63 filter screen

63 filter screen usually refers to a filter screen with a pore size of 63 microns (µm). 63 microns refers to the size of the holes on the screen, that is, the maximum particle size that can pass through the screen. This type of screen is widely used in many industries to separate and filter substances of different particle sizes. Common filter screen materials include stainless steel, nylon, polyester, etc. Among them, stainless steel is the most widely used due to its corrosion resistance, high temperature resistance and high strength.

Video of 63 filter screen

How does the 63 filter screen work?

1. Sample loading: Place the material to be screened into the top screen frame of the 63 filter screen.

2. Vibration or shaking: Vibrate or shake the screen frame and screen through manual or mechanical vibration devices.

3. Particle movement: Vibration or shaking causes the material particles to move on the screen, and particles smaller than 63 microns pass through the screen, while particles larger than 63 microns remain on the screen.

4. Grading collection: The particles passing through the screen are collected by the bottom cover, and the particles remaining on the screen can be further processed.

Structural features of 63 filter screen

Precise filtration: The pore size of 63 microns can achieve precise filtration of materials and remove particles and impurities of specific sizes.

Various materials: The materials of the screen and screen frame can be selected according to the characteristics of the material and have good adaptability.

Compact structure: The structure design of the filter screen is compact, occupies little space, and is easy to install.

Easy to maintain: Parts such as the screen and sealing device are easy to disassemble and replace, which is convenient for cleaning and maintenance.

What are the advantages of 63 filter screen?

1. Material compatibility: When filtering different materials, the material compatibility of the screen needs to be considered to prevent corrosion or other chemical reactions. For example, when filtering acidic or alkaline materials, it is necessary to choose a corrosion-resistant screen material. Stainless steel is a commonly used material for 63-micron filter screens. It has good corrosion resistance and chemical stability and can adapt to the filtering needs of a variety of materials.

2. Fine filtration: 63 filter screen has a very small mesh size and is suitable for occasions where fine filtration is required. It can effectively filter out smaller particles or impurities to ensure that the filtered material is of high quality. The use of a 63-micron filter screen can achieve precise separation of fine particles or tiny solid particles in the solution, which helps to improve the purity and quality of the product.

3. Remove impurities: The material may contain various impurities, such as dust, particles, fibers, etc., which will affect the quality and performance of the product. In liquid filtration, suspended solid particles also need to be effectively removed. 63 filter screen can effectively remove tiny impurities in the material and improve the purity and cleanliness of the material.

4. Improve product quality: By using a 63 micron filter screen, fine particles or impurities can be effectively removed, thereby improving the quality of the final product and reducing the defective rate. Some industries or applications may have specific requirements for the particle size and purity of the product. Using a 63 micron filter screen can meet these requirements and ensure that the product meets the standards.

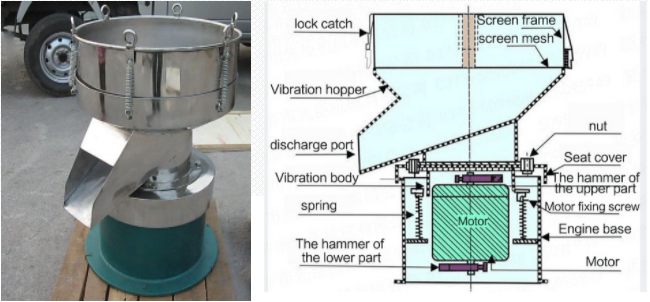

The structure of the 63 filter screen

The structure of the 63 filter screen mainly includes several core parts such as the screen, screen frame (support structure), sealing device, inlet and outlet, support feet, pressure gauge, etc. These parts work together to achieve accurate filtration of materials. Through the reasonable coordination of these structures, the 63 filter screen can effectively complete the filtration task of materials and meet the filtration needs of different industries.

63 mesh filter mesh recommendation

Application of 63 filter screen

1、Food industry: 63 filter screen can be used for screening powdery materials such as flour and powdered sugar to remove lumps and impurities; it can also be used for filtering liquids such as juice and soy milk to remove pulp fibers, residues, etc.

2、Chemical industry: In the production of coatings and inks, it is used to filter pigment particles and impurities to ensure the fineness and uniformity of the product; 63 filter screen can also be used for screening chemical raw material powders to ensure that the particle size of the raw materials meets production requirements.

3、Pharmaceutical industry: Screening of drug powders to ensure that the drug particles reach the specified particle size range to ensure the quality and efficacy of the drugs; 63 filter screen can also be used for filtering Chinese medicine extracts to remove insoluble impurities.

4、Aquaculture industry: For example, in aquaculture, 63 filter screen can be used to filter impurities such as fish feces and leftover bait in fish tanks or fish ponds to keep the water clean.

5、Laboratory: In scientific research experiments, 63 filter screens are used to perform particle size analysis and screening experiments on various powdered and granular samples to provide samples that meet the requirements for research.

63 filter screen can effectively solve various problems and challenges in the material filtration process. It is widely used in many industries and is an important tool to ensure product quality and improve production efficiency.

-

The model of vibration sieve is divided into eight equipments with different dimensions from 400-2000mm.

-

Sieve machine is a general-purpose vibrating screening and filtering equipment. The main material is divided into SUS304 stainless steel or Q235A carbon steel.

-

For safe sieving and precise grading of liquids, powders and granules, suitable for plants and factories that need to handle large volumes of products

-

For separation of different particle sizes in the same product, safe screening to eliminate foreign matter, solid-liquid separation, etc.

-

Chemical catalyst vibrating screen

Chemical catalyst vibratinACg screen is a device specially used for screening and grading chemical catalyst...

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Nylon sieve

Nylon sieve is a common screening tool, widely used in laboratories and industrial production, mainly used for screening...

-

Drying sand vibrating screen

Drying sand vibrating screen is a vibrating screening device specially used for screening dried sand. It is mainly...

-

Herbal vibrating screen

Herbal vibrating screen is a device for screening, grading and removing impurities from herbal materials. It is commonly...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.