Vibrating screen for ore sand screening

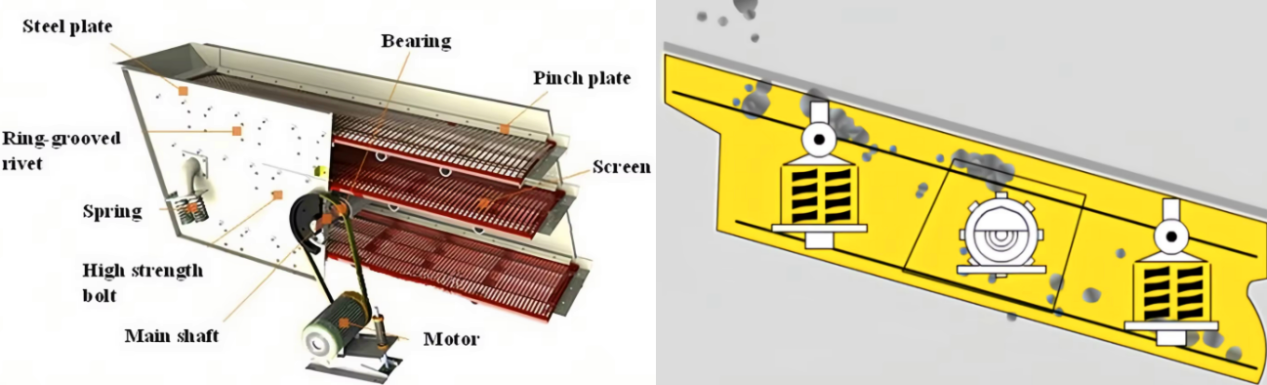

Vibrating screen for ore sand screening is a grading equipment specially used for screening ore sand (ore sand material). It is widely used in mining, metallurgy, building materials and other industries. Its main function is to separate ore sand according to particle size through vibration to meet different process requirements. Ore sand usually has the characteristics of different particle sizes, high hardness, and large changes in water content. Therefore, vibrating screen for ore sand screening needs to have the characteristics of high efficiency, durability, and strong adaptability.

Video of vibrating screen for ore sand screening

Working principle of vibrating screen for ore sand screening

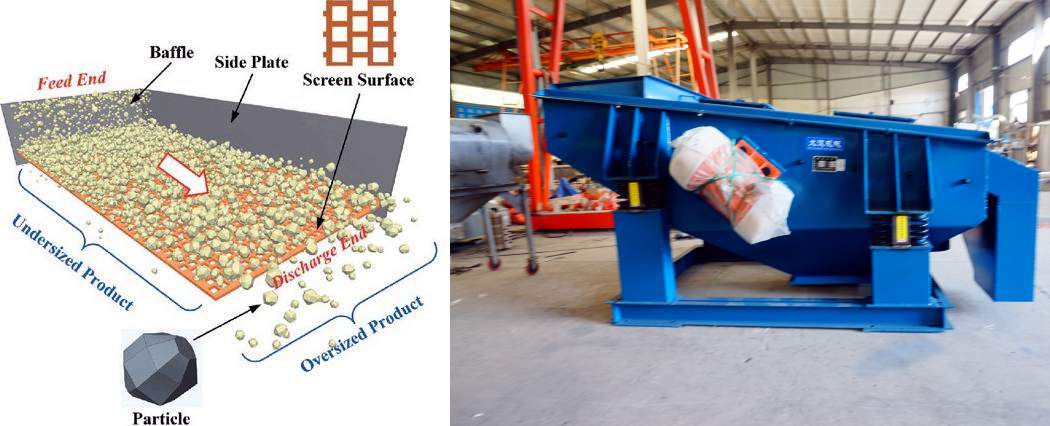

① Feeding of granular materials: ore or ore granular materials enter the screening area of the vibrating screen from the feed port.

② Vibration screening: The equipment generates screening movement through vibration, so that the ore sand is quickly transmitted and separated on the screen. Smaller particle size ore sand passes through the screen, while larger particle size ore sand is blocked on the screen.

③ Separation of particles: Ore sand of different particle sizes is separated under the action of vibration, fine particles pass through the screen, and coarse particles are blocked.

④ Collecting separated materials: The ore sand after screening and separation is collected in different discharge ports or containers for further processing or use.

The role of vibrating screen for ore sand screening

Vibrating screen for ore sand screening is a professional screening equipment that separates the ore sand by particle size through vibration force, and removes impurities or materials that do not meet the specifications. It is mainly used for grading, impurity removal, dehydration, and powder removal of ore sand after ore crushing to ensure that it meets the particle size requirements of different industrial applications.

What are the advantages of vibrating screen for ore sand screening?

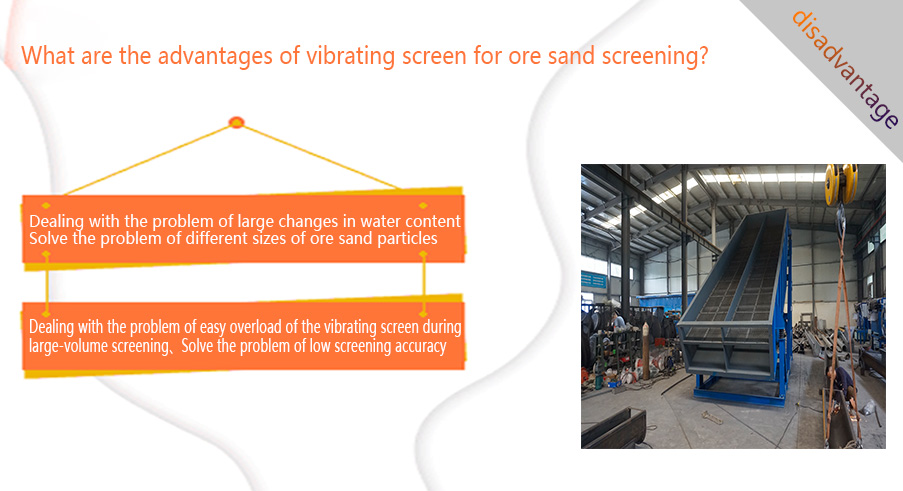

1. Dealing with the problem of large changes in water content: The large change in water content of ore sand may cause the screen to be blocked or the screening efficiency to decrease. Vibrating screen for ore sand screening uses high-frequency and low-amplitude vibration to prevent wet ore sand from adhering to the screen and reduce blockage.

2. Solve the problem of different sizes of ore sand particles: The large difference in the size of ore sand particles may lead to low screening efficiency or incomplete screening. Vibrating screen for ore sand screening is usually equipped with multiple layers of screens (1-5 layers to ensure that ore sands of different particle sizes are effectively separated.

3. Dealing with the problem of easy overload of the vibrating screen during large-volume screening: The screening capacity of a single vibrating screen can reach 200-500 tons/hour, and long-term operation of the equipment will cause overload. Use thickened plates, welded reinforcements, etc. to improve the durability of vibrating screen for ore sand screening.

4. Solve the problem of low screening accuracy: For quartz sand, machine-made sand and other ore sand industries, strict separation of different particle sizes is required, otherwise it will affect product quality. Vibrating screen for ore sand screening can reasonably tighten the screen to ensure that the material can be evenly distributed and improve the screening accuracy.

Recommended mesh number of vibrating screen for ore sand screening

Coarse-grained ore (such as iron ore, copper ore): mesh number is 2 to 10 (sieve hole size is about 10mm to 2mm). Coarse-grained ore has a larger particle size, and using a larger sieve hole can improve screening efficiency.

Medium-grained ore (such as gold ore, limestone): mesh number is 10 to 40 (sieve hole size is about 2mm to 0.42mm). Medium-grained ore has a moderate particle size, and using a medium sieve hole can ensure screening efficiency. Results.

Fine-grained ore sand (such as quartz sand, bentonite): mesh size is 40 to 100 mesh (sieve size is about 0.42mm to 0.15mm). Fine-grained ore sand has a small particle size, and using a smaller sieve hole can improve the screening accuracy.

Ultrafine-grained ore sand (such as tailings, chemical raw materials): mesh size is 100 to 200 mesh (sieve size is about 0.15mm to 0.075mm). Ultrafine-grained ore sand has a very small particle size, and using a very small sieve hole can ensure the screening effect.

Application of vibrating screen for ore sand screening

1. Iron ore screening (ore dressing industry): After crushing and grinding, iron ore needs to be screened to separate iron ore of different particle sizes. Vibrating screen for ore sand screening separates large pieces of ore from qualified ore to ensure that the ore entering the grinding process meets the particle size requirements.

2. Machine-made sand Screening (construction industry): Artificial sand is made by crushing ore, and sand of different particle sizes needs to be screened for concrete and construction projects. Vibrating screen for ore sand screening removes oversized particles and stone powder to ensure that the machine-made sand meets the construction standards (such as 0-5mm, 5-10mm, 10-20mm different specifications).

3. River sand and sea sand screening (sand and gravel industry): Natural river sand and sea sand contain a lot of soil, shells and other impurities, which need to be screened and removed. Vibrating screen for ore sand screening removes soil, impurities, shells and other non-sand components to improve the quality of sand.

4. Gold ore sand and copper ore sand screening (metallurgical industry): Gold, copper and other ores need to be screened before smelting to improve extraction efficiency. Vibrating screen for ore sand screening can effectively screen ore sand that meets smelting standards and improve metal recovery rate.

Vibrating screen for ore sand screening is an indispensable equipment in mining, metallurgy, building materials and other industries. It improves the utilization rate and product quality of ore sand through efficient screening. Reasonable selection of screen mesh size, attention to equipment maintenance and optimization of operating parameters can significantly improve screening effect and equipment performance to meet the needs of different application scenarios.

-

Potato Starch Vibrating Screen

Granules, powders, and paddle materials can be used.

-

Screening black soldier fly feces and larvae can separate the worms and feces, saving labor.

-

Ensures removal of contaminants such as large particles and agglomerates from metal powders, providing accurate particle size distribution

-

Remove solids from liquid slurries and recover valuable materials in the waste stream for reuse.

-

Vibrating screen for ore sand screening

Vibrating screen for ore sand screening is a device that uses vibration separation technology to clas ...

-

Vibrating screen for chemical powder screening

Vibrating screen for chemical powder screening refers to the equipment used in the chemical industry...

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Nylon sieve

Nylon sieve is a common screening tool, widely used in laboratories and industrial production, mainly used for screening...

-

Drying sand vibrating screen

Drying sand vibrating screen is a vibrating screening device specially used for screening dried sand. It is mainly...

-

Vibrating screen for coal gangue screening

Vibrating screen for coal gangue screening is a kind of equipment specially used for grading and screening of...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.