Vibrating screen for limestone screening

Vibrating screen is a kind of equipment commonly used for screening granular materials, and is suitable for screening operations of limestone and other ores. The purpose of vibrating screen for limestone screening is to separate limestone of different particle sizes to meet the needs of different industrial and production purposes (such as building materials, chemical raw materials, etc.). Due to the characteristics of limestone, such as high hardness and uneven particle size distribution, some special problems will be encountered during the screening process, and it is necessary to select and use the vibrating screen in a targeted manner.

Video of vibrating screen for limestone screening

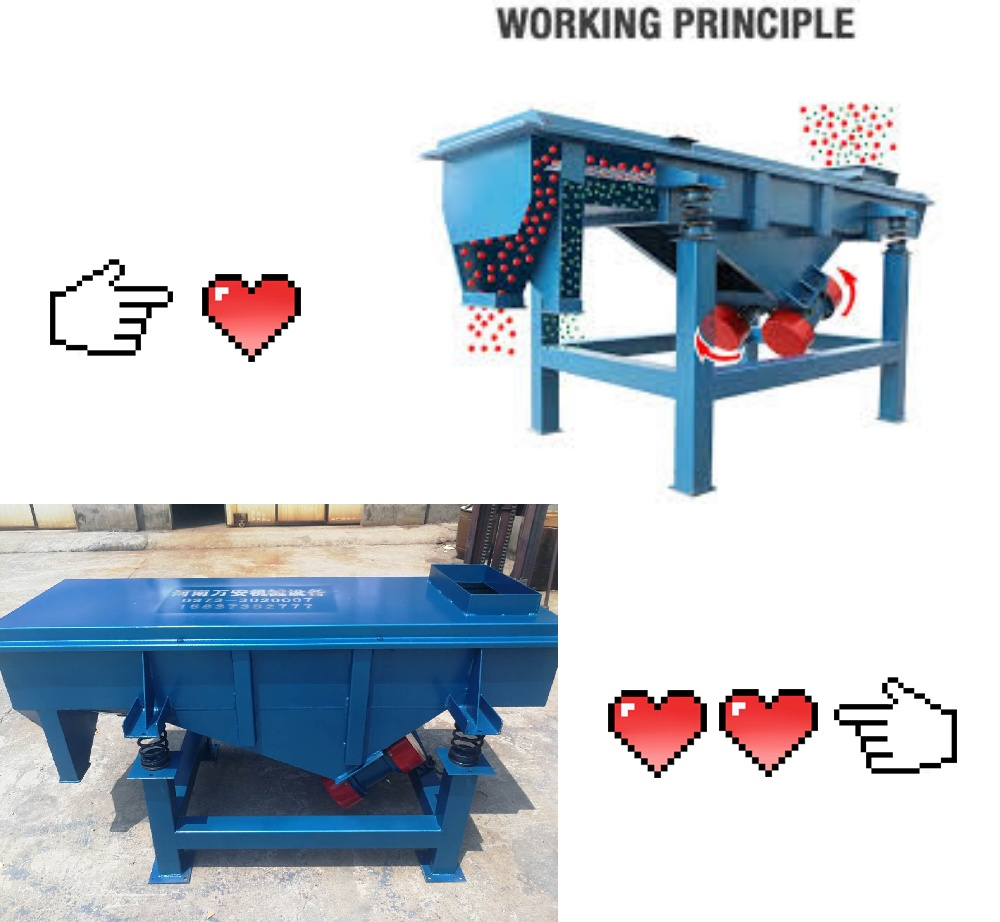

What is the working principle of vibrating screen for limestone screening?

① The vibrating screen drives the vibrator through the motor to make the screen body vibrate at high frequency.

② The limestone material is subjected to the vibration force on the screen surface, causing it to jump and loosen.

③ Particles smaller than the size of the screen hole pass through the screen, while particles larger than the size of the screen hole remain on the screen surface, thereby achieving material classification.

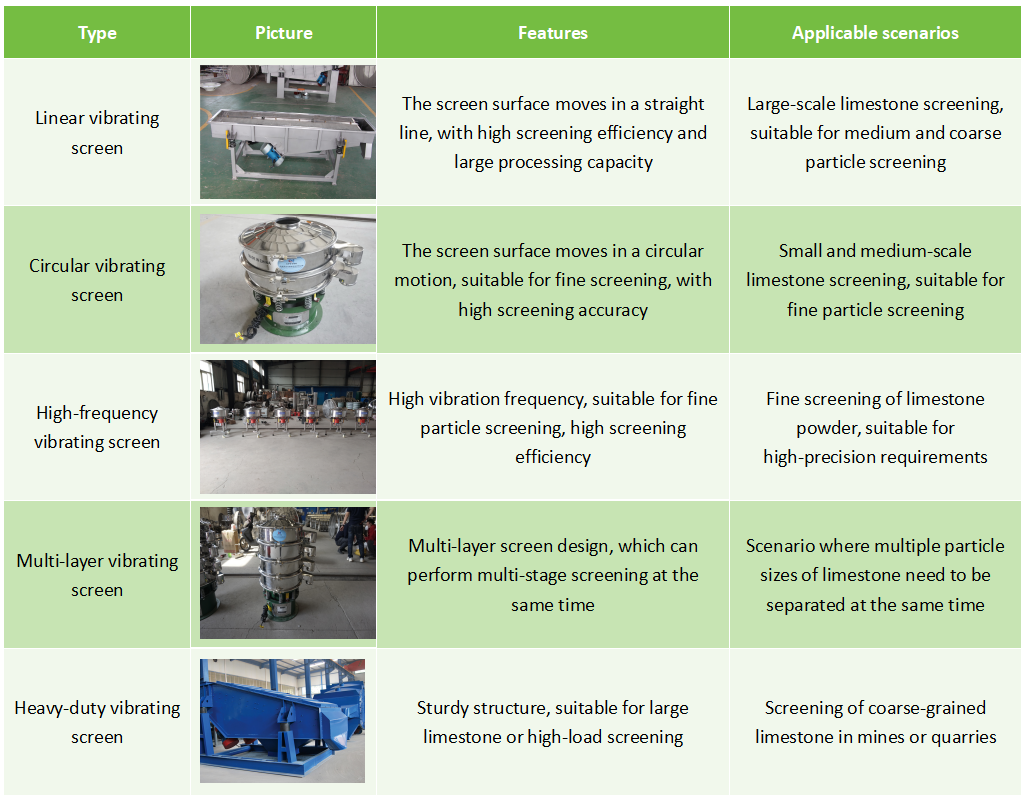

What types of vibrating screens are used for limestone screening?

According to the structure and function, vibrating screens for limestone screening used for limestone screening can be divided into the following types:

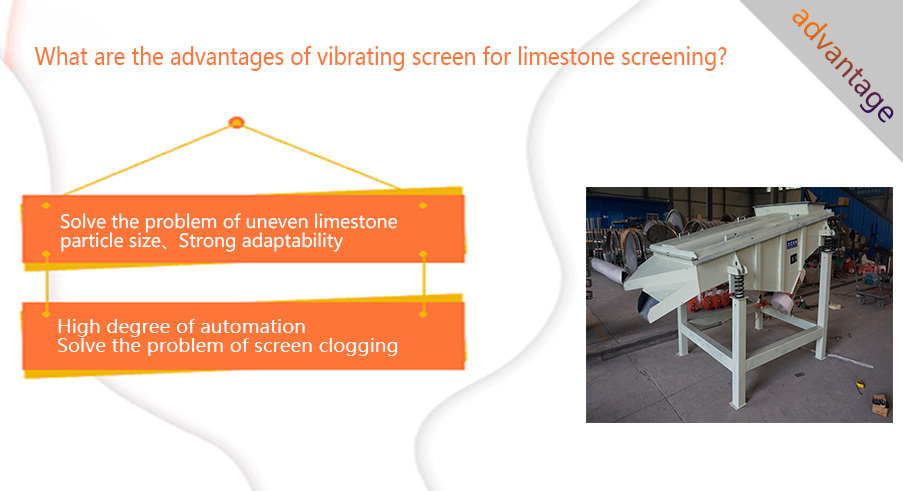

What are the advantages of vibrating screen for limestone screening?

1、Solve the problem of uneven limestone particle size: Uneven limestone particle size will lead to poor screening effect. Through high-frequency vibration, the limestone particles are made to jump on the screen surface, thereby achieving effective particle separation.

2、Strong adaptability: The physical and chemical properties of limestone vary greatly, and the requirements for screening equipment are also high. The vibrating screen used for limestone screening has strong adaptability and can be customized according to the characteristics of limestone and screening requirements.

3、High degree of automation: The vibrating screen used for limestone screening can be equipped with advanced automatic control systems to improve screening efficiency and reduce operating difficulty and labor costs.

4、Solve the problem of screen clogging: The vibrating screen used for limestone screening can achieve effective separation of particles through high-frequency vibration, and can also effectively prevent screen clogging. It has the characteristics of wear resistance, corrosion resistance, and not easy to clog.

Application of vibrating screen for limestone screening

1. Mining and primary processing: Use vibrating screens to preliminarily screen the coarsely crushed limestone, remove large pieces of waste rock and impurities, and classify the limestone into grades of different particle sizes to prepare for subsequent fine crushing and deep processing.

2. Construction material production: Vibrating screens are used to finely screen the limestone raw materials to ensure that the particle size of the limestone entering the cement mill meets the requirements, so as to meet the ratio requirements of concrete of different strength grades in the later stage.

3. Chemical industry: In the production process of soda ash, limestone, as an important raw material, needs to be screened to ensure that its particle size meets the requirements of the carbonization reaction.

4. Metallurgical industry: In the steelmaking process, limestone is used as a flux to remove impurities in molten steel. Vibrating screens are used to screen out limestone with suitable particle size to improve steelmaking efficiency.

Selection suggestions for vibrating screen for limestone screening

1. Analysis of limestone characteristics

① Particle size range: Determine the particle size distribution of limestone (such as 0-5 mm, 5-20 mm, 20-50 mm, etc.).

② Humidity: Dry limestone or wet limestone affects the screening method (dry or wet).

③ Impurity content: If the limestone contains soil or other impurities, a wear-resistant and anti-clogging screen needs to be selected.

2. Equipment parameter selection: screening capacity, number of screen layers, screen aperture, vibration frequency and amplitude, and motor power

3. Material selection: Stainless steel is corrosion-resistant and wear-resistant, suitable for wet or corrosive environments, and manganese steel is highly wear-resistant and suitable for large limestone screening. Carbon steel has low cost and is suitable for dry environments

Precautions for vibrating screen for limestone screening

Before starting the screen, check whether there are obstacles around that may hinder the operation of the screen, and ensure that the connecting bolts are tightened.

The screen should be started with no load and run for a period of time to observe whether there are any abnormal phenomena and sounds.

When running with material, the feeding should be uniform to avoid material deviation or clogging the screen holes.

The vibration motor needs to be refueled and maintained regularly to ensure its normal operation and extend its service life.

Vibrating screen for limestone screening can meet the screening needs of different industries through reasonable selection and configuration.

-

Potato Starch Vibrating Screen

Granules, powders, and paddle materials can be used.

-

Screening black soldier fly feces and larvae can separate the worms and feces, saving labor.

-

Ensures removal of contaminants such as large particles and agglomerates from metal powders, providing accurate particle size distribution

-

Remove solids from liquid slurries and recover valuable materials in the waste stream for reuse.

-

Vibrating screen for clay screening

Vibrating screen for clay screening is a screening device specially designed to handle sticky, easily agglomerated...

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Nylon sieve

Nylon sieve is a common screening tool, widely used in laboratories and industrial production, mainly used for screening...

-

Drying sand vibrating screen

Drying sand vibrating screen is a vibrating screening device specially used for screening dried sand. It is mainly...

-

Stone powder vibrating screen

Drying sand vibrating screen is a screening device that uses the exciting force generated by the vibrating motor to...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.