Vibrating screen for metal powder screening

Metal powder screening is usually carried out using a vibrating screen. Vibrating screen for metal powder screening is a commonly used screening equipment, suitable for screening and grading fine particles such as metal powder, which can improve production efficiency and product quality. The vibrating screen is used to screen and grade materials through the vibrating screen surface. For fine particles such as metal powder, the vibrating screen is very suitable for efficient screening operations.

Vibrating screen for metal powder screening video

How does the vibrating screen for metal powder screening work?

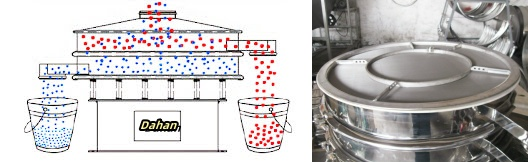

1. Vibrating screen for metal powder screening usually includes components such as a vibration motor, a screen, and a screen box. The vibration motor generates horizontal, vertical, or inclined vibrations to move and screen the metal powder on the screen.

2. The metal powder is screened on the vibrating screen by the vibration force generated by the vibrator. Smaller particles of metal powder will fall through the screen holes into the container below, while larger metal powder particles will be retained on the screen.

What types of vibrating screens for metal powder screening are there?

Weight and use classification:

① Mining vibrating screens: such as high-efficiency heavy-duty screens, self-centering vibrating screens, etc., but this type of screening machine is usually not used for fine metal powder screening.

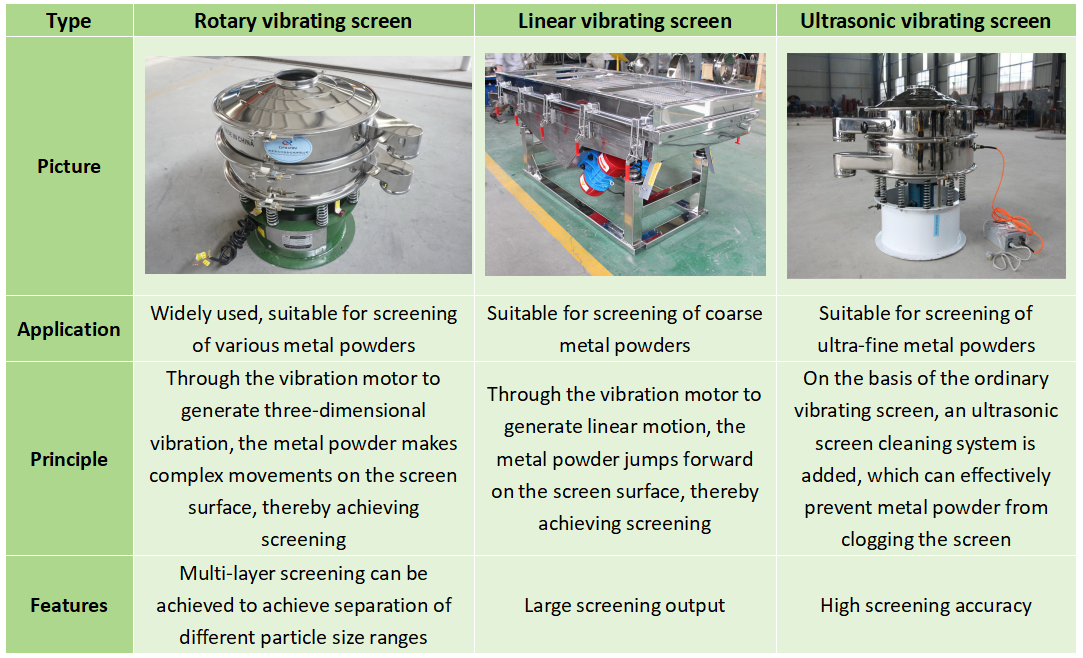

② Lightweight fine vibrating screens: such as rotary vibrating screens, linear screens, ultrasonic vibrating screens, etc. This type of screening machine is more suitable for screening fine-grained materials such as metal powders

Classification by material running trajectory:

What are the advantages of vibrating screens for metal powder screening?

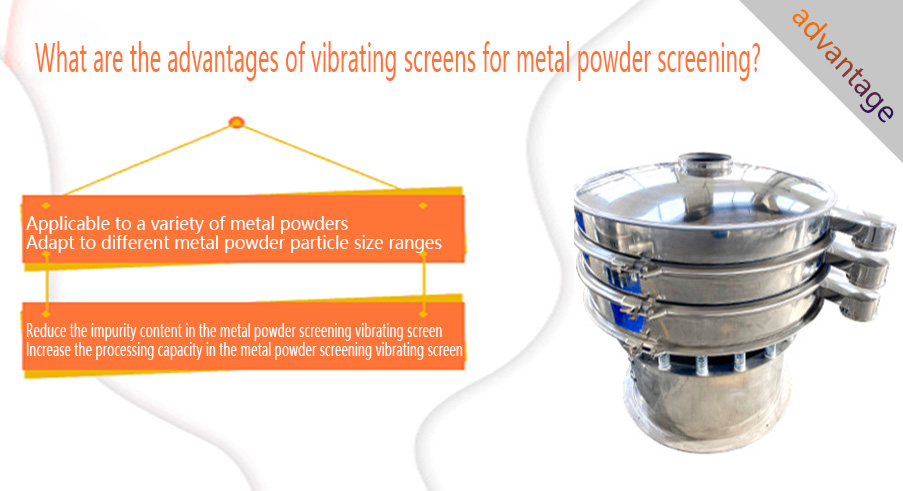

1. Applicable to a variety of metal powders: Vibrating screens for metal powder screening is suitable for the screening of a variety of metal powders such as stainless steel, titanium alloy, aluminum alloy, etc., and the vibration parameters can be adjusted according to the characteristics of different powders to achieve the best screening effect.

2. Adapt to different metal powder particle size ranges: Vibrating screens for metal powder screening can be equipped with screens of different apertures to meet the screening needs of metal powders in different particle size ranges.

3. Reduce the impurity content in the metal powder screening vibrating screen: Through the screening effect of vibrating screens for metal powder screening, impurities and unqualified particles in the metal powder can be effectively removed, and the purity and quality of the metal powder can be improved.

4. Increase the processing capacity in the metal powder screening vibrating screen: Compared with traditional screening methods, vibrating screens for metal powder screening has a larger processing capacity and can complete the screening of a large amount of metal powder in a short time to meet the needs of large-scale production.

Application of vibrating screens for metal powder screening

1. Metal powder production and processing: Vibrating screen for metal powder screening can be used to screen and grade metal powders of different particle sizes, remove impurities, separate metal powders of different particle sizes, and ensure the stability of the processing process and product quality.

2. Metal powder coating and spraying: Vibrating screen for metal powder screening can be used to screen metal powders of appropriate particle size to ensure uniform coating effect and moderate particle size. It can also be used to screen and grade metal powders to ensure the uniformity and stability of particle size during spraying.

3. Preparation of composite materials from metal powder: Vibrating screen for metal powder screening can be used to screen and separate metal powders and other additives to ensure the uniformity and performance stability of composite materials.

4. Metal powder recycling: Metal powder vibrating screen can be used to screen and separate metal powders of different particle sizes to improve the reuse rate of metal powders.

Purchase suggestions for vibrating screen for metal powder screening

Understand the needs: Before purchasing, the particle size, output, use and other requirements of the screened metal powder should be clarified in order to select the appropriate vibrating screen model.

Investigate the manufacturer: Choose a manufacturer with production qualifications, technical strength and production experience to ensure the quality of the equipment and after-sales service.

On-site test machine: Before purchasing, it is best to conduct an on-site test machine to check the vibration stability, screening effect and noise of the equipment.

Sign a contract: Clarify the price, delivery period, after-sales service and other terms of the equipment, and sign a formal contract to protect the rights and interests of both parties.

Vibrating screen for metal powder screening shows many significant highlights in the screening process, which makes the equipment have irreplaceable advantages in the metal powder processing and production process.

-

Potato Starch Vibrating Screen

Granules, powders, and paddle materials can be used.

-

Screening black soldier fly feces and larvae can separate the worms and feces, saving labor.

-

Ensures removal of contaminants such as large particles and agglomerates from metal powders, providing accurate particle size distribution

-

Remove solids from liquid slurries and recover valuable materials in the waste stream for reuse.

-

Vibrating screen for clay screening

Vibrating screen for clay screening is a screening device specially designed to handle sticky, easily agglomerated...

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Nylon sieve

Nylon sieve is a common screening tool, widely used in laboratories and industrial production, mainly used for screening...

-

Drying sand vibrating screen

Drying sand vibrating screen is a vibrating screening device specially used for screening dried sand. It is mainly...

-

Stone powder vibrating screen

Drying sand vibrating screen is a screening device that uses the exciting force generated by the vibrating motor to...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.