Vibrating screen for coal powder screening

Vibrating screen for coal powder screening is a device used to classify coal powder by particle size, and is widely used in coal, electricity, chemical and other industries. The vibration force generated by the vibration motor or exciter separates the coal powder on the screen surface according to different particle sizes, thereby achieving the purpose of screening.

Video of vibrating screen for coal powder screening

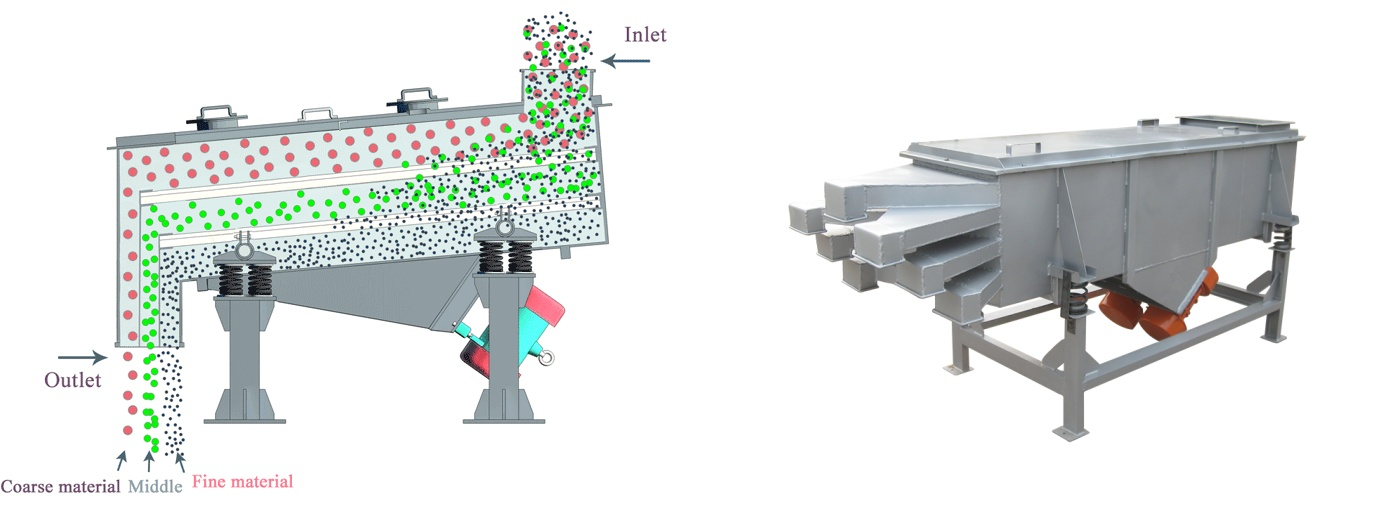

What is the working principle of vibrating screen for coal powder screening?

Vibrating screen for coal powder screening generates periodic vibration through a vibration motor or exciter, causing the screen box and screen to generate high-frequency vibration. The coal powder is subjected to the vibration force on the screen surface, and the fine coal powder particles fall into the lower layer through the screen, while the coarse coal powder particles remain on the screen surface and are finally discharged from the discharge port, thereby achieving the particle size classification of the coal powder.

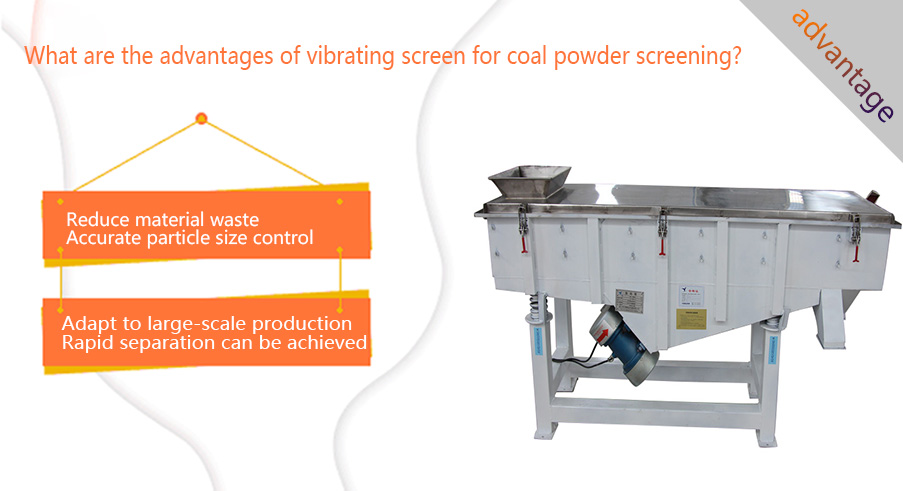

What are the advantages of vibrating screen for coal powder screening?

1、Reduce material waste: Through fine screening, the fine particles in the coal powder can be fully recovered to reduce material waste. The coal powder after screening has uniform particle size, which is convenient for subsequent processing or combustion and improves resource utilization.

2、Accurate particle size control: According to the particle size requirements of coal powder, screens with different apertures can be selected to ensure screening accuracy. The vibration mode of vibrating screen for coal powder screening makes the coal powder evenly distributed on the screen surface, avoiding local accumulation and ensuring the consistency of the screening results.

3、Adapt to large-scale production: The design of vibrating screen for coal powder screening can handle a large amount of coal powder to meet the needs of industrialized production, and is particularly suitable for large-scale production scenarios such as coal and electricity. The equipment can run continuously without frequent shutdowns to ensure the continuity of the production line.

4、Rapid separation can be achieved: Vibrating screen for coal powder screening uses high-frequency vibration to make the coal powder move quickly on the screen surface, and fine particles quickly pass through the screen, and coarse particles are separated. Multi-layer screens can be designed according to needs to complete multi-level particle size classification at one time.

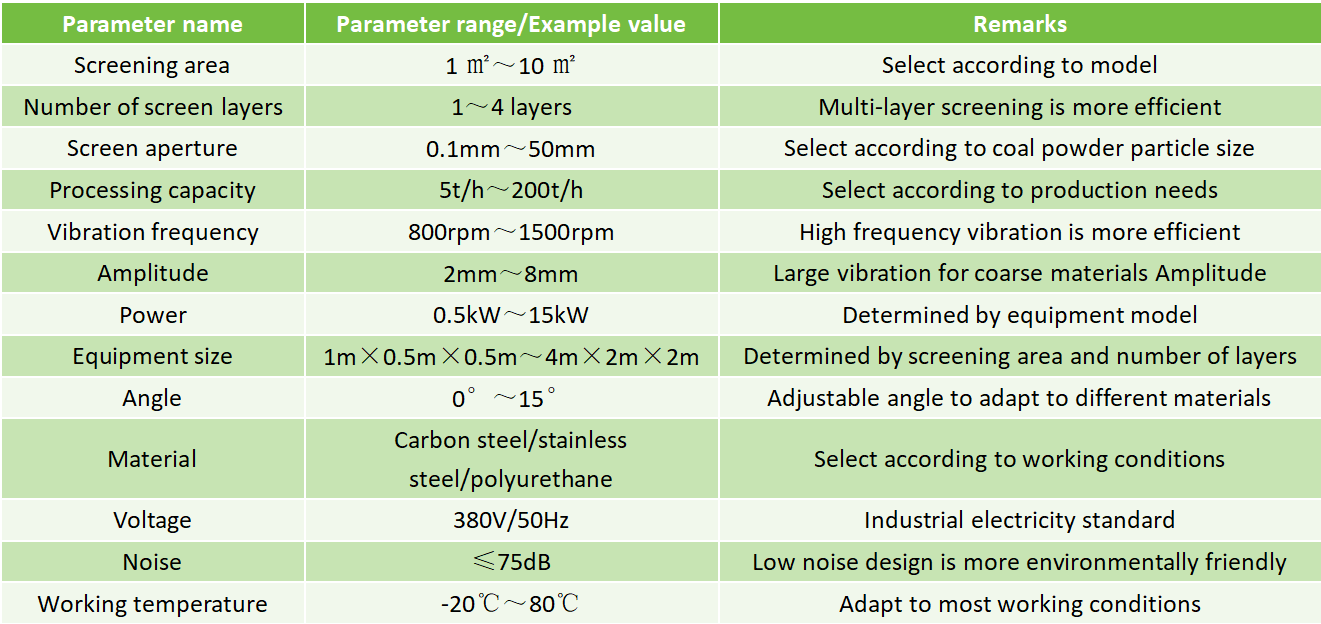

Related parameters of vibrating screen for coal powder screening

Application of vibrating screen for coal powder screening

1. Blast furnace coal injection system: In the blast furnace ironmaking process, coal powder needs to be injected into the blast furnace through the coal injection system as fuel and reducing agent. Vibrating screen for coal powder screening is used to screen the coal powder entering the coal injection system, remove wood chips, stones, etc., and ensure the uniform particle size and purity of the coal powder.

2. Thermal power generation coal powder preparation system: Coal needs to be ground into coal powder by a coal mill, and then sent to the boiler for combustion to generate steam to drive the steam turbine to generate electricity. Vibrating screen for coal powder screening is installed in the coal powder preparation system to screen the ground coal powder and control the particle size distribution of the coal powder.

3. Coal gasification process: Vibrating screen for coal powder screening is used to screen the coal powder entering the gasifier to ensure the particle size and purity of the coal powder, which is conducive to the smooth progress of the gasification reaction, improve the yield and quality of coal gas, and provide qualified raw gas for subsequent chemical production.

4. Coal powder classification: In the process of coal washing and processing, the coal powder needs to be classified according to different particle sizes. Vibrating screen for coal powder screening can classify the pulverized coal into products of different particle sizes, such as coarse powder, medium powder, fine powder, etc., according to the set sieve hole size, so as to realize the refined processing and utilization of the pulverized coal.

Particle size distribution range of vibrating screen for coal powder screening

For blast furnace coal injection: the particle size of coal powder is required to be less than 0.074mm (i.e. 200 mesh) and the content of particles is usually about 70%-90%

For thermal power generation: the particle size of coal powder is generally required to be 70%-80% less than 0.074mm, and some particles are between 0.074mm-0.15mm

For coal gasification: the particle size distribution of coal powder is generally required to be less than 0.1mm, usually about 60%-80%, and there will also be a certain proportion of slightly larger particles.

Through reasonable selection, correct operation and regular maintenance, vibrating screen for coal powder screening can efficiently and stably complete the coal powder screening task and provide strong support for industrial production.

-

Potato Starch Vibrating Screen

Granules, powders, and paddle materials can be used.

-

Screening black soldier fly feces and larvae can separate the worms and feces, saving labor.

-

Ensures removal of contaminants such as large particles and agglomerates from metal powders, providing accurate particle size distribution

-

Remove solids from liquid slurries and recover valuable materials in the waste stream for reuse.

-

Vibrating screen for ore sand screening

Vibrating screen for ore sand screening is a device used to grade and screen granular materials...

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Nylon sieve

Nylon sieve is a common screening tool, widely used in laboratories and industrial production, mainly used for screening...

-

Drying sand vibrating screen

Drying sand vibrating screen is a vibrating screening device specially used for screening dried sand. It is mainly...

-

Stone powder vibrating screen

Drying sand vibrating screen is a screening device that uses the exciting force generated by the vibrating motor to...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.