Food linear vibrating screen

Food linear vibrating screen is a screening device widely used in the food industry. It is mainly used to screen, grade or remove impurities from food raw materials or finished products. It uses linear vibration motion to separate raw materials into particles of different sizes according to particle size through the vibrating screen, thereby achieving the purpose of screening, filtering and grading to ensure the uniformity and quality of food.

Video of food linear vibrating screen

What is the purpose of a food linear vibrating screen?

1. Remove impurities: Through screening, food linear vibrating screen can remove impurities, foreign matter or bad particles in food raw materials, such as stones, soil, metal fragments, etc., to ensure the purity and safety of food.

2. Particle size classification: According to production needs, food linear vibrating screen can classify food raw materials or finished products according to particle size to meet the requirements of different products or processes. For example, flour is screened into different particle size grades to meet the needs of different baked products.

3. Adapt to diversified needs: The mesh aperture and number of layers of food linear vibrating screen can be customized according to actual needs to meet the screening needs of food raw materials of different types and specifications.

What is the principle of a food linear vibrating screen?

Food linear vibrating screen uses the principle of linear vibration to screen and classify food ingredients. When the vibration motor is started, the excitation force generated is transmitted to the screen box, causing it to vibrate linearly. The food ingredients are placed on the screen box and are affected by the vibration force, which will produce linear motion on the screen. Depending on the size of the screen aperture, smaller particles of food will pass through the screen holes, while larger particles or impurities will be blocked on the screen.

What are the advantages of food linear vibrating screen?

1. Solve the problem of insufficient food material production capacity: Through optimized design and vibration parameter adjustment, food linear vibrating screen can improve screening efficiency, increase production capacity, and meet the demand for production capacity in food production.

2. Adapt to different food characteristics: Food linear vibrating screen can design a variety of feeding and discharging methods according to the requirements of food processing technology. For example, the use of a spiral feeder can achieve uniform and stable feeding, avoiding the impact of too fast or too slow feeding on the screening effect; and the discharge port can be designed into multiple as needed, so that food materials of different particle sizes can be collected separately to meet different production needs.

3. Avoid food contamination: The parts of the food linear vibrating screen that come into contact with food, such as the screen box, screen, feed port, and discharge port, are all made of stainless steel and other materials that meet food hygiene standards. These materials have good corrosion resistance and stability, will not react chemically with food, and will not release harmful substances, ensuring the safety and hygiene of food during the screening process.

4. High processing precision requirements: Food linear vibrating screen has high-precision screening capabilities and can accurately distinguish food particles of different sizes to meet the precision requirements of particle size during food processing.

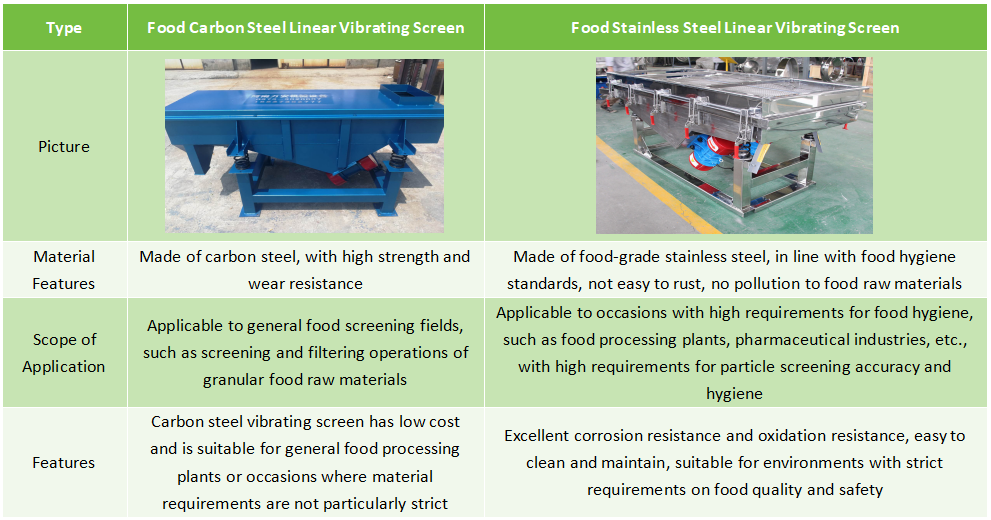

What are the different types of food linear vibrating screens?

Application of food linear vibrating screen

1. Grain processing: Food linear vibrating screen can screen and grade rice, wheat, corn and other grains, remove impurities, imperfect grains and foreign matter, and improve the quality and storage stability of grains. It can also be used for screening after grain grinding to ensure the uniform particle size of flour, rice flour and other products.

2. Condiment production: Food linear vibrating screen screens condiments such as salt, monosodium glutamate, pepper, chili powder, etc., remove lumps and impurities, make the particle size of condiments more uniform, and improve the quality and taste of products.

3. Fruit and vegetable processing: Food linear vibrating screen can be used to screen dehydrated vegetables, dried fruits, etc., remove broken particles and impurities, and ensure the appearance and quality of products. In the production of fruit and vegetable juice, it can also be used to filter pulp and residues.

4. Baking and other leisure food processing: Food linear vibrating screen screens baking raw materials such as flour, powdered sugar, cocoa powder, remove impurities and large particles, make the raw materials more delicate and uniform, which is conducive to the production and quality improvement of baked food. Screen snack foods such as potato chips, nuts, and candies to remove broken, deformed products and impurities, and improve the appearance quality and packaging effect of the products.

5. Dairy product processing: During the milk powder production process, the food linear vibrating screen screens skim milk powder, whole milk powder, etc. to remove lumps and foreign matter to ensure the particle uniformity and quality of the milk powder.

Food linear vibrating screen plays a key role in the food processing industry. Through efficient screening operations, it helps food production companies improve production efficiency and ensure food quality.

-

Swing Vibrating Screen is a high-efficiency screening machine specially designed to meet the needs of large-scale and high-precision screening.

-

Standard test sieves are precision mesh screens used to separate particles based on size in various industries, ensuring accurate particle size analysis and quality control.

-

Used to safely remove contaminants and lumps in powder

-

For separation of different particle sizes in the same product, safe screening to eliminate foreign matter, solid-liquid separation, etc.

-

Chemical catalyst vibrating screen

Chemical catalyst vibratinACg screen is a device specially used for screening and grading chemical catalyst...

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Nylon sieve

Nylon sieve is a common screening tool, widely used in laboratories and industrial production, mainly used for screening...

-

Drying sand vibrating screen

Drying sand vibrating screen is a vibrating screening device specially used for screening dried sand. It is mainly...

-

Stone powder vibrating screen

Drying sand vibrating screen is a screening device that uses the exciting force generated by the vibrating motor to...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.