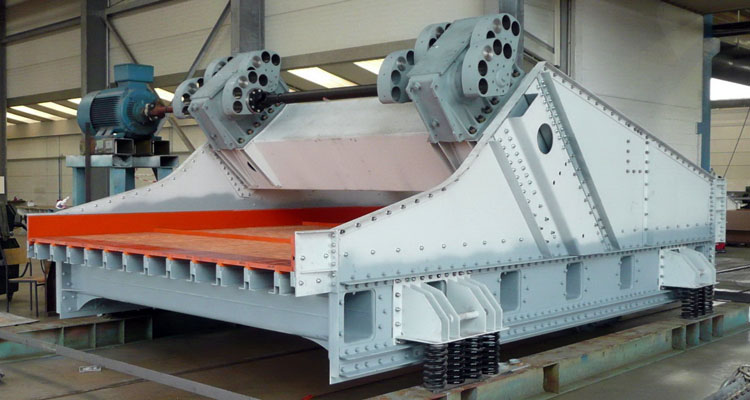

Vibrating screen for clay screening

Vibrating screen for clay screening is a screening device specially designed to handle sticky, easily agglomerated or high-humidity materials. Due to its special physical properties (such as stickiness, high humidity, and easy agglomeration), clay is prone to blockage and low screening efficiency during the screening process. Therefore, vibrating screen for clay screening needs to have special design and functions to ensure efficient and stable screening effects.

Vibrating screen for clay screening video

How does the vibrating screen for clay screening work?

Vibrating screen for clay screening generates vibration through a vibrating motor or exciter, so that the clay particles on the screen surface move on the screen, thereby achieving particle size classification. Its working principle includes:

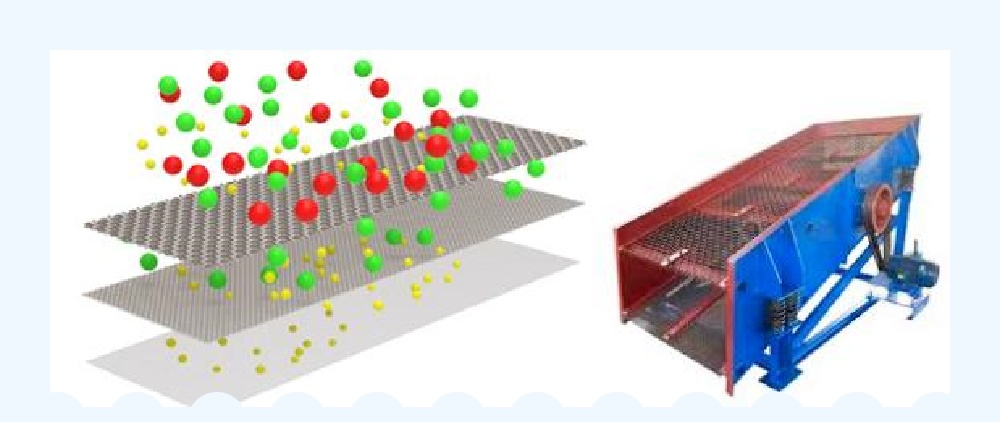

①Vibration source: the motor or exciter generates vibration.

②Screen: Screens with different apertures are used to separate clays of different particle sizes.

③Screening process: Clay jumps on the screen surface, clay particles smaller than the size of the screen hole pass through the screen, and clay particles larger than the size of the screen hole remain on the screen surface.

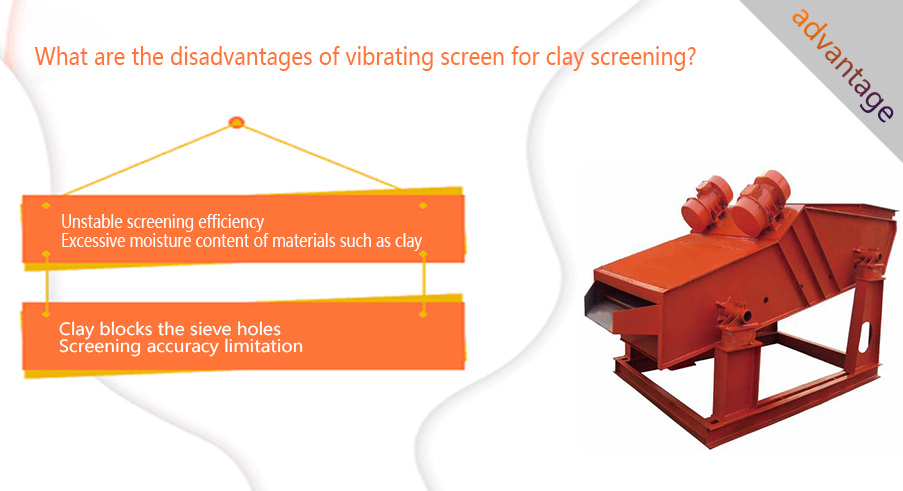

What are the disadvantages of vibrating screen for clay screening?

Unstable screening efficiency: The amplitude and frequency of the vibrating screen used for clay screening are key factors affecting screening efficiency. If the amplitude and frequency are not set properly, the screening efficiency may be unstable and even affect the screening quality.

Excessive moisture content of materials such as clay: Excessive moisture content of clay will reduce the fluidity and screening efficiency of the material, and may even easily cause the sieve holes to be blocked. This requires corresponding drying measures to be taken during the screening process, but it will also increase the processing cost and complexity.

Clay blocks the sieve holes: Clay is easy to form adhesion on the sieve holes due to its high viscosity and humidity, causing the sieve holes to be blocked. Some components in this clay, such as clay minerals, will also adhere to a large amount of fine particles after agglomeration, which is difficult to remove.

Screening accuracy limitation: For some particularly fine clay particles, the vibrating screen used for clay screening may not be able to completely separate them, reducing the screening accuracy.

Recommended mesh number of vibrating screen for clay screening

1. Coarse screening stage

Mesh number range: 20~60 mesh

Application scenario: Screening at this stage is mainly used to remove large impurities and coarse particles in clay for subsequent processing. Suitable for preliminary crushing of clay and separation of impurities.

2. Medium screening stage

Mesh number range: 80~120 mesh

Application scenario: Screening at this stage is used to further refine clay particles and improve the uniformity and fineness of clay. Suitable for making products that require a certain degree of fineness, such as fragrant mud and ceramic raw materials.

3. Fine screening stage

Mesh number range: 120~200 mesh and above

Application scenario: When it is necessary to make very fine clay products, such as advanced ceramics, precision casting sand, etc., 120~200 mesh or even finer screens can be used for screening.

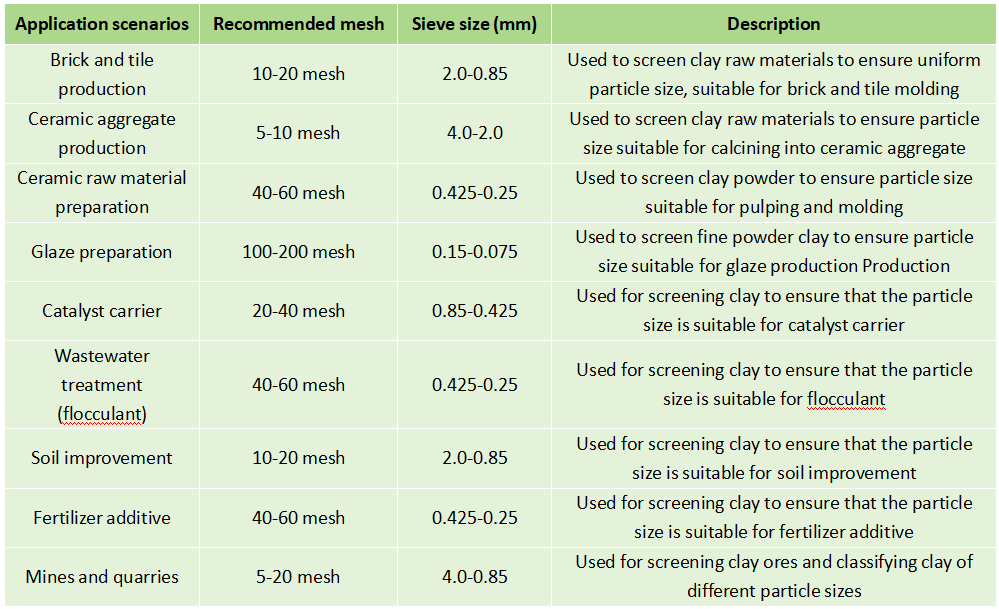

Application of vibrating screen for clay screening

1. Ceramic industry: The vibrating screen for clay screening can adjust the size of the sieve hole according to production needs, and screen the clay with different particle sizes, so as to meet the high requirements of ceramic products for raw materials.

2. Building materials industry: The vibrating screen for clay screening can screen powdered raw materials, and is used to screen building raw materials such as clay, sand, limestone, etc., to ensure the quality and uniformity of raw materials during the production process.

3. Mining and mineral processing: Vibrating screens for clay screening are widely used in the crushing, screening, classification and washing of ore. For ores containing clay components, the clay can be effectively separated from other minerals, which facilitates subsequent processing procedures.

4. Environmental protection industry: Vibrating screens for clay screening are used in wastewater treatment equipment, sludge screening and other scenarios. For sludge or wastewater containing clay components, the clay particles can be effectively separated, which helps to reduce environmental pollution and improve the efficiency of wastewater treatment.

Recommended technical parameters of vibrating screens for clay screening in different scenarios

Notes on vibrating screens for clay screening

1. Choose the right screen material: The screen material has a great influence on the screening effect. For clay screening, it is recommended to choose a wear-resistant, corrosion-resistant, and non-deformable screen material, such as stainless steel mesh.

2. Adjust the screening parameters according to the characteristics of the clay: The humidity, viscosity and other characteristics of the clay will affect the screening effect. In actual operation, it is necessary to adjust the amplitude, frequency and other parameters of the vibrating screen according to the specific characteristics of the clay to obtain the best screening effect.

The core function of vibrating screen used for clay screening is to efficiently and accurately grade the clay raw materials and remove impurities to meet the production needs of different industrial fields. Since clay has a certain viscosity and humidity, some special problems will be encountered during the screening process, and it is necessary to select and use the vibrating screen in a targeted manner.

-

Potato Starch Vibrating Screen

Granules, powders, and paddle materials can be used.

-

Screening black soldier fly feces and larvae can separate the worms and feces, saving labor.

-

Ensures removal of contaminants such as large particles and agglomerates from metal powders, providing accurate particle size distribution

-

Remove solids from liquid slurries and recover valuable materials in the waste stream for reuse.

-

Vibrating screen for coal powder screening

Vibrating screen for coal powder screening is a device used to classify coal powder by particle size, and...

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Nylon sieve

Nylon sieve is a common screening tool, widely used in laboratories and industrial production, mainly used for screening...

-

Drying sand vibrating screen

Drying sand vibrating screen is a vibrating screening device specially used for screening dried sand. It is mainly...

-

Stone powder vibrating screen

Drying sand vibrating screen is a screening device that uses the exciting force generated by the vibrating motor to...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.