Graphene powder cyclone screen

Graphene powder cyclone screen is a commonly used equipment for graphene powder screening and grading. It uses airflow to assist material separation and screening, and is widely used in high-precision grading, clean screening and separation of ultrafine materials. As a nano-scale ultrafine material, graphene has unique characteristics such as ultra-lightness, electrostatic properties and agglomeration tendency. Due to its unique physical and chemical properties, it often needs to be processed under very fine grading conditions.

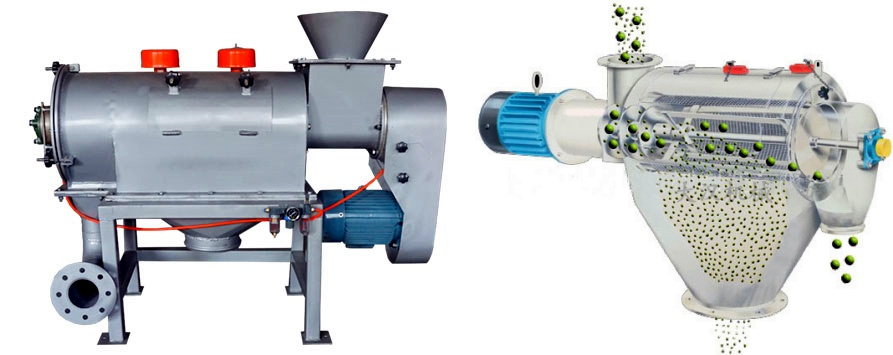

Video of graphene powder cyclone screen

How does the graphene powder cyclone screen work

Graphene powder cyclone screen separates graphene powder by particle size through a combination of high-speed rotating airflow and screen:

Airflow drive: Graphene powder enters the screening chamber through the feed port, and the airflow blows the graphene powder away and brings it into the rotating area.

Centrifugal separation: The rotating airflow generates centrifugal force, and larger graphene powder particles are thrown to the outside of the screen. Ultrafine graphene powder smaller than the screen hole passes through the screen and enters the collection device with the airflow.

Cyclone collection: Larger particles that do not pass through the screen are captured by the cyclone separator and settle in the collector below.

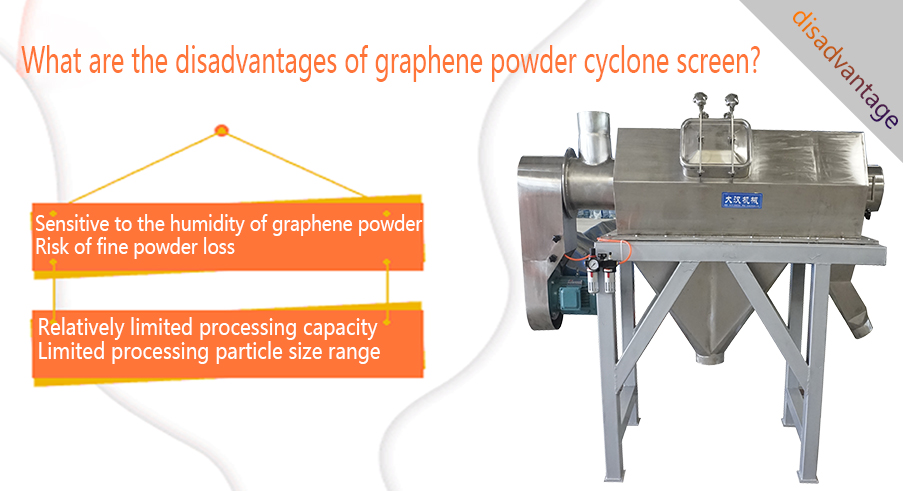

What are the disadvantages of graphene powder cyclone screen?

Sensitive to the humidity of graphene powder: Graphene powder cyclone screen relies on airflow to disperse materials. If the humidity of graphene powder is too high, it is easy to cause the material to adhere to the screen or the inner wall of the equipment, and may even cause equipment blockage.

Risk of fine powder loss: The screen relies on airflow to transport materials. Some ultrafine powders may escape in the airflow and are difficult to collect completely, causing material loss, affecting production efficiency and product quality.

Relatively limited processing capacity: For large-scale production needs, the processing capacity of a single device may be relatively small. If a large amount of graphene powder needs to be processed, multiple devices need to be operated in parallel.

Limited processing particle size range: It is suitable for ultrafine powders (<50μm), and the screening efficiency of larger particles (>100μm) or mixed particle size materials is low. It is not suitable for the situation where larger particles are mixed in graphene powder, and a pre-coarse screening device may be required.

Technical parameters of graphene powder cyclone screen

|

Parameter category |

Parameter name |

Typical parameter range |

|

Processing capacity |

Processing volume |

10-500kg/h |

|

Screening accuracy |

Screen aperture |

0.1-100μm |

|

Air flow velocity |

Air flow velocity |

10-50m/s |

|

Power consumption |

Motor power |

1.5-15kW |

|

Equipment size |

Dimensions (length×width×height) |

1.5m×1.2m×2.5m-3m×2m×4m |

|

Feeding method |

Feeding method |

Gravity feeding or pneumatic conveying |

|

Noise level |

Operation noise |

≤75 dB |

|

Applicable materials |

Applicable material types |

Graphene powder, nano powder, ultrafine powder, etc. |

|

Environmental requirements |

Working temperature |

-20℃ to 80℃ |

|

Humidity requirements |

Material humidity |

≤5% |

Application fields of graphene powder cyclone screen

Graphene production and research: Graphene powder cyclone screen is used to separate and screen graphene powders of different particle sizes to ensure the uniformity of the particle size of each batch of graphene powder.

Electronic materials industry: Graphene is widely used in supercapacitors, electronic devices, conductive materials and other fields. Graphene powder cyclone screen can ensure the screening of high-quality graphene powder to meet the needs of high-performance applications.

New energy industry: Graphene powder is used in new energy fields such as lithium batteries and hydrogen storage. High-precision screening helps to improve the conductivity and performance of graphene in batteries.

Coatings and inks industry: Graphene is a filler and modifier. It can be finely graded to ensure the uniformity and stability of coatings or inks.

Composite materials industry: Graphene composite materials require uniform particle distribution. It can separate graphene powder that does not meet the particle size requirements to ensure the stability and performance of the material.

Precautions for selecting graphene powder cyclone screen

Screen accuracy: Select the appropriate screen aperture to ensure that the particle size requirements of graphene powder can be met.

Airflow adjustment: The airflow velocity of the cyclone screen needs to be adjusted according to the powder characteristics of graphene to ensure the classification effect.

Material selection: Graphene powder has a certain degree of corrosiveness. Corrosion-resistant materials are selected to extend the service life of the equipment.

Graphene powder cyclone screen manufacturer

Dahan Machinery is a well-known manufacturer of vibrating screens and conveying equipment in China. Its standard product line usually focuses on solutions for materials such as food powder, grain, sand and minerals. The company produces a variety of graphene powder cyclone screens, with fineness as fine as 500 mesh. According to the material, it can be divided into stainless steel cyclone screens, carbon steel cyclone screens, plastic cyclone screens, etc.

As a powder processing equipment, the graphene powder cyclone screen has a precise classification ability that is directly related to the value realization of graphene materials in new energy, electronics and other fields, and is an indispensable key link in the industrialization process.

-

Potato Starch Vibrating Screen

Granules, powders, and paddle materials can be used.

-

Screening black soldier fly feces and larvae can separate the worms and feces, saving labor.

-

Ensures removal of contaminants such as large particles and agglomerates from metal powders, providing accurate particle size distribution

-

Remove solids from liquid slurries and recover valuable materials in the waste stream for reuse.

-

Plastic granules square swing screen

Plastic granules square swing screen is a device specially used for screening plastic granules. It is suitable for...

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Nylon sieve

Nylon sieve is a common screening tool, widely used in laboratories and industrial production, mainly...

-

Drying sand vibrating screen

Drying sand vibrating screen is a vibrating screening device specially used for screening dried sand. It...

-

Vibrating screen for coal gangue screening

Vibrating screen for coal gangue screening is a kind of equipment specially used for grading and...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.