Vibrating screen for phosphate ore screening

Vibrating screen for phosphate ore screening is a kind of vibrating mechanical equipment specially used for screening and grading phosphate ore materials. Its main function is to use the principle of vibration to make the phosphate ore materials jump, loosen and stratify on the screen surface, so as to achieve grading according to particle size, so as to obtain products of different particle sizes to meet the needs of subsequent processing or sales.

Vibrating screen for phosphate ore screening video

Working principle of vibrating screen for phosphate ore screening

1. Generation of excitation force: Usually two motors rotate in opposite directions synchronously, so that the exciter generates a strong reverse excitation force. For example, a circular vibrating screen uses a vibration motor to excite materials to throw up the material on the screen surface.

2. Material movement: After the phosphate rock is transported to the screen surface of the vibrating screen, under the action of the exciting force, the material is subject to the force of periodic forward projection. Because phosphate rock particles of different sizes are affected by different excitation forces and their own gravity, their movement trajectories and speeds are different.

3. Screening implementation: Phosphate rock particles with a particle size smaller than the screen hole can pass through the pores of the screen and fall into the collection device below; phosphate rock particles with larger particle sizes are blocked on the screen. As the screen vibrates, they gradually move toward the discharge port and are finally discharged from the screen machine, thereby achieving the separation of phosphate rocks of different particle sizes.

Recommended mesh sizes for vibrating screen for phosphate ore screening

Pre-screening before coarse crushing: At this stage, a screen of about 4 mesh to 10 mesh is generally selected, and the corresponding mesh size is 4.75mm-2.00mm.

Grading after crushing

①After medium crushing: usually choose 10 mesh-30 mesh, mesh size 2.00mm-0.600mm.

②After fine crushing: 20 mesh to 60 mesh may be used, and the mesh size is 0.850mm to 0.250mm.

③Classification after grinding: Generally, 80 mesh-200 mesh is used, and the mesh size is 0.180mm-0.075mm.

Screening before product packaging: usually 100 mesh-150 mesh, mesh size 0.150mm-0.106mm.

What are the shortcomings of vibrating screens for phosphate ore screening?

1、Limited screening effect on fine particles: Although vibrating screen for phosphate ore screening has a good screening effect on phosphate ore of general particle size, for extremely fine particles (such as less than 0.075mm), the screening efficiency and accuracy may decrease due to the agglomeration between particles and the increased possibility of sieve hole clogging.

2、Large investment in supporting facilities: In order to ensure the normal operation of vibrating screen for phosphate ore screening, it is necessary to equip the corresponding feeding equipment, conveying equipment, etc. The investment in these supporting facilities is also relatively large, which further increases the investment cost of the overall project.

3、There are limitations in handling sticky materials: When the phosphate ore is more humid or sticky, although vibrating screen for phosphate ore screening has a certain self-cleaning ability, the material may still adhere to the screen, resulting in reduced screening efficiency. Compared with some vibrating screens with special anti-sticking designs, its adaptability in handling highly sticky materials is relatively weak.

4、High initial investment cost: Vibrating screens for phosphate ore screening are usually large in structure, have high manufacturing process requirements, and need to be equipped with high-performance exciters, motors and other components, so the purchase price of the equipment is relatively high.

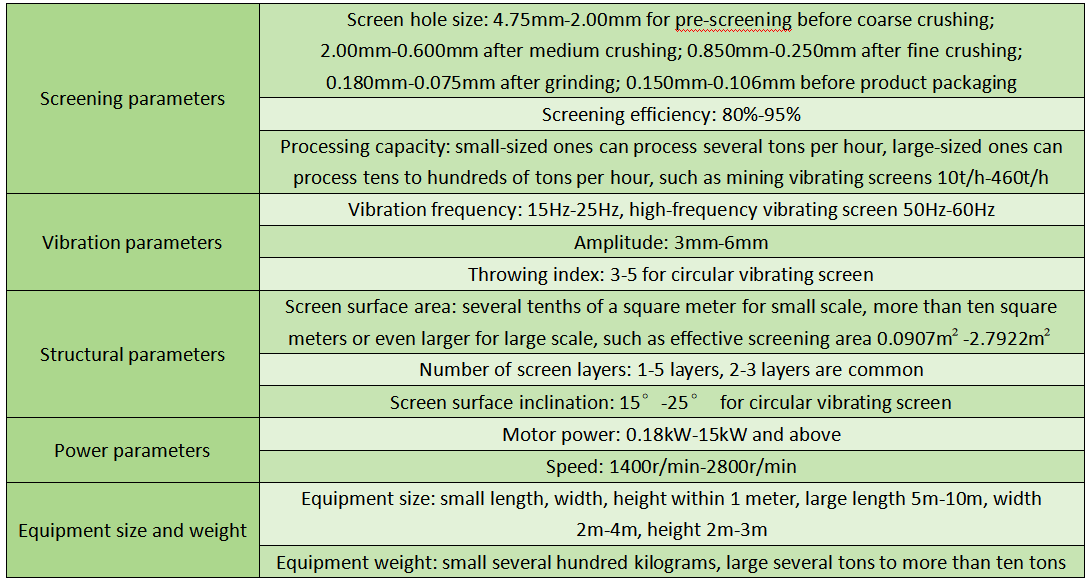

What are the parameters of a vibrating screen for phosphate ore screening?

Application of vibrating screens for phosphate ore screening

1. Phosphate mining: The newly mined phosphate ore is of different sizes and is mixed with a large amount of impurities such as soil. Vibrating screen for phosphate ore screening can pre-screen the raw ore before the coarse crushing equipment, screen out the phosphate ore particles with smaller particle size that meet the requirements of subsequent processing, and directly enter the next process, while separating the ore and impurities with larger particle size and sending them to the coarse crushing equipment for crushing.

2. Phosphate beneficiation: After the phosphate ore is crushed in multiple stages such as coarse crushing, medium crushing and fine crushing, it needs to be graded and screened to obtain phosphate ore particles of different particle size ranges to provide suitable feed for subsequent grinding operations. Vibrating screen for phosphate ore screening can accurately grade the crushed phosphate ore according to the feeding requirements of the grinding equipment, so that the particle size of the material entering the grinding machine is more uniform.

3. Phosphate processing: After the phosphate ore is ground, it needs to be divided into different particle size levels through a screening vibrating screen to meet the requirements of the production of different phosphorus chemical products. After phosphate ore is processed into final products, such as phosphate fertilizer, phosphate concentrate, etc., it needs to be screened before packaging to remove possible agglomerates or oversized particles to ensure the uniformity of the product's particle size and appearance quality.

4. Recycling and reuse of phosphate ore: During the processing of phosphate ore, some wastes such as tailings and slag will be generated. Vibrating screen for phosphate ore screening can screen these wastes, separate the underutilized phosphate ore particles that may remain, and recycle and reprocess them to improve the utilization rate of phosphate ore resources.

Vibrating screen for phosphate ore screening is a highly reliable screening equipment that plays an important role in the phosphate ore beneficiation process. By reasonably selecting and using the vibrating screen, the screening efficiency and processing capacity of phosphate ore can be improved, creating favorable conditions for subsequent sorting operations.

-

The model of vibration sieve is divided into eight equipments with different dimensions from 400-2000mm.

-

Sieve machine is a general-purpose vibrating screening and filtering equipment. The main material is divided into SUS304 stainless steel or Q235A carbon steel.

-

For safe sieving and precise grading of liquids, powders and granules, suitable for plants and factories that need to handle large volumes of products

-

For separation of different particle sizes in the same product, safe screening to eliminate foreign matter, solid-liquid separation, etc.

-

Chemical catalyst vibrating screen

Chemical catalyst vibratinACg screen is a device specially used for screening and grading chemical catalyst...

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Nylon sieve

Nylon sieve is a common screening tool, widely used in laboratories and industrial production, mainly used for screening...

-

Drying sand vibrating screen

Drying sand vibrating screen is a vibrating screening device specially used for screening dried sand. It is mainly...

-

Stone powder vibrating screen

Drying sand vibrating screen is a screening device that uses the exciting force generated by the vibrating motor to...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.