Small vibrating screener

Small vibrating screener is a kind of equipment used for screening and grading granular materials. It uses the exciting force generated by the vibration motor to make the screen produce high-frequency vibration, thereby realizing the screening and transportation of materials. It is mainly used for screening and conveying granular and powdery materials, such as materials in the food, chemical, pharmaceutical, mining and other industries. It can also be used in laboratories, small production lines and occasions that require fine screening.

Video of small vibrating screener

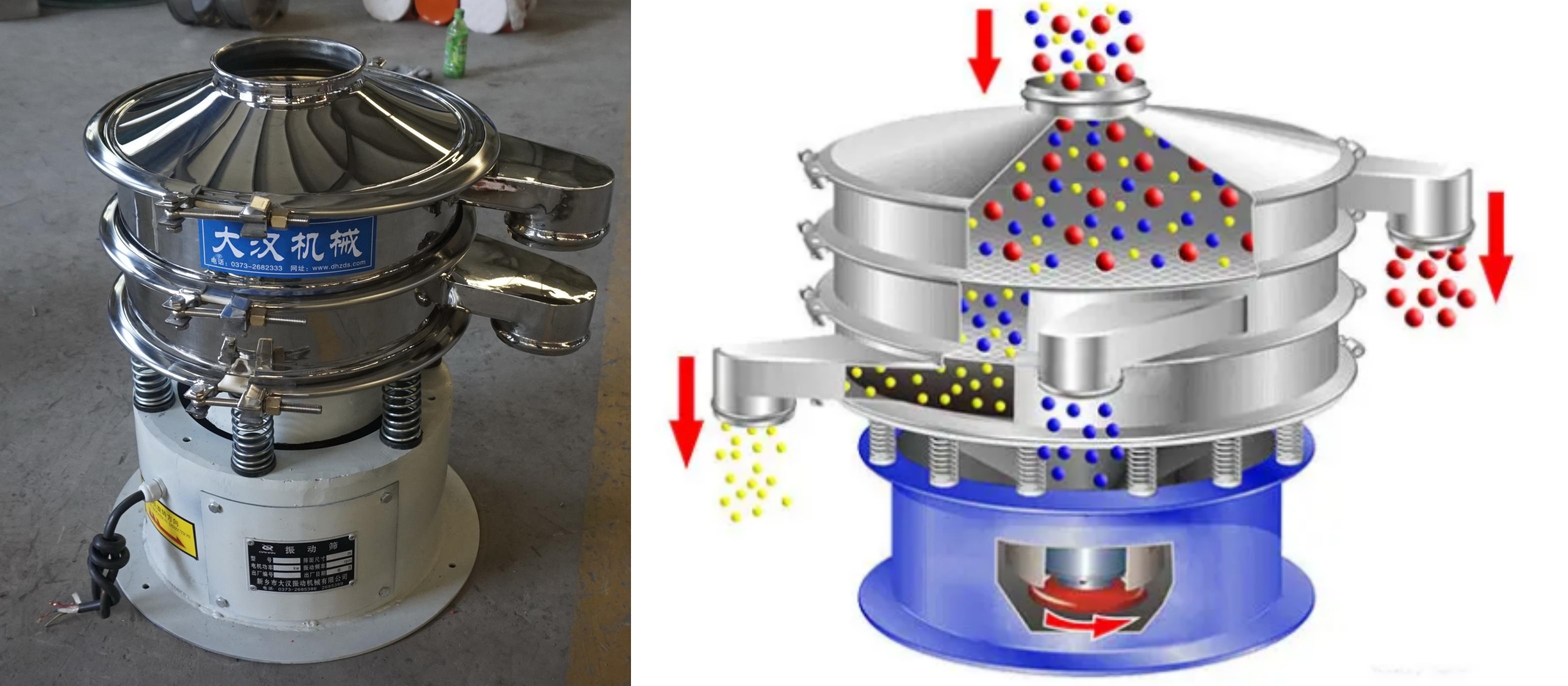

How does the small vibrating screener work?

Vibration source: The vibration motor generates high-frequency vibration, which is transmitted to the screen frame and screen.

Particle movement: The material moves on the screen under the action of vibration, and particles smaller than the screen aperture pass through the screen, while particles larger than the screen aperture remain on the screen.

Grading collection: Through the combination of multiple layers of screens, materials can be graded and collected according to different particle size ranges.

What are the disadvantages of small vibrating screening screeners?

1. Limited processing capacity: The screen surface size of a small vibrating screener is usually small, generally between 0.5 square meters and 2 square meters. Compared with large screening equipment, the amount of material that can be processed per unit time is much less. For example, in some small ore processing plants, a small vibrating screener is used for ore screening, and the processing capacity per hour may be only 1-5 tons, while a large screening machine can process tens or even hundreds of tons per hour.

2. Screening leakage and mixed level phenomenon are prone to occur: The vibration intensity and stability of a small vibrating screener are relatively weak. During the screening process, the material may not be able to fully contact the screen, resulting in some particles that should have been screened out failing to pass through the screen holes in time, or some particles may be mixed into other particle size levels due to uneven vibration.

3. More manual intervention: Most small vibrating screeners require manual operation in the feeding, discharging and screen cleaning links, and the degree of automation is not high. For example, when feeding, it is necessary to manually control the feeding speed and feeding amount, and when discharging, it is also necessary to manually collect and carry materials of different particle sizes, which not only increases labor costs, but also easily leads to irregular operations due to human factors, affecting the screening effect.

4. Easily affected by material characteristics: When dealing with sticky, moist or poorly fluid materials, the screening effect of small vibrating screening screeners will be greatly affected, and it may even cause the material to block the screen and the screening cannot be carried out normally. For example, when dealing with moist soil or sticky food raw materials, the material is easy to adhere to the screen, reducing the screening efficiency and affecting the normal operation of the equipment.

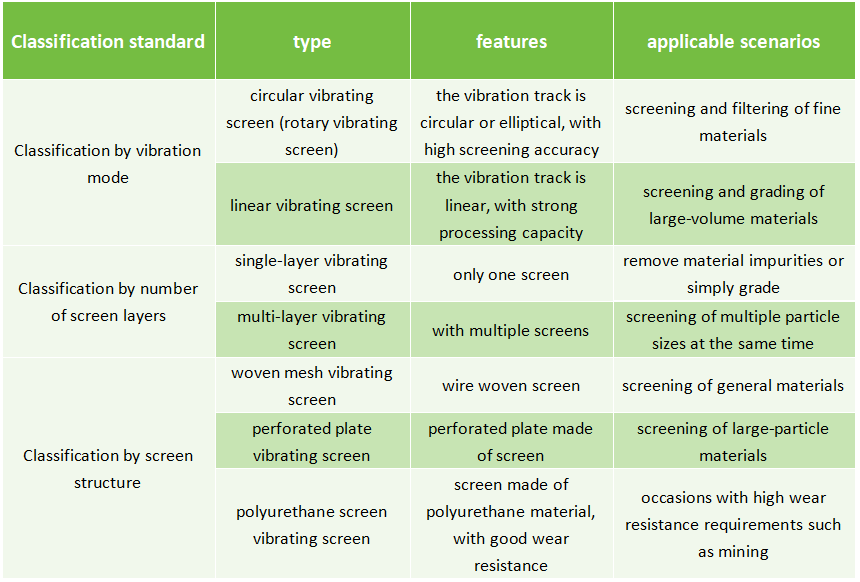

What are the different types of small vibrating screener?

What is a small vibrating screener used for?

1. Chemical industry: Grading the particle size of various chemical raw material powders or particles, such as calcium carbonate, to ensure the uniformity of the raw material particle size. Screen the finished products to remove impurities and particles that do not meet the particle size requirements and improve product quality. In the production of plastic particles, the particles that are too large or too small are removed by screening to make the particle size of the plastic particles consistent, which is conducive to subsequent processing and molding.

2. Food industry: Screening of grains such as wheat and rice to remove impurities, broken grains and foreign matter, improve the quality and purity of grains, and ensure the quality of food raw materials. In the production of powdered seasonings such as chili powder and pepper powder, the particle size of the seasoning is controlled by screening to make it taste more delicate and uniform, while removing possible impurities to ensure food safety.

3.Pharmaceutical industry: Screening of powdered materials such as pharmaceutical intermediates and raw materials to ensure that the particle size of the pharmaceutical raw materials meets the production requirements, which is conducive to the dissolution and absorption of the drugs and ensures the efficacy of the drugs. In the production of granules, capsules and other drugs, the prepared particles are screened to make the particle size uniform and ensure the accuracy and stability of the drug dosage.

4. Electronics industry: high-precision screening of powder materials such as ceramic powder and metal powder in the production process of electronic components to ensure that the powder particle size meets the requirements of electronic component manufacturing and improve the performance and reliability of electronic components.

5. Scientific research field: in the laboratory, it is used to perform particle size analysis and screening of various experimental samples, provide accurate sample particle size data for scientific research, help researchers understand the physical and chemical properties of samples, and promote the progress of scientific research projects.

What size small vibrating screener do I Need?

Why do you need a small vibrating screener?

Facilitate experiments and research and development: In scientific research institutions and laboratories, screening experiments and research on various materials are required to explore new processes, formulas or product performance. Small vibrating screeners can simulate the screening process in actual production, provide accurate experimental data and references for scientific researchers, and contribute to the development of new products and technological innovation.

Supplement and assist large-scale equipment: In some large production lines, there may be certain links that require additional screening or fine processing of a small amount of materials. At this time, small vibrating screeners can be used as a supplement and auxiliary tool for large-scale equipment to perform targeted screening of specific materials and improve the flexibility and adaptability of the entire production system.

Reduce the risk of cross-contamination of materials: For some production processes that require extremely high material purity and cleanliness, such as pharmaceutical production, high-end electronic material manufacturing, etc., the use of small vibrating screeners can be specifically targeted at single materials or small batches of materials for screening, reducing the risk of cross-contamination between different materials and ensuring the purity and quality stability of the product.

Why should you choose small vibrating screener?

1. Applicability: Small vibrating screeners are suitable for laboratories, research institutions and small-scale production environments, and can meet the particle processing needs in these scenarios.

2. Flexibility: Small vibrating screeners are usually small in size, simple in structure, easy to move and install, and highly flexible, suitable for places with limited space or frequent movement.

3. Cost-effectiveness: Compared with large vibrating screeners, small vibrating screeners are usually cheaper and more suitable for laboratories or small-scale production environments with limited budgets.

4. Accuracy: Small vibrating screeners can provide precise particle control, can finely screen and grade particles, and meet the requirements for particle size and distribution in experiments and production.

Small vibrating screeners are efficient, accurate and portable particle material screening equipment, widely used in laboratories, food, medicine, chemical industry and metallurgy. Selecting the appropriate screen aperture, vibration frequency and material, and regular maintenance and maintenance can ensure the long-term stable operation of the equipment.

-

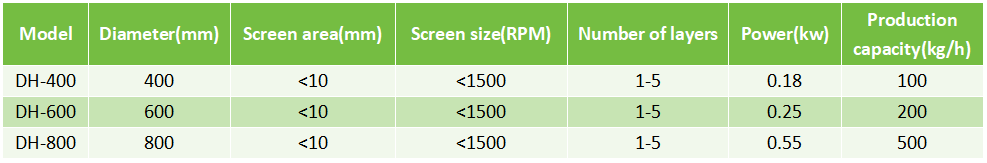

The model of vibration sieve is divided into eight equipments with different dimensions from 400-2000mm.

-

Sieve machine is a general-purpose vibrating screening and filtering equipment. The main material is divided into SUS304 stainless steel or Q235A carbon steel.

-

For safe sieving and precise grading of liquids, powders and granules, suitable for plants and factories that need to handle large volumes of products

-

For separation of different particle sizes in the same product, safe screening to eliminate foreign matter, solid-liquid separation, etc.

-

Chemical catalyst vibrating screen

Chemical catalyst vibratinACg screen is a device specially used for screening and grading chemical catalyst...

-

63 filter screen

63 filter screen usually refers to a filter screen with a pore size of 63 microns (µm). 63 microns refers to the size...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Nylon sieve

Nylon sieve is a common screening tool, widely used in laboratories and industrial production, mainly used for screening...

-

Drying sand vibrating screen

Drying sand vibrating screen is a vibrating screening device specially used for screening dried sand. It is mainly...

-

Stone powder vibrating screen

Drying sand vibrating screen is a screening device that uses the exciting force generated by the vibrating motor to...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.