Vibrating screen for coal gangue screening

Vibrating screen for coal gangue screening is a kind of equipment specially used for grading and screening of gangue, which is widely used in the coal industry. Gangue is solid waste generated in the process of coal mining and washing, containing a certain amount of coal and impurities. Vibrating screen for coal gangue screening can separate it according to particle size for subsequent resource utilization (such as extracting residual coal, making bricks or power generation) or proper disposal.

Video of vibrating screen for coal gangue screening

Importance of vibrating screen for coal gangue screening

1. Resource utilization: Gangue is solid waste generated in the process of coal mining and washing. Reasonable screening can extract useful components from it and realize resource recycling.

2. Environmental protection: Gangue accumulation will occupy land and may cause environmental problems such as spontaneous combustion and dust pollution. Screened gangue can be used in filling, building materials and other fields to reduce environmental pollution.

3. Economic benefits: Through the screening of the gangue screening vibrating screen, valuable materials such as coal and pyrite in the gangue can be separated to improve economic benefits.

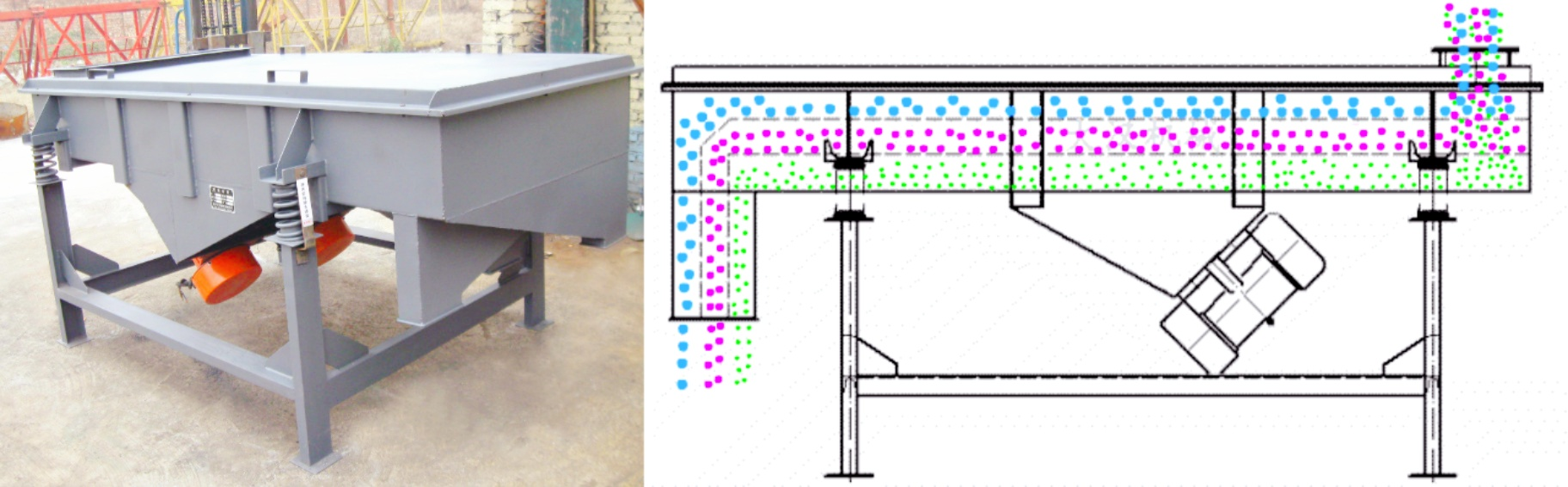

How does the vibrating screen for coal gangue screening work?

Vibrating screen for coal gangue screening generates periodic vibrations through a vibrating motor or an exciter, so that the gangue materials on the screen surface move and layer under the action of gravity and vibration. Gangue of different particle sizes will be separated through the sieve holes. Usually, the size of the sieve holes can be customized according to needs, such as from a few millimeters to tens of millimeters.

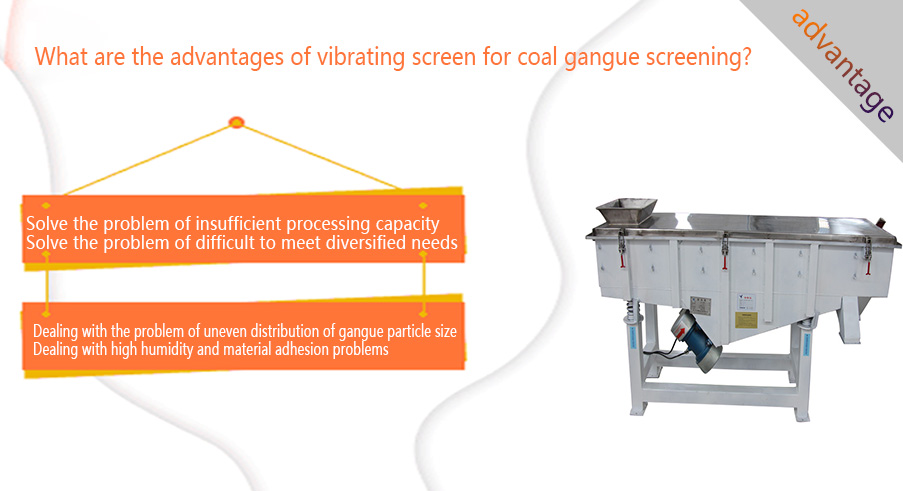

What are the advantages of vibrating screen for coal gangue screening?

1. Solve the problem of insufficient processing capacity: Traditional screening equipment may not be able to meet the needs of large-scale gangue processing. By using a large vibrating screen for coal gangue screening or multiple gangue screening vibrating screens in parallel, the overall processing capacity can be improved.

2. Solve the problem of difficult to meet diversified needs: Gangue has a variety of uses (such as power generation, brick making, and landfill), and a single device is difficult to adapt to all scenarios. By adjusting the amplitude, frequency and screen inclination of vibrating screen for coal gangue screening, it can adapt to different materials and uses.

3. Dealing with the problem of uneven distribution of gangue particle size: The particle size range of gangue is wide, ranging from large pieces (>50mm) to powder (<1mm), and a single screen hole is difficult to meet all needs. Vibrating screen for coal gangue screening adopts a multi-layer screen combination. The upper large aperture (such as 50mm) screens out large pieces, and the lower small aperture (such as 5mm) screens out fine materials to achieve graded screening.

4. Dealing with high humidity and material adhesion problems: Gangue often contains moisture (humidity can reach 10%-20%), and wet and sticky materials are easy to clog the screen holes, reducing screening efficiency. By adjusting the vibration motor parameters of vibrating screen for coal gangue screening, the material beating amplitude is increased and accumulation is reduced.

Recommended mesh number of vibrating screen for coal gangue screening

|

Screening purpose |

Recommended mesh number |

Corresponding aperture (mm) |

Applicable scenarios |

|

Coarse screening |

4-10 mesh |

4.75-2.00 |

Used to separate larger gangue blocks, preliminary screening |

|

Medium screening |

10-20 mesh |

2.00-0.85 |

Used to screen medium-sized materials, separating medium-sized gangue and coal |

|

Fine screening |

20-40 mesh |

0.85-0.425 |

Used to screen smaller-sized materials, separating fine gangue and coal |

|

Fine screening |

40-60 mesh |

0.425-0.250 |

Used for fine screening, Separate finer gangue and coal particles |

|

Ultrafine screening |

60-100 mesh |

0.250-0.150 |

Used for screening ultrafine materials, suitable for occasions with high particle size requirements |

|

Dust screening |

100-200 mesh |

0.150-0.075 |

Used for screening dust and ultrafine particles in gangue, suitable for environmental protection and recycling |

Application of vibrating screen for coal gangue screening

1. Coal washing plant: During the coal washing process, gangue is mixed with coal. Large pieces of gangue need to be separated by vibrating screen for coal gangue screening, and the washed gangue is graded for subsequent processing.

2. Comprehensive utilization of gangue: Gangue can be used for brick making, cement production, paving, filling subsidence areas, etc. Vibrating screen for coal gangue screening is used to screen gangue into different particle sizes to meet the needs of different uses.

3. Gangue power plant: Gangue can be used for power generation, but it needs to be crushed and screened into a particle size suitable for combustion. Vibrating screen for coal gangue screening is used to screen the crushed gangue to separate particles suitable for combustion.

4. Gangue landfill: Gangue landfill is a traditional treatment method, but gangue needs to be graded to reduce environmental pollution. Vibrating screen for coal gangue screening is used to screen gangue into different particle sizes for easy layered landfill.

Vibrating screen for coal gangue screening is a device used to separate materials of different particle sizes in gangue, which is widely used in the coal industry. With the improvement of the industry's requirements for environmental protection and efficiency, vibrating screen for coal gangue screening is developing towards intelligence, efficiency and energy saving.

-

Potato Starch Vibrating Screen

Granules, powders, and paddle materials can be used.

-

Screening black soldier fly feces and larvae can separate the worms and feces, saving labor.

-

Ensures removal of contaminants such as large particles and agglomerates from metal powders, providing accurate particle size distribution

-

Remove solids from liquid slurries and recover valuable materials in the waste stream for reuse.

-

Vibrating screen for coal gangue screening

Vibrating screens play a vital role in screening coal gangue in the coal mining industry and related ...

-

Vibrating screen for chemical powder screening

Vibrating screen for chemical powder screening refers to the equipment used in the chemical industry...

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Nylon sieve

Nylon sieve is a common screening tool, widely used in laboratories and industrial production, mainly used for screening...

-

Drying sand vibrating screen

Drying sand vibrating screen is a vibrating screening device specially used for screening dried sand. It is mainly...

-

Stone powder vibrating screen

Drying sand vibrating screen is a screening device that uses the exciting force generated by the vibrating motor to...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.