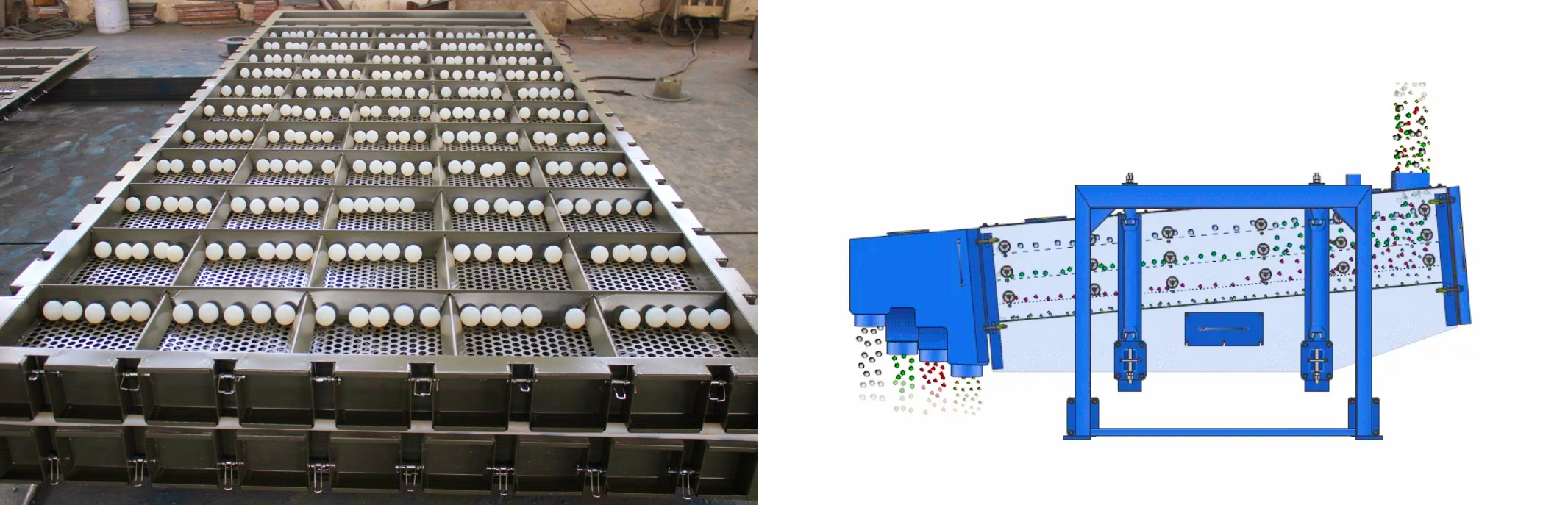

Plastic granules square swing screen

Plastic granules square swing screen is a low-speed, high-precision vibration screening device specially designed for grading and removing impurities from plastic granules. Its core feature is that its movement mode combines vibrations in three directions: horizontal, vertical and throwing, so that the plastic granules can be fully dispersed, layered and separated on the screen surface. The plastic granule square swing screen is of great significance in ensuring the uniformity of the size of plastic granules, removing foreign matter and impurities, and improving product quality in the production, recycling, modification and granulation of plastic raw materials.

What is the working principle of plastic granules square swing screen?

Plastic granules square swing screen simulates the movement of artificial screening to make the material move in three dimensions on the screen surface, thereby achieving high-precision screening. Its gentle swinging motion reduces the damage of plastic granules and is suitable for screening various plastic granules.

Types of plastic granules square swing screen

Single-layer plastic granules square swing screen

Application scenario: Suitable for occasions with simple granules screening requirements, mainly used for screening plastic granules of a single specification, commonly seen in the initial screening process.

Applicable materials: coarse screening of plastic granules (such as PP, PE, etc.).

Double-layer plastic granules square swing screen

Application scenario: Suitable for screening requirements with a variety of granules specifications, suitable for medium-sized production scale, and can screen two types of granules size materials at the same time.

Applicable materials: grading and screening of plastic granules (such as PVC, ABS, etc.).

What are the advantages of plastic granules square swing screen?

Dealing with irregular plastic granules blocking holes and materials: Crushed plastics contain long strips and flaky impurities, which are easy to get stuck in square or round sieve holes. The trajectory of plastic granules square swing screen is a compound parabola, and the granules are subject to multi-dimensional acceleration, which promotes screening.

Solving the problem of low efficiency of multi-size classification of plastic granules: The single layer of plastic granules square swing screen can be equipped with up to 5 levels of screens to achieve multiple screens in one machine.

Dealing with the problem of high crushing rate of brittle plastic granules: Engineering plastics are easy to break in high-frequency vibration. Using dual motors in reverse synchronous drive, the vibration frequency is reduced to 800rpm, and the amplitude is increased to 8mm to reduce granules collision.

Static adsorption causes screen blockage: Plastic granules are prone to generate static electricity due to friction, and fine powder adheres to the screen, reducing the screening rate. Plastic granules square swing screen uses conductive materials or adds carbon powder coating to eliminate static electricity accumulation.

Recommended mesh size of plastic granules square swing screen

|

Plastic granule types |

Common particle size range (mm) |

Recommended sieve mesh size |

Application scenarios |

|

General plastic granules (PE, PP, PVC, etc.) |

1-5 |

10-40 |

Pelletizing production line, recycling |

|

Engineering plastic granules (ABS, PC, PA, etc.) |

0.5-3 |

20-60 |

Modified production, precision products |

|

Recycled plastic granules |

1-10 |

5-30 |

Recycling, coarse screening |

|

Plastic microbeads |

0.1-1 |

40-120 |

Cosmetics, medical devices |

|

Plastic powder |

<0.1 |

120-325 |

Coatings, 3D printing |

What is the application of plastic granule square swing screen?

Plastic granulation production line: Plastic granules may have problems such as uneven particle size, dust or impurities. Plastic granules square swing screen is used to accurately screen these plastic granules and remove unqualified granules.

Plastic recycling: After the recycled waste plastics are pre-treated by crushing, cleaning, etc., they need to be screened to remove impurities and plastics of different particle sizes. Plastic granules square swing screen can efficiently classify recycled plastics.

Plastic modification production: Additives are mixed with plastic raw materials and granulated through processes such as extrusion. Plastic granules square swing screen is used to screen the modified plastic granules and remove agglomerated or unqualified granules.

Plastic powder screening: Plastic powder is produced during plastic processing, and these powders can be used to produce certain special products. Plastic granules square swing screen is used to screen plastic powder to meet different mesh requirements.

Plastic granules square swing screen is widely used in the production, recycling, modification and other links of plastic granules. It can improve product quality and production efficiency, and is an indispensable equipment in the plastic industry.

-

Potato Starch Vibrating Screen

Granules, powders, and paddle materials can be used.

-

Screening black soldier fly feces and larvae can separate the worms and feces, saving labor.

-

Ensures removal of contaminants such as large particles and agglomerates from metal powders, providing accurate particle size distribution

-

Remove solids from liquid slurries and recover valuable materials in the waste stream for reuse.

-

Tumbler screening machine for glass frits and glass granules

Tumbler screening machine for glass frits and glass granules generally refers to a drum-type screen...

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Nylon sieve

Nylon sieve is a common screening tool, widely used in laboratories and industrial production, mainly...

-

Drying sand vibrating screen

Drying sand vibrating screen is a vibrating screening device specially used for screening dried sand. It...

-

Vibrating screen for coal gangue screening

Vibrating screen for coal gangue screening is a kind of equipment specially used for grading and...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.