Ultrasonic inline screen

What is an ultrasonic inline screen

Ultrasonic inline screen is an efficient screening equipment that combines ultrasonic technology and vibration screening principles. It is mainly used for screening fine powders, ultrafine powders, and materials with high viscosity and easy agglomeration. It effectively solves the problem of screen clogging through ultrasonic vibration system, improves screening efficiency and accuracy, and is widely used in industries such as food processing, chemical, pharmaceutical/building materials, environmental protection, metallurgy, etc.

Ultrasonic inline screen video

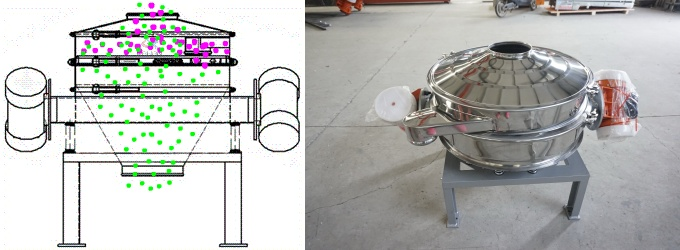

How do the ultrasonic inline screen work?

1、Ultrasonic vibration system: The ultrasonic generator generates high-frequency electrical signals, which are converted into mechanical vibrations through the transducer. The vibration is transmitted to the screen, causing the screen to produce high-frequency micro-vibrations.

2、Screening process: The material enters the screen surface from the feed inlet. Under the action of ultrasonic vibration and screen machine vibration, fine particles pass through the screen holes, while coarse particles move along the screen surface and are discharged from the discharge port. Ultrasonic vibration effectively prevents materials from blocking the screen holes, ensuring continuous and efficient screening.

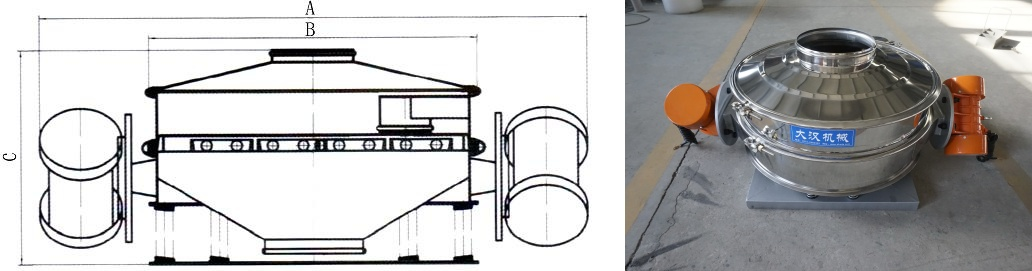

Ultrasonic inline screen design

The ultrasonic straight screen is mainly composed of a feed port, dust cover, vibration motor, ultrasonic system (ultrasonic power supply, ultrasonic transducer), spring, base, discharge port and other parts. The transducer is usually of the top-mounted type, and the material under the screen can be discharged directly, with rapid discharge and large output.

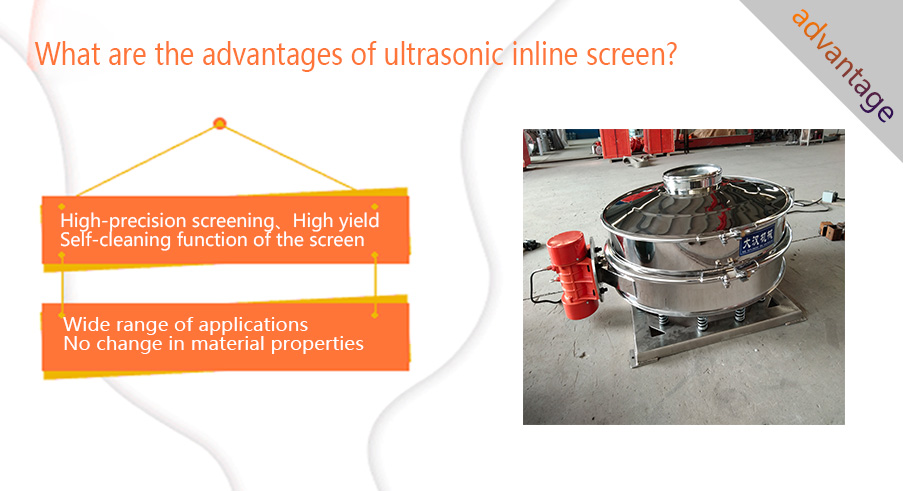

What are the advantages of ultrasonic inline screen?

1. High-precision screening: Ultrasonic inline screen can clearly separate ultrafine particles with similar diameters, and the screening accuracy can be increased by 10%-70%.

2. High yield: Compared with traditional screening equipment, the output of ultrasonic inline screen can be increased by 0.5-10 times. The material is not easy to block the screen under the action of ultrasonic vibration, and the screening efficiency is high.

3. Self-cleaning function of the screen: The ultrasonic inline screen effectively prevents the mesh from being blocked, and there is no need to add an anti-blocking net device, which avoids the contamination of the material by auxiliary materials such as bouncing balls.

4. Wide range of applications: Ultrasonic inline screen can screen special materials such as strong adsorption, easy agglomeration, high static electricity, high fineness, high density, and light specific gravity.

5. No change in material properties: During the screening process, the ultrasonic inline screen will not affect the physical and chemical properties of the material, ensuring the quality of the material.

What are the types of ultrasonic inline screen?

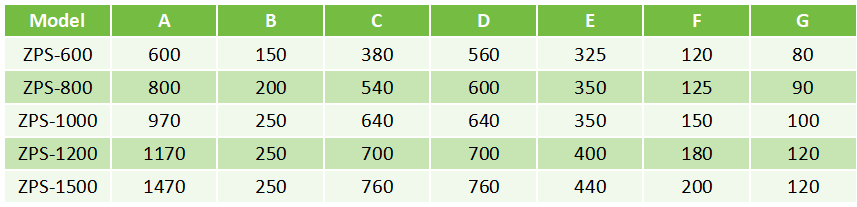

Technical parameters of ultrasonic inline screen

Application fields of ultrasonic inline screen

Ultrasonic inline screen is widely used in food processing, chemical industry, medicine and other industries. In the food processing industry, it is often used for screening and grading of powdered and granular food raw materials, such as flour, starch, powdered sugar, etc. In the chemical industry, it is often used for screening and fine grading of chemical raw materials and granular materials. In the pharmaceutical industry, it can be used for screening and classification of medicinal raw materials such as medicinal materials, powders, and Chinese medicine granules. In addition, ultrasonic inline screen is also suitable for building materials, environmental protection, metallurgy and other fields.

In summary, ultrasonic inline screens are widely used in different industries and places due to their efficient, accurate and reliable screening effects.

-

Swing Vibrating Screen is a high-efficiency screening machine specially designed to meet the needs of large-scale and high-precision screening.

-

Standard test sieves are precision mesh screens used to separate particles based on size in various industries, ensuring accurate particle size analysis and quality control.

-

Used to safely remove contaminants and lumps in powder

-

For separation of different particle sizes in the same product, safe screening to eliminate foreign matter, solid-liquid separation, etc.

-

Horizontal airflow screen

Horizontal airflow screen, also known as the cyclone screen, is a device specially used for screening fine powders and powder materials...

-

Polyethylene granule slap screen

Polyethylene granule slap screen is a vibrating screening device specially used for screening polyethylene...

-

Chemical catalyst vibrating screen

Chemical catalyst vibratinACg screen is a device specially used for screening and grading chemical catalyst...

-

Double layer rotary vibrating screen

Double layer rotary vibrating screen is a multifunctional and efficient screening equipment used for particle size classification...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Stone powder vibrating screen

Drying sand vibrating screen is a screening device that uses the exciting force generated by the vibrating motor to...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.