Vibrating screen for organic fertilizer screening

Vibrating screen for organic fertilizer screening is a device used in the production process of organic fertilizer, which is used to screen, classify and remove impurities from. It is mainly used to screen and classify the particles in the raw materials of organic fertilizer. It uses vibration to separate fertilizer particles of different sizes on the screen, as to achieve the purpose of screening. This kind of equipment helps to improve the quality of organic fertilizer, remove impurities and uneven particles, and thus produce higher quality fertilizer products.

Video of vibrating screen for organic fertilizer screening

What is the working principle of vibrating screen for organic fertilizer screening?

Vibrating screen for organic fertilizer screening is composed of a vibrating motor, a screen, screen box, a feed port, and a discharge port. The vibrating motor generates a force through vibration, which makes the organic fertilizer in the screen box vibrate and on the screen. According to different screen hole sizes, the organic fertilizer can be divided into different particle sizes to meet the needs of different crops for fertilizer particle size

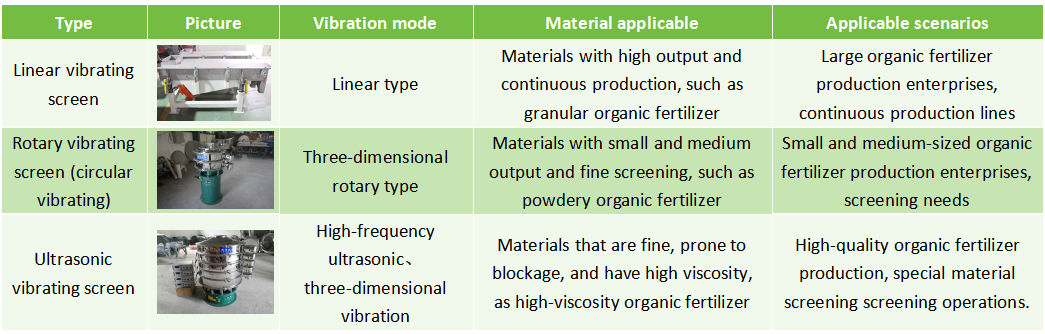

What types of vibrating screens for organic fertilizer screening are there?

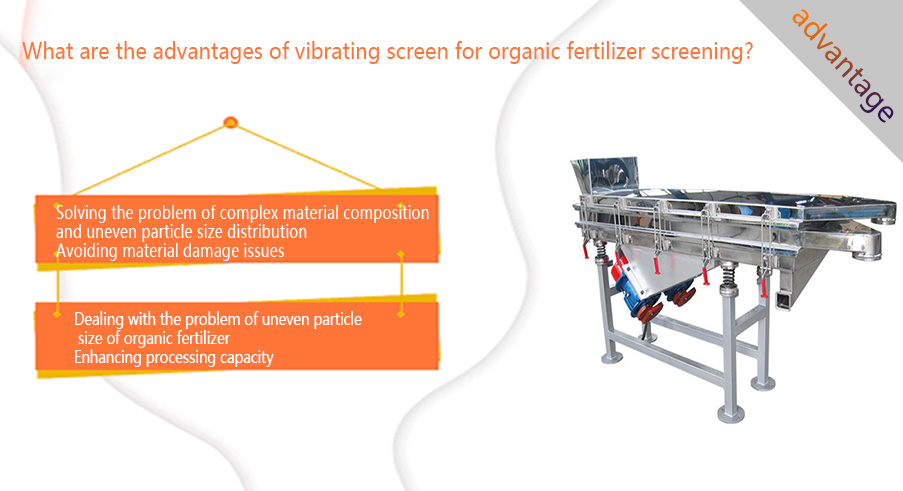

What are the advantages of vibrating screen for organic fertilizer screening?

1. Solving the problem of complex material composition and uneven particle size distribution: The raw materials of organic fertilizer come from a wide of sources, with complex composition and uneven particle size distribution, which requires precise grading. Vibrating screen for organic fertilizer screening can control the movement trajectory and residence time of organic fertilizer the screen by adjusting the vibration frequency and amplitude, improving the screening accuracy.

2. Dealing with the problem of uneven particle size of organic fertilizer: The particle of organic fertilizer varies, affecting the screening effect and the efficiency of fertilizer use. The organic fertilizer vibrating screen is usually equipped with multi-layer screens with different aperture sizes, can grade the fertilizer according to particle size, ensuring uniform particles.

3. Avoiding material damage issues: During the screening process of vibrating screen for organic fertilizer screening, although vibration intensity is large, modern equipment usually adopts advanced vibration technology and materials, which can control the jumping and sliding intensity of materials on the screen, avoiding the fragile organic components from breaking or pulverizing due to strong vibration.

4. Enhancing processing capacity: Vibrating screen for organic fertilizer screening can process a large volume of organic fertilizer in unit. Due to the vibration, the movement speed of materials on the screen surface is fast, and they can quickly pass through the screen, so it is especially suitable for screening operations in large-scale production.

Parameters of the vibrating screen for organic fertilizer screening

Screening area: The effective screening area of the screen, which directly affects the processing capacity of the equipment, typically ranges from 05㎡ to 10㎡

Number of screen layers: The number of screen layers determines the number of material classifications, typically ranging from 1 layer to layers

Screen aperture: The size of the screen aperture determines the screening accuracy, typically ranging from 0.5mm to 20mm

Processing capacity: amount of material processed per unit time, typically ranging from 1 ton/hour to 50 tons/hour

Vibration frequency: The vibration frequency of the motor, which affects the screening efficiency and the material movement mode, typically ranges from 800 times/minute to 3000 times/minute

plitude: The amplitude of the vibrating screen, which affects the jumping height of the material and the screening effect, typically ranges from 2mm to 10mmPower: The power of the vibration motor, which affects the energy consumption and screening capacity of the equipment, typically ranges from 0.5kW to 1kW

Equipment size: The length, width, and height dimensions of the equipment, which affect installation and footprint, typically range from 1m to 5m in length, 0.5m to 2m in width, and 0.8m to 2.5m in

Application of vibrating screen for organic fertilizer screening

1. Organic Fertilizer Production Line: Vibrating screen for organic fertilizer screening is often used in the screening process of the production line. After the raw materials have been mixed and fermented, they enter the vibrating sieve machine for grading and screening, can remove impurities, substandard particles, and particles that are too large or too small, ensuring the quality and uniformity of the organic fertilizer.

2. Agricultural Resource Utilization: Agricultural waste can be converted into organic fertilizer after composting fermentation. Vibrating screen for organic fertilizer screening can screen the fermented organic fertilizer, remove impurities substandard particles, and improve the purity and utilization rate of the organic fertilizer.

3. Biomass Energy Production: Vibrating screen for organic fertilizer screening is widely used the production of biomass energy, such as wood chips, straw, etc. Before combustion, it needs to be screened to ensure that its particle size is uniform and burns. Vibrating screen for organic fertilizer screening provides reliable protection for the production of biomass energy.

4. Soil Improvement and Remediation: Vibrating screen for organic fertilizer screening can screen organic fertilizer accurately, obtaining particles of different sizes. These particles can be mixed and used according to the specific conditions of the soil to achieve the best soil improvement effect

Vibrating screen for organic fertilizer screening plays an important role in the production and application of organic fertilizers, improving the quality and utilization rate of organicizers through screening, grading, and impurity removal, and promoting the sustainable development of agriculture.

-

Potato Starch Vibrating Screen

Granules, powders, and paddle materials can be used.

-

Screening black soldier fly feces and larvae can separate the worms and feces, saving labor.

-

Ensures removal of contaminants such as large particles and agglomerates from metal powders, providing accurate particle size distribution

-

Remove solids from liquid slurries and recover valuable materials in the waste stream for reuse.

-

Vibrating screen for coal gangue screening

Vibrating screen for coal gangue screening plays a crucial role in the coal industry and related...

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Nylon sieve

Nylon sieve is a common screening tool, widely used in laboratories and industrial production, mainly used for screening...

-

Drying sand vibrating screen

Drying sand vibrating screen is a vibrating screening device specially used for screening dried sand. It is mainly...

-

Stone powder vibrating screen

Drying sand vibrating screen is a screening device that uses the exciting force generated by the vibrating motor to...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.