Vibrating screen for ammonium sulfate screening

Vibrating screen for ammonium sulfate screening is a kind of equipment specially used for screening ammonium sulfate. Through vibration and screening, it effectively solves the problems of particle size classification, impurity removal and quality control in ammonium sulfate screening. It is widely used in fertilizer production, industrial applications, feed additives and laboratory testing, etc., which significantly improves product quality and production efficiency.

Video of vibrating screen for ammonium sulfate screening

How does the vibrating screen for ammonium sulfate screening work

The working principle of vibrating screen for ammonium sulfate screening is mainly based on the exciting force generated by the vibration motor, which makes the screen body vibrate at high frequency. The material is subjected to the vibration force on the screen surface, generating a throwing motion, thereby achieving grading and screening. The specific process is as follows:

1. Feeding: The ammonium sulfate particles or powder are evenly fed into the screen surface through the feeding device.

2. Screening: The material is subjected to the vibration force on the screen surface, and the particles or powder smaller than the screen mesh aperture fall through the screen to form the undersize; the particles larger than the screen mesh aperture remain on the screen surface to form the oversize.

3. Discharging: The oversize and undersize are discharged through their respective discharge ports to complete the screening process.

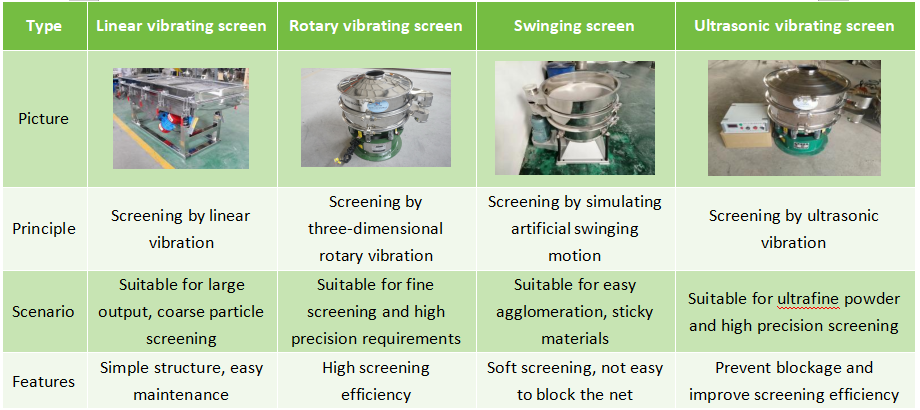

What types of vibrating screens are there for ammonium sulfate screening?

What are the advantages of the vibrating screen for ammonium sulfate screening?

1. Meet the screening accuracy requirements of ammonium sulfate: According to the particle size requirements of ammonium sulfate, select the appropriate mesh number and aperture to achieve accurate particle size classification. The ammonium sulfate screening swing screen has high screening accuracy and can better meet the ammonium sulfate screening with high requirements for screening accuracy.

2. Solve the uneven particle size distribution of ammonium sulfate: The particle size distribution of ammonium sulfate may be wide, containing particles of different sizes, which increases the difficulty of screening. The ammonium sulfate screening multi-layer vibrating screen can simultaneously grade multiple particle sizes and improve screening efficiency.

3. Solve the corrosive problem of ammonium sulfate: The contact material part of vibrating screen for ammonium sulfate screening is made of corrosion-resistant materials such as stainless steel and polypropylene, which can effectively resist the corrosion of ammonium sulfate. Anti-corrosion coating is applied to key components to further improve the corrosion resistance of the equipment.

4. Solve the problem of ammonium sulfate agglomeration: Vibrating screen for ammonium sulfate screening can effectively break up the agglomerated ammonium sulfate through high-frequency vibration, restore it to a loose state, and pass through the screen smoothly. Appropriate vibration parameters can be adjusted according to the agglomeration degree of ammonium sulfate to achieve the best breaking effect.

Recommended mesh number of vibrating screen for ammonium sulfate screening

Agricultural fertilizer: coarse-grained fertilizer is used for direct fertilization, with a mesh range of 4-20 mesh. Fine-grained fertilizer is used for certain special purposes or mixed fertilizers, with a mesh range of 20-60 mesh.

Chemical industry: used as chemical reagents, catalysts, etc., with high requirements for particle size, and fine screening may be required. The recommended screening mesh range is 60-200 mesh or higher.

Textile industry: used as flame retardants, etc., with moderate requirements for particle size. The recommended screening mesh range is 40-100 mesh.

Food industry: used as food additives, with strict requirements for particle size, and fine screening is required. The recommended screening mesh range is 80-325 mesh or higher.

Application scenarios of vibrating screen for ammonium sulfate screening

1. Fertilizer production plant:

① Primary screening after granulation: After ammonium sulfate granulation is completed, the particle size is uneven and there may be agglomerates. The ammonium sulfate screening vibrating screen makes the ammonium sulfate particles jump and roll violently on the screen surface. This can quickly separate larger agglomerates and particles that obviously do not meet the particle size requirements, providing relatively uniform materials for subsequent fine screening.

② Fine screening before finished product packaging: Before ammonium sulfate is packaged, vibrating screen for ammonium sulfate screening vibrates to evenly distribute the material on the screen surface, accurately screen out ammonium sulfate particles that meet a specific particle size range, and ensure consistent product particle size.

③ Auxiliary screening during drying: Ammonium sulfate may agglomerate due to high water content before drying. vibrating screen for ammonium sulfate screening can be pre-screened before drying to break up the agglomerates, so that the ammonium sulfate is heated more evenly during drying, and the drying efficiency and effect are improved. Installing a vibrating screen inside or at the outlet of the drying equipment can screen out agglomerates or insufficiently dried particles generated during the drying process in real time.

2. Warehousing and logistics: Ammonium sulfate in the warehouse is prone to agglomeration due to humidity and storage time. In large ammonium sulfate warehouses, random screening is performed every month to deal with agglomeration in a timely manner to ensure the quality of outbound products. The bumpy transportation when ammonium sulfate is transferred from the warehouse to the sales point may cause agglomeration or particle size changes in ammonium sulfate.

3. Quality inspection agency: In a professional ammonium sulfate quality inspection laboratory, researchers and quality inspectors use small, high-precision vibrating screens to screen and analyze ammonium sulfate samples. In order to evaluate the performance of ammonium sulfate in actual use scenarios, quality inspection agencies use vibrating screens to simulate screening conditions in various environments.

When choosing an vibrating screen for ammonium sulfate screening, it is recommended to consult a professional vibrating screen supplier and make a selection based on specific production needs and material characteristics.

-

Potato Starch Vibrating Screen

Granules, powders, and paddle materials can be used.

-

Screening black soldier fly feces and larvae can separate the worms and feces, saving labor.

-

Ensures removal of contaminants such as large particles and agglomerates from metal powders, providing accurate particle size distribution

-

Remove solids from liquid slurries and recover valuable materials in the waste stream for reuse.

-

Vibrating screen for phosphate ore screening

Vibrating screen for phosphate ore screening is a kind of vibrating mechanical equipment specially used for...

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Nylon sieve

Nylon sieve is a common screening tool, widely used in laboratories and industrial production, mainly used for screening...

-

Drying sand vibrating screen

Drying sand vibrating screen is a vibrating screening device specially used for screening dried sand. It is mainly...

-

Stone powder vibrating screen

Drying sand vibrating screen is a screening device that uses the exciting force generated by the vibrating motor to...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.