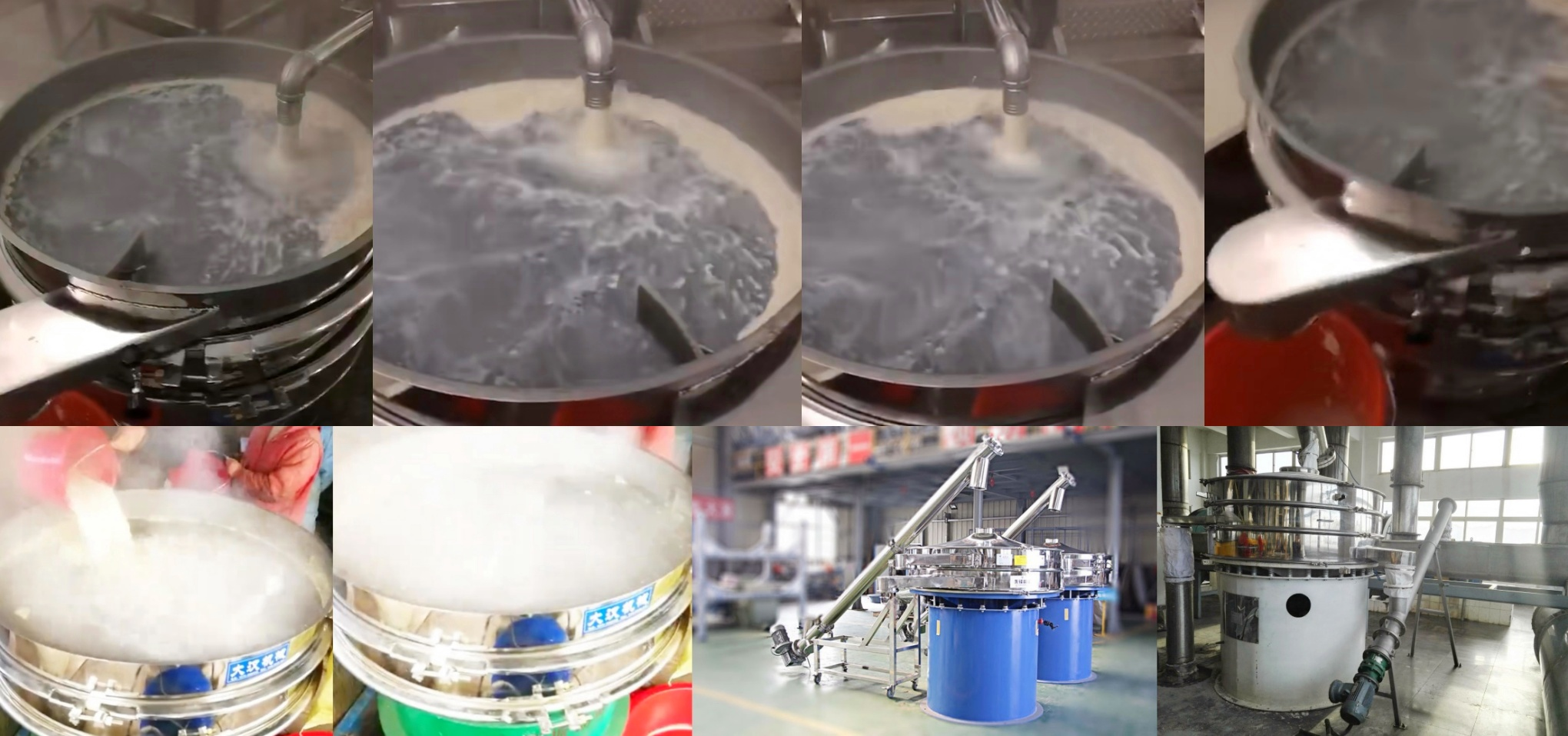

Video of soy milk rotary vibrating screen

What is the working principle of the soy milk rotary vibrating screen?

Soy milk rotary vibrating screen uses the exciting force generated by the vibration motor to make the screen vibrate at high frequency.

Soy milk enters the screen through the feed port. Under the action of the vibration force, the liquid and fine particles pass through the screen, while the larger solid particles are left on the screen, thus achieving separation.

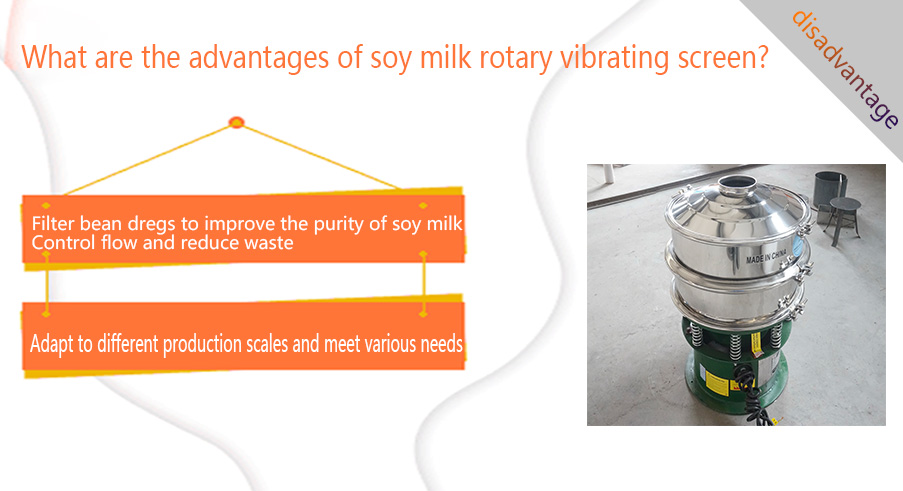

What are the advantages of soy milk rotary vibrating screen?

1. Filter bean dregs to improve the purity of soy milk

During the soy milk grinding process, a large amount of bean dregs will be produced. High-precision stainless steel screens (40-200 mesh) can be used to effectively remove the bean dregs and ensure that the soy milk is delicate and uniform.

2. Control flow and reduce waste

During the soy milk transportation process, the flow control is unstable, which can easily lead to uneven screening or soy milk waste. The soy milk rotary vibrating screen is equipped with an adjustable discharge port to flexibly control the soy milk discharge speed to prevent accumulation or excessive discharge.

3. Adapt to different production scales and meet various needs

Different manufacturers have different requirements for soy milk screening, such as small workshops have lower requirements, while large soy product factories require high-yield equipment. Soy milk rotary vibrating screens are available in a variety of specifications (400mm, 600mm, 800mm, 1200mm, etc.) to meet different production capacity requirements.

Recommended mesh size for soy milk rotary vibrating sieve

|

Application scenario |

recommended mesh size |

aperture range (mm) |

Applicable instructions |

|

Preliminary filtration (family/small workshop) |

60 mesh-100 mesh |

0.25-0.15 |

Quickly separate larger dregs, suitable for traditional coarse-tasting soy milk, high efficiency, good slurry yield |

|

Refined soy milk (tofu/soy milk) |

120 mesh-200 mesh |

0.125-0.074 |

Remove fine particles, suitable for tofu coagulation or soy milk production, ensuring delicate taste and quality |

|

Ultra-fine soy milk (high-end soy milk/powder) |

250 mesh-400 mesh |

0.061-0.037 |

Extremely smooth, suitable for high-end soy milk or soy milk powder, requires anti-blocking device, low slurry yield |

|

Grading screening (multi-layer combination) |

80 mesh+150 mesh |

0.18+0.106 |

Upper layer coarse filtration of dregs, lower layer refined soy milk, suitable for medium-sized processing plants, taking into account both efficiency and quality |

|

Grading screening (multi-layer combination) |

120 mesh + 200 mesh |

0.125+0.074 |

More refined grading, suitable for high-quality bean product production lines, excellent separation effect |

Precautions for soy milk rotary vibrating screen

Relationship between pulp discharge rate and mesh number: the higher the mesh number, the lower the pulp discharge rate (the amount of liquid passing through the screen is reduced). It is recommended to balance the mesh number selection according to the actual production capacity requirements.

Soy milk concentration: high-concentration soy milk (such as undiluted raw pulp) is easy to clog the fine mesh. It is recommended to dilute it before screening, or choose a rotary vibrating screen with a net cleaning function.

Material requirements: The screen should be made of food-grade stainless steel (such as 304 or 316), which is corrosion-resistant and meets hygiene standards.

Application of soy milk rotary vibrating screen

1. Basic links in soy milk production: primary filtration and fine filtration

After soy milk is ground, a large amount of bean dregs will be produced. In the primary filtration stage, the rotary vibrating screen is used to quickly remove these coarse bean dregs. In the fine filtration stage, the soy milk rotary vibrating screen uses a finer screen to further improve the fineness and taste of the soy milk.

2. Application of soy milk deep processing

In the production process of soy milk powder, the rotary vibrating screen is used to screen the dried soy milk powder to remove lumps and impurities. When producing soy milk beverages with other ingredients added, it can be used to remove impurities in additives and ensure the taste of the product.

3. Wide application in the catering industry

In order to ensure the uniformity of soy milk quality, chain restaurants will use rotary vibrating screens for standardized production. Some specialty snack shops that have high requirements for the taste of soy milk will also use soy milk rotary vibrating screens to improve product quality.

Price of soy milk rotary vibrating screen

The price of soy milk rotary vibrating screens varies depending on factors such as model, brand, and material. Generally speaking, the price of the more common soy milk rotary vibrating screens on the market ranges from several thousand yuan to tens of thousands of yuan. The specific price needs to be selected according to the actual needs and budget of the customer.

Soy milk rotary vibrating sieve plays an important role in soy milk production, helping soy milk producers improve production efficiency, optimize product quality, and play an important role in all aspects of the soy milk industry.

-

Potato Starch Vibrating Screen

Granules, powders, and paddle materials can be used.

-

Screening black soldier fly feces and larvae can separate the worms and feces, saving labor.

-

Ensures removal of contaminants such as large particles and agglomerates from metal powders, providing accurate particle size distribution

-

Remove solids from liquid slurries and recover valuable materials in the waste stream for reuse.

-

Cashew linear vibrating screen

Cashew linear vibrating screen is a linear vibrating screening device specially used for screening...

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Nylon sieve

Nylon sieve is a common screening tool, widely used in laboratories and industrial production, mainly...

-

Drying sand vibrating screen

Drying sand vibrating screen is a vibrating screening device specially used for screening dried sand. It...

-

Vibrating screen for coal gangue screening

Vibrating screen for coal gangue screening is a kind of equipment specially used for grading and...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.