Tumbler Screening Machine for Glass Frits and Glass Graules

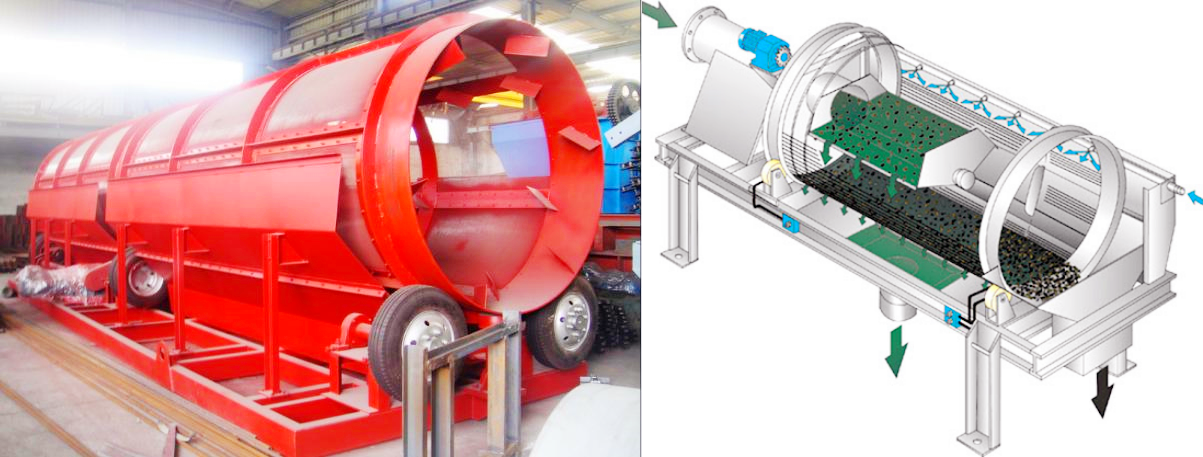

Tumbler screening machine for glass frits and glass granules generally refers to a drum-type screening equipment used to screen and classify glass frit (a block formed by cooling glass raw materials after high-temperature melting) or glass granules. This equipment is widely used in glass manufacturing, recycling or processing industries, and can classify particles according to their size.

Video of tumbler screening machine for glass frits and glass granules

How does the tumbler screening machine for glass frits and glass granules work

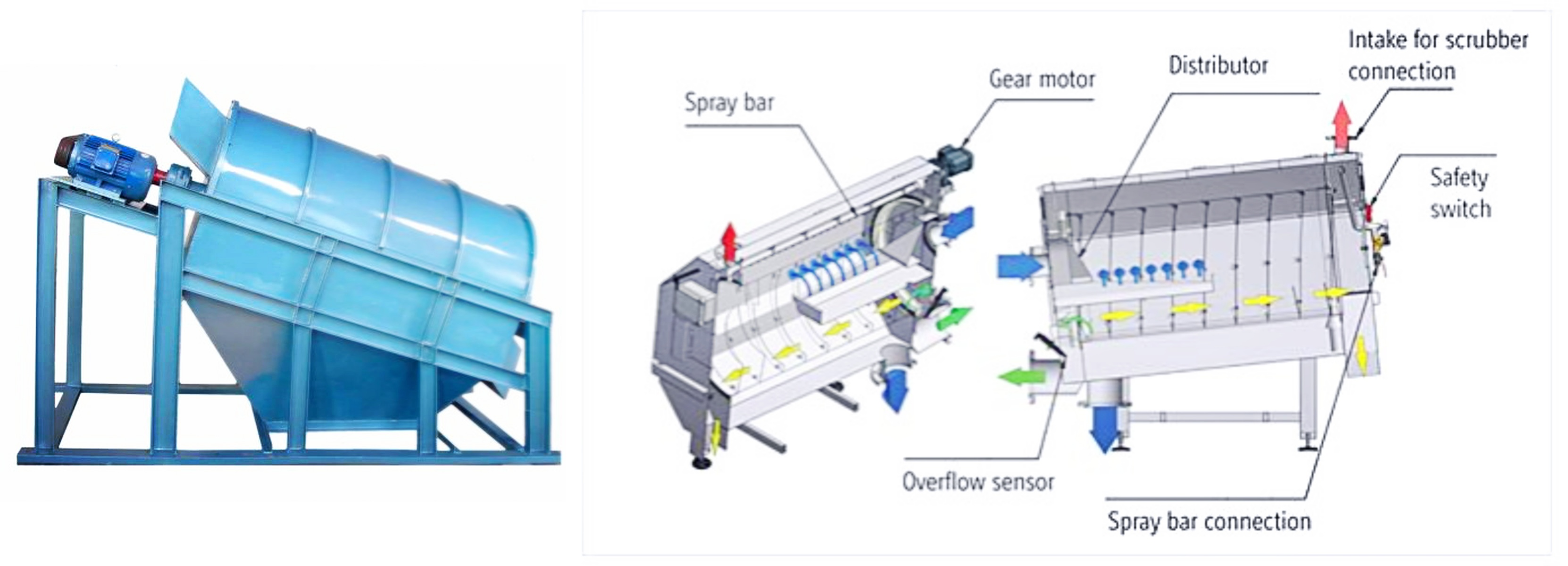

①Drum rotation: the material enters the rotating drum from the feed port, and the inner wall of the drum is equipped with a screen.

②Screening process: the material rotates with the drum, and particles smaller than the screen hole pass through the screen, while those larger than the screen hole continue to move forward and are finally discharged from the discharge port.

Main structure of tumbler screening machine for glass frits and glass granules

Drum: core component, usually made of wear-resistant material, with screens of different apertures inside.

Drive device: motor and reducer drive the drum to rotate.

Bracket: supports the drum and drive device.

Feed port and discharge port: used for material entry and discharge respectively.

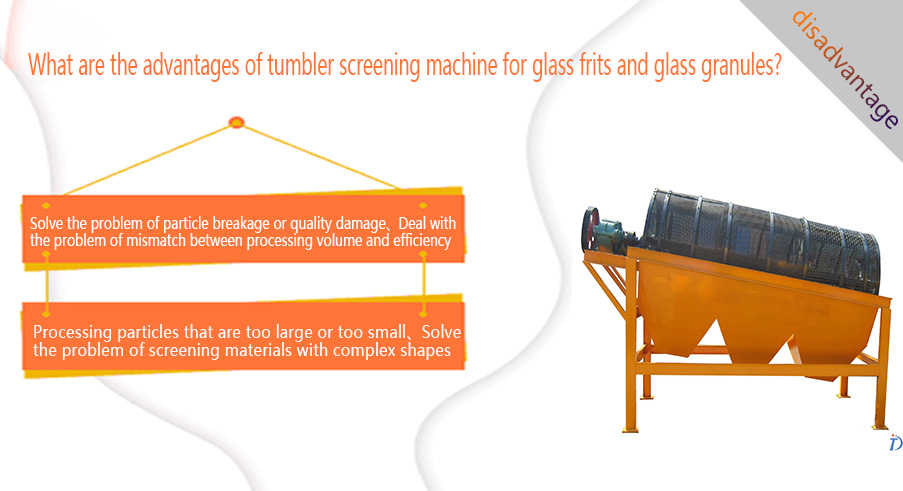

What are the advantages of tumbler screening machine for glass frits and glass granules?

1. Solve the problem of particle breakage or quality damage: The rotation of the drum or the collision of particles may cause the glass particles to break further, affecting subsequent use. Reduce the drum speed to reduce the impact force between particles. Optimize the feeding method to avoid putting too much material at one time.

2. Deal with the problem of mismatch between processing volume and efficiency: When the material processing volume is too large, the drum may be overloaded, resulting in incomplete screening or equipment failure. Select a drum with a suitable diameter and length according to actual needs to increase the screening area.

3. Processing particles that are too large or too small: The size of glass frit and glass particles does not meet the requirements, which will affect the product quality. This can be solved by adjusting the vibration frequency and amplitude, replacing the appropriate screen or performing multiple screening.

4. Solve the problem of screening materials with complex shapes: Glass frits are irregular in shape and are easily stuck in the screen holes or the gap between the guide plates. Sheet glass is difficult to classify by particle size. Add a spiral guide plate in the drum to force the material to roll and change direction.

Recommended mesh number for tumbler screening machine for glass frits and glass granules

|

Glass particle size (mm) |

Corresponding mesh number (Mesh) |

Applicable scenarios |

|

>50mm |

5 mesh or less (≤5 Mesh) |

Preliminary screening of large glass frits |

|

10-50mm |

5-16 mesh (5-16 Mesh) |

Architectural glass recycling, glass frit sorting |

|

5-10mm |

16-35 mesh (16-35 Mesh) |

Glass recycling, glass sand production |

|

1-5mm |

35-60 mesh (35-60 Mesh) |

Fine screening, suitable for glass micro powder preparation |

|

<1mm |

60-100 mesh (60-100 Mesh) |

Ultra-fine glass powder, suitable for ceramics, coatings and other industries |

Application of tumbler screening machine for glass frits and glass granules

1. Waste glass recycling and processing line: mixed waste glass needs to separate impurities and graded recycling. Tumbler screening machine for glass frits and glass granules can separate super large frit (>10cm) and non-glass impurities such as metal and ceramics.

2. Preparation of raw materials for glass products: glass frit needs to be crushed and screened into a specific particle size for use in the furnace. Tumbler screening machine for glass frits and glass granules separates incompletely crushed frit (>5cm) and qualified particles (<3cm) through multiple layers of screens.

3. Photovoltaic glass manufacturing: Photovoltaic glass requires high-purity and uniformly sized glass particles as substrate raw materials. The drum screening machine can be combined with ultrasonic vibration to remove impurities and screen ultrafine glass powder (<0.1mm).

4. Construction glass sand production: waste glass is processed into construction sand (instead of natural river sand). Tumbler screening machine for glass frits and glass granules uses a double-layer drum screen (20 mesh + 40 mesh) to separate 20-40 mesh (0.4-0.8mm) glass sand.

If you need a specific model of drum screening machine, or want to know the price and technical parameters, you can tell the customer service what you need, we will provide you with detailed information and make a quotation.

-

Potato Starch Vibrating Screen

Granules, powders, and paddle materials can be used.

-

Screening black soldier fly feces and larvae can separate the worms and feces, saving labor.

-

Ensures removal of contaminants such as large particles and agglomerates from metal powders, providing accurate particle size distribution

-

Remove solids from liquid slurries and recover valuable materials in the waste stream for reuse.

-

Desert sand sieving machine

Desert sand sieving machine is a mechanical equipment used for sand and gravel processing or sieving...

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Nylon sieve

Nylon sieve is a common screening tool, widely used in laboratories and industrial production, mainly...

-

Drying sand vibrating screen

Drying sand vibrating screen is a vibrating screening device specially used for screening dried sand. It...

-

Vibrating screen for coal gangue screening

Vibrating screen for coal gangue screening is a kind of equipment specially used for grading and...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.