Vibrating screen for chemical powder screening

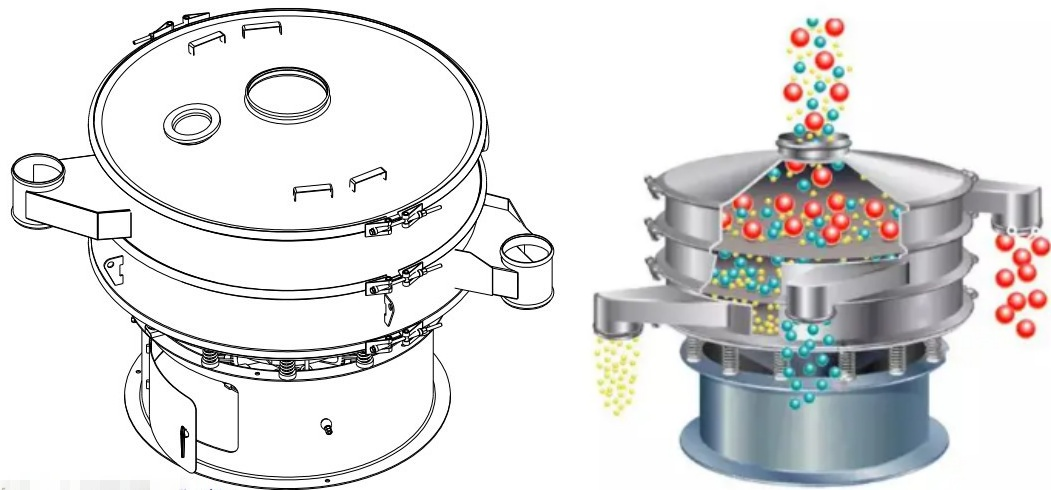

Vibrating screen for chemical powder screening refers to the equipment used in the chemical industry to screen, grade or remove impurities from chemical powders by using vibration screen. It makes the powder evenly distributed on the screen surface through vibration, and separates powders of different specifications according to particle size, thereby achieving the screening effect. It can be widely used in the production, processing and quality control of chemical powders.

Video of vibrating screen for chemical powder screening

What is the principle of vibrating screen for chemical powder screening?

① Vibrating screen for chemical powder screening uses the exciting force generated by the vibration motor to make the material on the screen surface move in a jumping manner.

② Chemical powders of different particle sizes pass through the holes of the screen on the screen surface to achieve stratification and separation.

③ The screening effect can be controlled by adjusting the vibration frequency, amplitude and screen specifications.

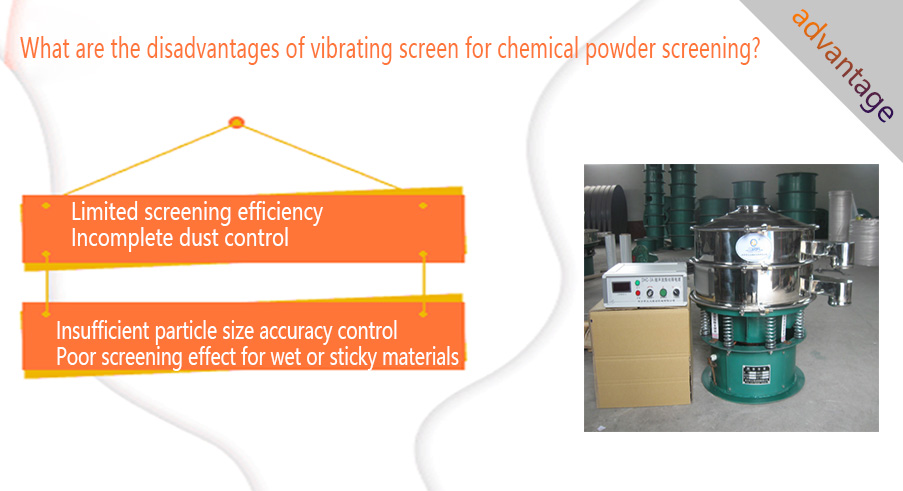

What are the disadvantages of vibrating screen for chemical powder screening?

1. Limited screening efficiency: For ultrafine powders (such as less than 20 microns) or large batches of materials, the processing capacity of vibrating screen for chemical powder screening may be insufficient, resulting in long screening time or low output. The screen aperture is too small and easy to clog, and the vibration force is difficult to evenly distribute to the large screen surface.

2. Incomplete dust control: Even with a sealing cover and a dust collector, ultrafine powders may still leak a small amount of dust during screening, especially at the equipment connection or after long-term operation. The seal is aged. The movement of the chemical powder screening vibrating screen will produce tiny gaps, making it difficult to achieve 100% sealing.

3. Insufficient particle size accuracy control: For chemical powders that require extremely high particle size consistency, a small amount of oversized or undersized particles may be mixed into the vibrating screen. The screen aperture distribution is not uniform enough, and the material may jump or accumulate during the vibration process, affecting the classification accuracy.

4. Poor screening effect for wet or sticky materials: When the chemical powder has high humidity or contains sticky components, the powder is easy to adhere to the surface of the screen, resulting in a significant decrease in screening efficiency. Particles of wet or sticky materials tend to gather together to form lumps, blocking the screen or reducing the material passing rate.

Recommended mesh number of chemical powder screening vibrating screen

Coarse screen: 20-60 mesh, suitable for separation of coarse particles, such as preliminary screening of certain chemical raw materials.

Medium screen: 80-200 mesh, suitable for screening of most chemical powders, such as pigments, dyes, etc.

Fine screen: 200-400 mesh, suitable for screening of fine powders, such as pharmaceutical powders, ultrafine pigments, etc.

Ultrafine screen: above 400 mesh, suitable for screening of ultrafine powders, such as nanomaterials, ultrafine catalysts, etc.

Application of vibrating screen for chemical powder screening

1. Fine chemical industry: In the production process of pigments and dyes, the powder needs to be precisely controlled in particle size. It is also used to grade catalyst powder and pesticide powder to ensure that its particle size distribution meets the requirements.

2. Inorganic chemical industry: Vibrating screen for chemical powder screening is used for grading calcium carbonate powder, screening alumina powder, etc., to remove impurities and coarse particles and obtain products of different particle sizes.

3. Organic chemical industry: Vibrating screen for chemical powder screening is used to screen plastics, resin powder, rubber powder, drug powder, etc., remove impurities and coarse particles, and improve product quality.

4. Fertilizer industry: The particle size of fertilizer will affect its fertilization effect. Vibrating screen for chemical powder screening is used in fertilizer production lines to control the size of fertilizer particles so that crops can better absorb them.

Precautions for vibrating screen for chemical powder screening

When using vibrating screen for chemical powder screening, it is very important to reasonably select the screen material and mesh number, adjust the vibration parameters, ensure uniform feeding, and regularly maintain and clean the equipment. Through scientific operation and maintenance, the screening efficiency can be maximized, the service life of the equipment can be extended, and the screening quality of the product can be ensured.

Vibrating screen for chemical powder screening plays an important role in the chemical industry. It can accurately separate chemical powders of different particle sizes to meet the needs of production and research.

-

Potato Starch Vibrating Screen

Granules, powders, and paddle materials can be used.

-

Screening black soldier fly feces and larvae can separate the worms and feces, saving labor.

-

Ensures removal of contaminants such as large particles and agglomerates from metal powders, providing accurate particle size distribution

-

Remove solids from liquid slurries and recover valuable materials in the waste stream for reuse.

-

Vibrating screen for metal powder screening

Metal powder screening is usually carried out using a vibrating screen. Vibrating screen for metal powder...

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Nylon sieve

Nylon sieve is a common screening tool, widely used in laboratories and industrial production, mainly used for screening...

-

Drying sand vibrating screen

Drying sand vibrating screen is a vibrating screening device specially used for screening dried sand. It is mainly...

-

Stone powder vibrating screen

Drying sand vibrating screen is a screening device that uses the exciting force generated by the vibrating motor to...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.